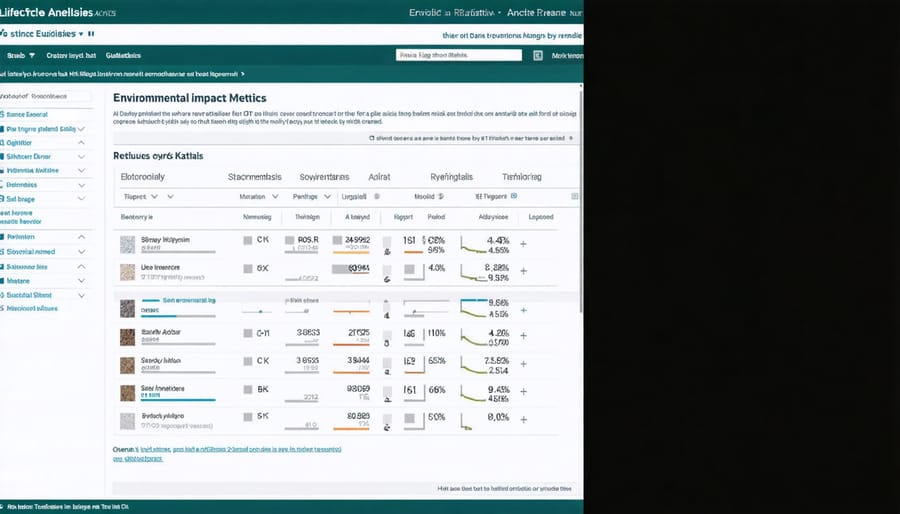

Lifecycle analysis software revolutionizes how we evaluate the environmental impact of natural stone materials, from quarry to installation. Modern LCA tools transform complex sustainability metrics into actionable insights, enabling architects and manufacturers to meet sustainable stone certification standards with precision and confidence.

By analyzing every phase of a stone product’s journey—extraction, processing, transportation, installation, and end-of-life disposal—these sophisticated platforms deliver comprehensive environmental impact assessments in real-time. Leading companies now leverage LCA software to optimize material selection, reduce carbon footprints, and demonstrate environmental stewardship to increasingly conscious consumers and regulatory bodies.

The integration of artificial intelligence and cloud computing has transformed traditional lifecycle assessment methods into dynamic decision-making tools. These advanced solutions not only track environmental metrics but also identify cost-saving opportunities and efficiency improvements throughout the natural stone supply chain, making sustainability both environmentally responsible and economically advantageous.

Understanding Lifecycle Analysis Software for Natural Stone

Key Features of Stone LCA Software

Modern stone LCA software comes equipped with several essential features designed to streamline the environmental impact assessment process for natural stone materials. At its core, these platforms offer robust calculation engines that analyze the complete lifecycle of stone products, from quarrying through installation and end-of-life considerations.

Material tracking capabilities allow users to monitor stone resources throughout their journey, documenting transportation distances, processing methods, and waste generation. This detailed tracking helps identify opportunities for optimization and waste reduction while maintaining accurate records for certification purposes.

The software’s reporting functionality generates comprehensive documentation that meets international standards, including Environmental Product Declarations (EPDs) and compliance reports. Users can create customizable dashboards displaying key metrics such as carbon footprint, water consumption, and energy usage in easy-to-understand formats.

Data management features enable the storage and organization of material specifications, supplier information, and processing parameters. This centralized database approach ensures consistency across projects and simplifies future assessments.

Most platforms include scenario modeling tools that allow users to compare different production methods, transportation routes, and end-of-life options. This capability helps stakeholders make informed decisions about sustainable practices and process improvements.

Integration capabilities with common design and building information modeling (BIM) software ensure seamless workflow incorporation. Real-time updates and cloud-based access enable collaboration among team members, while built-in verification tools help maintain data accuracy and reliability throughout the assessment process.

Data Collection and Input Requirements

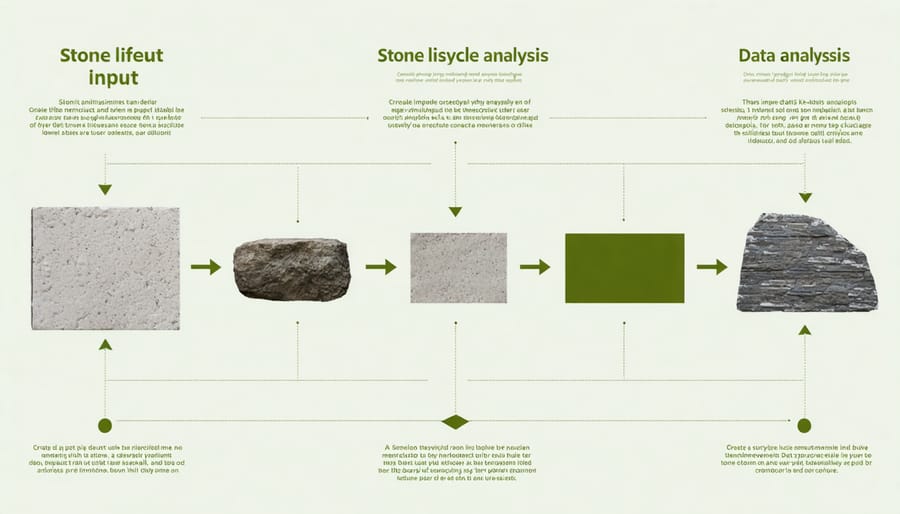

Accurate lifecycle analysis of stone materials requires comprehensive data collection across multiple parameters. The primary data inputs include raw material extraction information, such as quarrying energy consumption, water usage, and equipment emissions. Transportation details between various stages, including distances traveled and vehicle types used, are essential for calculating environmental impacts.

Processing data encompasses energy consumption during cutting, finishing, and fabrication, along with water usage and waste generation metrics. Chemical treatments, sealants, and other maintenance products must be documented with their respective environmental impacts and application frequencies.

Installation specifications need to detail anchoring systems, mortars, and additional materials used. For accurate analysis, the expected service life of the stone installation should be estimated, along with anticipated maintenance requirements and replacement schedules.

End-of-life considerations require data about demolition processes, potential for material reuse or recycling, and disposal methods. Regional factors, such as local energy grid composition and water availability, also influence the analysis results.

Quality assurance is crucial, and data should be verified through manufacturer documentation, industry standards, and field measurements when possible. Software users should maintain detailed records of data sources and assumptions to ensure transparency and reproducibility of the analysis results.

By gathering comprehensive data across these categories, professionals can conduct meaningful lifecycle assessments that accurately reflect the environmental impact of stone materials throughout their use cycle.

Popular LCA Software Solutions for Stone Industry

Comparison of Top Tools

Several leading lifecycle analysis software platforms stand out in the natural stone industry, each offering distinct advantages. SimaPro leads the market with its comprehensive database of stone materials and robust analysis capabilities. Its intuitive interface allows users to model complex natural stone supply chains, though its premium pricing starts at $8,000 annually.

GaBi offers specialized features for quarry operations and processing facilities, with detailed environmental impact assessments. While its learning curve is steeper, the software provides superior technical support and regular database updates. Annual licenses begin at $6,500.

OpenLCA presents a cost-effective alternative, offering free basic versions suitable for smaller projects. Its modular structure allows users to add specific natural stone databases as needed, though some advanced features require paid upgrades. The professional version costs $2,000 annually.

Tally, integrated with Revit, specifically caters to architects and designers working with natural stone. Its streamlined interface focuses on building materials and construction processes, making it ideal for project-specific assessments. Pricing starts at $695 per year.

One Click LCA emphasizes ease of use and offers specialized tools for construction materials, including natural stone. Its cloud-based platform enables team collaboration and includes regularly updated environmental product declarations (EPDs). Subscription costs range from $2,500 to $5,000 annually.

Key factors to consider when selecting software include database comprehensiveness for stone materials, integration capabilities with existing design tools, technical support quality, and pricing structure. Most platforms offer free trials, allowing users to evaluate their specific needs before committing.

Implementation and Best Practices

Setting Up Your First Analysis

Begin by gathering your project’s basic data, including material specifications, transportation details, and processing information for your natural stone materials. Launch your chosen LCA software and create a new project, giving it a clear, descriptive name.

Next, define your system boundaries – typically from quarry extraction to end-of-life disposal. Input your inventory data, starting with the extraction phase. Include energy consumption, water usage, and waste generation at each stage of the stone’s lifecycle.

Enter transportation details between processes, including distances and vehicle types. Document manufacturing processes, such as cutting, finishing, and polishing, with their associated resource consumption. Don’t forget to include installation parameters and anticipated maintenance requirements over the stone’s lifetime.

For accurate results, verify all data sources and cross-reference industry standards where possible. Run an initial analysis and review the results for any obvious errors or data gaps. Pay special attention to high-impact areas that might need additional scrutiny or data verification.

Finally, save your baseline analysis. This will serve as your reference point for future comparisons and optimization efforts.

Lifecycle analysis software plays a crucial role in making informed, sustainable decisions about natural stone materials. These powerful tools enable professionals to quantify environmental impacts, compare material options, and optimize their design choices for maximum sustainability. By providing detailed insights into the complete environmental footprint of stone products, from quarrying to end-of-life, LCA software empowers architects, designers, and manufacturers to create more environmentally responsible buildings and products while meeting both regulatory requirements and client expectations for sustainable construction practices.