Natural stone is revolutionizing sustainable architecture in 2024, transforming from a luxury accent into an essential component of eco-conscious building design. From carbon-neutral quarrying practices to innovative recycling techniques, the stone industry has embraced environmental stewardship while delivering unprecedented aesthetic versatility.

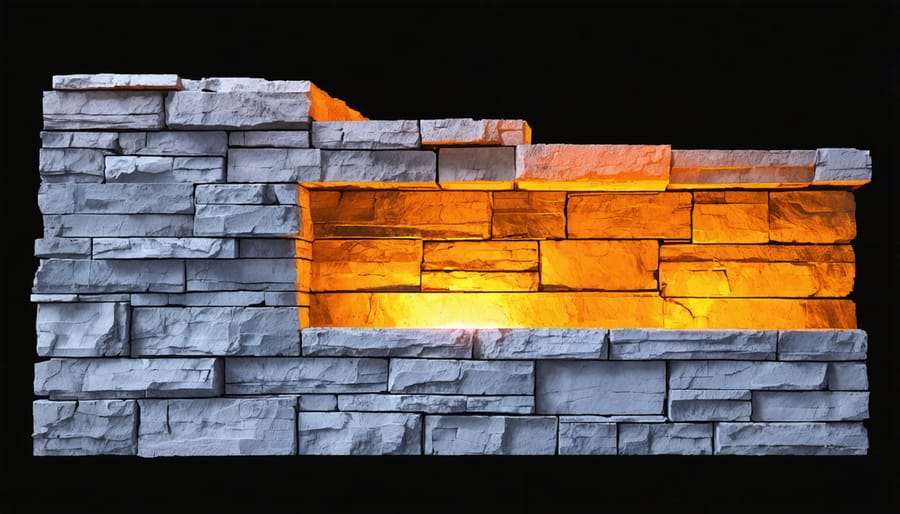

Today’s leading architects and designers are reimagining stone’s potential through groundbreaking applications: textured feature walls that regulate indoor temperatures naturally, precision-cut stone veneers that reduce material waste by 60%, and modular stone systems that enable future reuse. These innovations merge timeless beauty with measurable sustainability metrics that matter to modern builders and environmentally conscious clients.

The rise of digital fabrication has dramatically expanded stone’s design possibilities while minimizing its environmental impact. Computer-controlled cutting reduces waste to near-zero levels, while advanced finishing techniques create surfaces that are both visually striking and highly functional. Combined with stone’s inherent durability and thermal mass properties, these technological advances position natural stone as a cornerstone of sustainable construction for decades to come.

This convergence of traditional materials with cutting-edge technology represents more than a trend – it’s a fundamental shift in how we approach sustainable building materials in the modern era.

Local Sourcing: The New Normal in Stone Selection

Regional Stone Varieties

Every region boasts distinctive stone varieties that reflect its unique geological heritage. In North America, Vermont’s iconic green marble and Tennessee’s warm pink marble have become hallmarks of regional architecture. The Southwest celebrates its rustic sandstone in rich desert hues, while the Pacific Northwest is known for its durable granite and basalt formations.

European quarries produce sought-after varieties like Italian Carrara marble, prized for its pristine white coloring and subtle veining, and Spanish limestone known for its consistent pale tones. These classic materials continue to influence global design trends while supporting local economies through ethically sourced natural stone practices.

In Asia, materials like Indian sandstone and Chinese granite have gained international recognition for their durability and distinctive patterns. Australian quarries yield unique varieties of limestone and sandstone in colors that mirror the continent’s dramatic landscape, from golden ochre to deep rust red.

Each regional stone variety brings its own characteristics in terms of durability, porosity, and aesthetic appeal, making them suitable for different applications from interior flooring to exterior cladding.

Carbon Footprint Benefits

Natural stone’s environmental benefits are particularly compelling when sourced locally, offering significant reductions in transportation-related carbon emissions. Unlike manufactured materials that require extensive processing and shipping, local stone can often be extracted and finished within a relatively small geographic radius. This proximity to project sites substantially decreases the carbon footprint associated with material transportation.

Studies have shown that using locally sourced stone can reduce transportation-related emissions by up to 80% compared to imported alternatives. For example, a typical project using stone from within 500 miles of the construction site generates approximately 2.7 fewer tons of CO2 emissions than one using imported stone from overseas.

Additionally, natural stone requires minimal processing compared to manufactured materials like concrete or ceramic tiles. The extraction and finishing processes consume less energy and produce fewer emissions than the manufacturing of synthetic alternatives. When combined with modern quarrying techniques and efficient cutting methods, local stone becomes an increasingly attractive option for environmentally conscious projects.

The durability of natural stone also contributes to its positive environmental impact, as its longevity reduces the need for replacement and subsequent material production over time.

Innovative Stone Processing Technologies

Water-Saving Processing Methods

The stone industry has made remarkable strides in water conservation through innovative processing technologies. Modern closed-loop water recycling systems now allow fabricators to reuse up to 98% of their process water, dramatically reducing consumption and environmental impact. These systems filter and treat water contaminated with stone particles, making it suitable for repeated use in cutting and polishing operations.

Advanced CNC machines equipped with water-efficient nozzles and precise spray control systems have revolutionized stone cutting. These machines use sophisticated software to optimize water usage based on the specific requirements of each cut, reducing waste while maintaining cutting quality. Some facilities have reported water savings of up to 60% compared to traditional methods.

Dry processing techniques are gaining traction for certain applications, particularly in finishing and edge work. These methods use specialized tools and dust collection systems instead of water-based cooling, further reducing water consumption. While not suitable for all processing steps, dry techniques can significantly decrease overall water usage when integrated into a comprehensive fabrication strategy.

Many fabricators are also implementing water quality monitoring systems that continuously assess pH levels, suspended solids, and other parameters. This real-time data allows for immediate adjustments to water treatment processes, ensuring optimal recycling efficiency while maintaining environmental compliance. These innovations not only conserve water but also reduce operating costs and support sustainable manufacturing practices.

Zero-Waste Initiatives

In response to growing environmental concerns, stone manufacturers are implementing innovative zero-waste initiatives that maximize the use of every extracted piece. Leading fabricators now employ digital templating and advanced cutting technologies to optimize slab utilization, reducing waste by up to 40% compared to traditional methods.

Remnants from larger projects are being repurposed into creative applications. Smaller pieces find new life as mosaic tiles, decorative inlays, and unique countertop features. Some manufacturers have developed crushing processes to transform stone waste into aggregate for concrete production or landscaping materials, ensuring nothing goes to waste.

Water recycling systems have become standard in modern fabrication facilities, with closed-loop systems filtering and reusing up to 98% of process water. This not only conserves resources but also prevents stone particles from entering local water systems.

Several companies have launched remnant marketplaces where designers and homeowners can purchase smaller pieces at reduced prices. These initiatives not only minimize waste but also make natural stone more accessible to budget-conscious consumers.

The industry is also exploring innovative binding technologies that combine stone waste with eco-friendly resins to create new surfacing materials. These composite products often match the durability of traditional stone while giving new purpose to what would otherwise be discarded material.

Thermal Mass Properties in Green Building

Natural stone’s inherent thermal mass properties make it an exceptional material for sustainable building design. Understanding stone’s thermal efficiency properties is crucial for architects and builders looking to create energy-efficient structures that maintain comfortable indoor temperatures year-round.

Thermal mass refers to a material’s ability to absorb, store, and gradually release heat. Dense natural stones like granite, limestone, and marble excel in this capacity, helping regulate indoor temperatures and reduce heating and cooling costs. During summer months, stone walls and flooring absorb excess heat during the day, keeping interiors cooler. At night, this stored heat slowly dissipates, creating a natural cooling cycle. In winter, the process works in reverse, with stone surfaces capturing and retaining warmth from heating systems or passive solar gain.

This natural temperature regulation can significantly decrease a building’s energy consumption. Studies have shown that structures incorporating substantial stone elements can reduce HVAC energy usage by 25-30% compared to conventional buildings. The effectiveness of stone’s thermal mass is particularly notable in climates with significant temperature fluctuations between day and night.

Modern green building designs often strategically position stone elements to maximize these benefits. South-facing stone walls can capture winter sun exposure, while stone flooring in sunlit areas serves as a natural heat sink. The thickness and type of stone can be carefully selected to optimize thermal performance based on local climate conditions and building requirements.

When combined with proper insulation and ventilation systems, stone’s thermal mass properties contribute to achieving higher energy efficiency ratings and LEED certification points. This makes natural stone an increasingly popular choice for sustainable architecture, offering both environmental benefits and long-term cost savings through reduced energy consumption.

Stone Recycling and Reuse

In recent years, the construction industry has witnessed a significant shift towards recycling natural stone, driven by both environmental consciousness and aesthetic appreciation for historical materials. This movement represents a perfect blend of sustainability and architectural heritage preservation.

Reclaimed stone from demolished buildings is increasingly finding new life in modern construction projects. These materials, often hundreds of years old, bring unique character and patina that new stone cannot replicate. Salvaged granite countertops, marble flooring, and limestone facades are being repurposed into stunning features in contemporary designs, reducing waste while adding distinctive charm to new spaces.

Adaptive reuse strategies have evolved to include innovative stone processing techniques. Damaged stone elements can now be cut and reformed into smaller pieces for applications like mosaic tiles, garden pathways, or decorative wall cladding. Even stone dust and fragments from processing are being incorporated into concrete mixtures and landscaping materials, ensuring minimal waste.

The economic benefits of stone recycling are equally compelling. Reclaimed materials often cost less than new stone while offering superior quality and durability. Historic buildings undergoing renovation particularly benefit from this trend, as matching aged stone with reclaimed materials ensures architectural authenticity.

Leading architects are now incorporating stone recycling requirements into their project specifications, creating a growing market for salvaged materials. This trend has sparked the emergence of specialized stone salvage yards and restoration experts who can assess, clean, and prepare reclaimed stone for new applications while maintaining its inherent character and structural integrity.

Certification and Standards

In today’s environmentally conscious market, adherence to sustainable stone certification standards has become crucial for industry credibility. Leading certification programs like ANSI/NSC 373 evaluate quarrying practices, water usage, and manufacturing processes to ensure environmental responsibility throughout the stone’s lifecycle.

The Natural Stone Council (NSC) has established comprehensive guidelines that address both environmental and social aspects of stone production. These standards cover everything from energy consumption and waste management to worker safety and community impact. Companies pursuing certification must demonstrate compliance through rigorous third-party audits.

LEED certification continues to drive sustainable stone practices, with natural stone contributing valuable points toward project certification. The material’s durability, local sourcing potential, and minimal processing requirements make it particularly attractive for green building initiatives.

Industry professionals should also be aware of ISO 14001 environmental management standards and the Chain of Custody certification, which tracks stone from quarry to final installation. These certifications ensure transparency and environmental responsibility throughout the supply chain.

When specifying stone products, look for certifications that verify both environmental stewardship and product quality. This includes regional standards that may apply to specific markets and international certifications that facilitate global trade while maintaining environmental integrity.

As we look to the future of construction, sustainable stone use stands at the forefront of architectural innovation. The industry’s shift toward environmentally conscious practices has positioned natural stone as a key material for green building initiatives. With advanced quarrying techniques, improved processing methods, and enhanced recycling capabilities, stone continues to demonstrate its vital role in sustainable construction.

The integration of digital technologies and smart manufacturing processes is making stone extraction and fabrication more efficient than ever, reducing waste and environmental impact. Architects and designers are increasingly combining traditional stone applications with modern sustainable practices, creating buildings that are both aesthetically pleasing and environmentally responsible.

Looking ahead, we can expect to see continued innovation in stone recycling, the development of more efficient processing methods, and greater integration of stone in green building certifications. The durability, longevity, and natural properties of stone make it an ideal choice for sustainable construction projects, ensuring its place in the future of environmentally conscious architecture.

As the construction industry continues to evolve, natural stone remains a testament to the possibility of combining traditional materials with modern sustainable practices, creating buildings that will stand the test of time while protecting our environment for future generations.