Integrated Business Planning (IBP) revolutionizes stone supply chain management by connecting demand forecasting, inventory optimization, and production scheduling into a unified strategic framework. Leading stone manufacturers and suppliers leverage IBP to reduce stockouts by up to 40% while maintaining optimal inventory levels across their distribution networks. This sophisticated planning approach integrates real-time data from quarries, processing facilities, and customer demand patterns to create a responsive, agile supply chain that adapts to market fluctuations.

For project managers and contractors in the stone industry, IBP supply planning eliminates traditional bottlenecks by providing accurate material availability forecasts, streamlined procurement processes, and synchronized delivery schedules. The system’s predictive analytics capabilities enable companies to anticipate market demands, adjust production schedules proactively, and maintain consistent supply levels while minimizing carrying costs.

Recent industry data shows that stone companies implementing IBP systems achieve a 25-30% improvement in forecast accuracy and reduce lead times by up to 35%. This strategic approach transforms traditional stone supply chains into dynamic, data-driven operations that better serve both suppliers and end-users while maintaining competitive advantages in an increasingly demanding market.

Understanding IBP Supply Planning in Stone Projects

Key Components of IBP in Stone Supply Chain

Effective Integrated Business Planning (IBP) in stone project supply chains relies on several critical components working in harmony. First, demand forecasting must account for seasonal construction patterns, architectural trends, and regional market variations. This requires sophisticated data analytics tools that can process historical sales data alongside current market indicators.

Inventory optimization forms another crucial element, balancing storage costs with the need to maintain sufficient stock of popular stone varieties. This includes managing both raw blocks and processed materials while considering factors like quarry production schedules and processing lead times.

Supply network coordination represents the third key component, involving close collaboration between quarries, processors, transporters, and installers. Real-time communication systems and shared planning platforms enable stakeholders to synchronize their operations effectively.

Finally, risk management strategies must address challenges unique to the stone industry, such as weather-related disruptions, quarry capacity limitations, and quality variations. This includes maintaining alternative supplier relationships and developing contingency plans for common supply chain disruptions.

Benefits of Integrated Planning for Stone Projects

Integrated planning in stone projects delivers substantial benefits that enhance both operational efficiency and project outcomes. By synchronizing supply chain activities with project timelines, organizations can significantly reduce material waste and storage costs while ensuring timely delivery of specific stone types when needed.

This coordinated approach enables better inventory management, allowing companies to maintain optimal stock levels without overcommitting resources. Project managers can accurately forecast material requirements, leading to improved cash flow and reduced carrying costs. The system also facilitates better coordination between quarries, fabricators, and installation teams, minimizing delays and disruptions.

Quality control becomes more manageable through integrated planning, as materials can be inspected and processed at optimal points in the supply chain. This systematic approach helps identify potential issues early, reducing costly rework and project delays. Additionally, better planning enables more sustainable practices by optimizing transportation routes and reducing excess material orders.

For custom stone projects, integrated planning proves particularly valuable by ensuring specialized materials are sourced, fabricated, and delivered according to precise project specifications and timelines. This level of coordination results in smoother project execution and higher client satisfaction.

Implementing IBP Supply Planning for Stone Projects

Material Demand Forecasting

Material demand forecasting in stone projects requires a strategic blend of historical data analysis, market trends evaluation, and advanced predictive modeling. By analyzing past project requirements, seasonal patterns, and market fluctuations, suppliers can better anticipate future stone material needs.

The forecasting process begins with gathering historical consumption data across different stone types, including marble, granite, and limestone. This data is then combined with current market indicators such as construction trends, architectural preferences, and regional development plans to create baseline predictions.

Modern IBP systems employ sophisticated algorithms that consider multiple variables, including lead times, seasonal variations, and project timelines. These systems can adjust forecasts in real-time based on changes in demand patterns or unexpected market shifts, ensuring optimal inventory levels without excessive stockpiling.

Key factors in accurate stone material forecasting include:

– Project pipeline analysis

– Seasonal demand variations

– Regional construction activity

– Economic indicators

– Architectural trends

– Supply chain constraints

Successful forecasting also requires close collaboration between suppliers, contractors, and project managers. Regular communication helps identify potential demand spikes or changes in material preferences early, allowing for proactive inventory adjustments.

To enhance forecast accuracy, many organizations implement rolling forecasts that are updated monthly or quarterly, rather than relying solely on annual predictions. This approach provides greater flexibility and helps maintain optimal stock levels while minimizing waste and storage costs.

Inventory Management Strategies

Effective inventory management in stone supply planning requires a balanced approach between maintaining adequate stock levels and minimizing holding costs. The key lies in implementing a dynamic forecasting system that accounts for seasonal demand fluctuations and project-specific requirements.

First, establish minimum and maximum stock levels for each stone type based on historical demand data and lead times. This helps prevent both stockouts and excess inventory. Regular monitoring of stock turnover rates enables better decision-making for reorder points and quantities.

Implementing a ABC classification system proves valuable, where stones are categorized by their importance and value. Category A items (high-value, frequently used stones) require tighter control and more frequent monitoring than Category C items (lower-value, less frequently used materials).

Technology plays a crucial role through inventory management software that provides real-time visibility of stock levels, automated reordering, and demand forecasting. These systems should integrate with your broader IBP platform to ensure alignment with overall business objectives.

Consider implementing vendor-managed inventory (VMI) programs with reliable suppliers. This arrangement can reduce carrying costs while ensuring consistent availability of popular stone varieties. Additionally, maintain safety stock levels for critical items to buffer against supply chain disruptions or unexpected demand spikes.

Regular cycle counts and inventory audits help maintain accuracy and identify potential issues before they impact operations. Document storage conditions and handle materials properly to prevent damage and waste, which directly affects inventory costs and availability.

Supplier Collaboration Framework

Effective supplier collaboration is essential for successful IBP supply planning in stone projects. By establishing strong partnerships with stone suppliers, companies can ensure reliable material availability, consistent quality, and optimal pricing. This framework focuses on creating mutual value through transparent communication and shared objectives.

The foundation of supplier collaboration begins with a well-defined procurement process that emphasizes regular engagement and clear expectations. Key elements include establishing service level agreements (SLAs), implementing joint performance metrics, and maintaining open channels for feedback and improvement suggestions.

Regular supplier performance reviews help identify areas for optimization and strengthen relationships. These reviews should assess delivery reliability, quality consistency, price competitiveness, and responsiveness to change requests. Successful collaborations often involve shared technology platforms for real-time inventory visibility and demand forecasting.

Risk mitigation strategies should be developed jointly with suppliers, including contingency plans for supply disruptions and market fluctuations. Building long-term partnerships rather than transactional relationships enables better pricing negotiations, priority access to premium materials, and enhanced flexibility during peak demand periods.

Consider implementing supplier development programs to help key partners improve their capabilities and align with your quality standards. This investment in supplier relationships often yields significant returns through improved service levels and reduced supply chain disruptions.

Real-World Applications and Case Studies

Commercial Project Success Story

A leading commercial stone supplier successfully implemented IBP supply planning for a major retail development project in Chicago, resulting in a 30% reduction in inventory costs and improved delivery reliability. The project, spanning 18 months, involved coordinating multiple quarries across three continents to supply various stone materials for a 500,000-square-foot shopping complex.

The implementation team focused on three key areas: demand forecasting, inventory optimization, and supplier collaboration. By utilizing advanced analytics and real-time data tracking, they accurately predicted seasonal demand fluctuations and adjusted supply accordingly. This precision planning helped manage long-term project costs while maintaining quality standards.

The project’s success hinged on establishing a centralized planning hub that connected suppliers, fabricators, and installers through a cloud-based platform. This integration enabled real-time visibility of inventory levels, production schedules, and delivery status. When unexpected delays occurred at an Italian quarry, the system automatically redirected orders to alternative suppliers, preventing costly construction delays.

Key achievements included reducing storage costs by 25%, decreasing material waste by 15%, and maintaining a 98% on-time delivery rate throughout the project. The success of this implementation has since become a benchmark for large-scale commercial stone projects, demonstrating how effective IBP supply planning can transform traditional supply chain challenges into competitive advantages.

Residential Project Implementation

In residential stone projects, IBP supply planning plays a crucial role in ensuring smooth project execution and timely delivery. Consider the case of a high-end residential development in California, where multiple homes required custom limestone facades and marble interior features. The project team implemented IBP to coordinate deliveries across various quarries and fabricators.

The process began with detailed material forecasting, accounting for each home’s specific stone requirements and installation schedule. The team created a synchronized supply chain that connected quarries in Italy and Spain with local fabrication facilities and installation crews. Digital tracking systems monitored inventory levels and delivery status in real-time.

This implementation resulted in a 30% reduction in material storage costs and eliminated installation delays caused by supply issues. The system also allowed for quick adjustments when design changes occurred, preventing costly delays and material waste.

Key success factors included:

– Regular communication between suppliers, fabricators, and installers

– Buffer stock maintenance for commonly used materials

– Weather-dependent delivery scheduling

– Quality control integration at each supply chain stage

The project demonstrated how IBP can transform residential stone installations from potentially challenging logistics operations into streamlined, efficient processes. By maintaining precise inventory control and coordinating multiple suppliers, the team delivered all stone elements on schedule while maintaining optimal stock levels throughout the project duration.

Technology Integration and Tools

Effective IBP supply planning in the stone industry relies heavily on advanced technological solutions that streamline processes and enhance decision-making. Today’s modern stone design tools integrate seamlessly with supply planning platforms, creating a comprehensive ecosystem for project management.

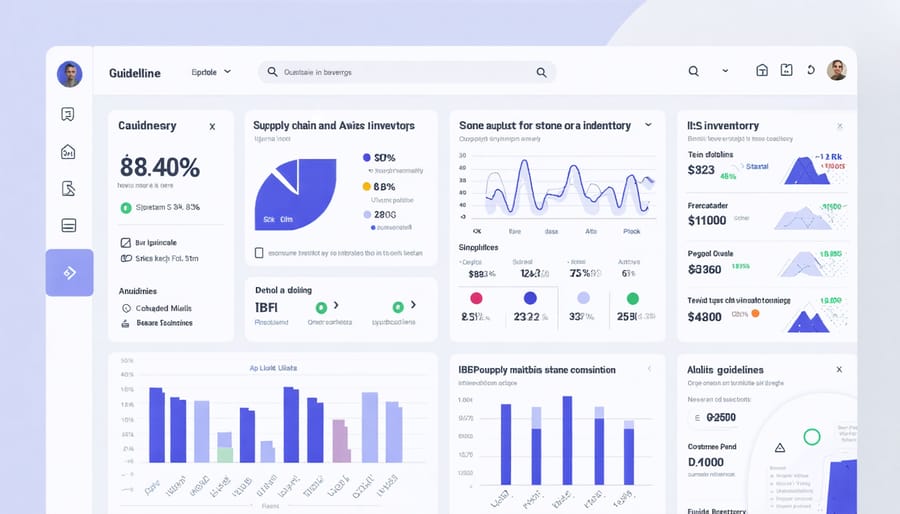

Cloud-based IBP solutions offer real-time visibility into inventory levels, supplier capabilities, and market demands. These platforms typically feature interactive dashboards that display key performance indicators (KPIs), enabling quick assessment of supply chain health and potential bottlenecks. Advanced analytics capabilities help predict material requirements, optimize stock levels, and forecast seasonal demand patterns specific to stone products.

Digital twin technology is increasingly being adopted to create virtual representations of supply chains, allowing planners to simulate various scenarios and assess their impact before implementation. This capability is particularly valuable when dealing with natural stone varieties that have varying lead times and availability.

Enterprise Resource Planning (ERP) systems form the backbone of IBP technology integration, connecting various departments and stakeholders. These systems typically include:

– Material Requirements Planning (MRP) modules

– Supplier relationship management tools

– Inventory optimization algorithms

– Transportation management systems

– Quality control tracking features

Mobile applications enable field teams to update inventory data, track shipments, and communicate with suppliers in real-time. Artificial Intelligence and Machine Learning algorithms analyze historical data to improve forecast accuracy and suggest optimal order quantities, while automated alerts help prevent stockouts and overstock situations.

Integration with supplier portals allows for seamless communication and order processing, reducing lead times and improving accuracy. These technological solutions are continuously evolving, with new features being added to address specific challenges in natural stone supply planning and inventory management.

Integrated Business Planning (IBP) supply planning has emerged as a crucial framework for optimizing stone industry operations, offering significant benefits in inventory management, cost reduction, and customer satisfaction. As we’ve explored throughout this article, successful implementation requires a careful balance of technology, process alignment, and stakeholder collaboration.

The future of IBP supply planning in the stone industry looks promising, with emerging technologies like AI and machine learning enhancing forecasting accuracy and decision-making capabilities. Companies that embrace these innovations while maintaining strong foundational practices will be better positioned to navigate market uncertainties and meet evolving customer demands.

Key takeaways include the importance of real-time data integration, cross-functional collaboration, and continuous process improvement. Organizations must focus on developing robust communication channels, investing in appropriate technology solutions, and maintaining flexibility in their planning approaches to achieve optimal results.

Looking ahead, sustainability considerations and digital transformation will likely play increasingly important roles in IBP supply planning. Companies should prepare for these shifts by building adaptable systems and incorporating environmental factors into their planning processes.

Remember that successful IBP implementation is an ongoing journey rather than a destination. Regular assessment, adjustment, and optimization of your supply planning strategies will ensure continued effectiveness and competitive advantage in the dynamic stone industry landscape.