When it comes to kitchen durability, few decisions impact your daily life more than choosing the right countertop material. Modern engineered quartz leads the pack in durability ratings, consistently outperforming traditional materials with its 7/10 Mohs hardness score and near-indestructible resistance to scratches, stains, and impacts. While natural granite has long been the gold standard for luxury kitchens, laboratory testing reveals that properly sealed quartz surfaces withstand up to 25% more direct force without chipping or cracking.

Yet durability isn’t just about hardness – it’s about maintaining beauty through years of real-world use. The latest generation of porcelain surfaces offers remarkable resilience against heat damage, handling temperatures up to 1,000°F without scorching. Meanwhile, ultra-compact surfaces like Dekton have revolutionized what’s possible in kitchen durability, combining the best properties of glass, porcelain, and quartz into a virtually indestructible surface that laughs off knife marks and chemical exposure.

For homeowners seeking the perfect balance of durability and functionality, understanding these material innovations isn’t just about avoiding damage – it’s about investing in a surface that will maintain its pristine appearance through decades of family memories and culinary adventures.

Top Contenders for Most Durable Countertop Materials

Engineered Quartz

Engineered quartz has emerged as a leading contender in the durability race for kitchen countertops. Understanding the pros and cons of quartz countertops is essential for making an informed decision. Composed of approximately 93% natural quartz crystals combined with polymer resins and pigments, this engineered stone offers exceptional durability that often surpasses natural stone options.

The manufacturing process creates a non-porous surface that resists scratches, stains, and bacterial growth. Unlike natural stone, engineered quartz doesn’t require sealing and maintains its durability without regular maintenance treatments. The material scores a remarkable 7 out of 10 on the Mohs hardness scale, making it highly resistant to everyday wear and tear.

Heat resistance is another notable feature, though it’s recommended to use trivets for extremely hot pots and pans to prevent potential thermal shock. The uniform composition of engineered quartz eliminates weak points often found in natural stones, resulting in superior impact resistance and structural integrity throughout the entire surface.

In daily kitchen use, quartz stands up exceptionally well to common challenges like coffee spills, wine stains, and acidic foods. The material’s resistance to scratching makes it ideal for busy kitchens where cutting and food preparation are frequent activities. While no countertop material is completely indestructible, engineered quartz comes remarkably close, offering a perfect balance of durability and practical functionality.

Modern manufacturing techniques have also improved the material’s aesthetic appeal, with options ranging from solid colors to patterns that convincingly mimic natural stone, all while maintaining its superior durability characteristics.

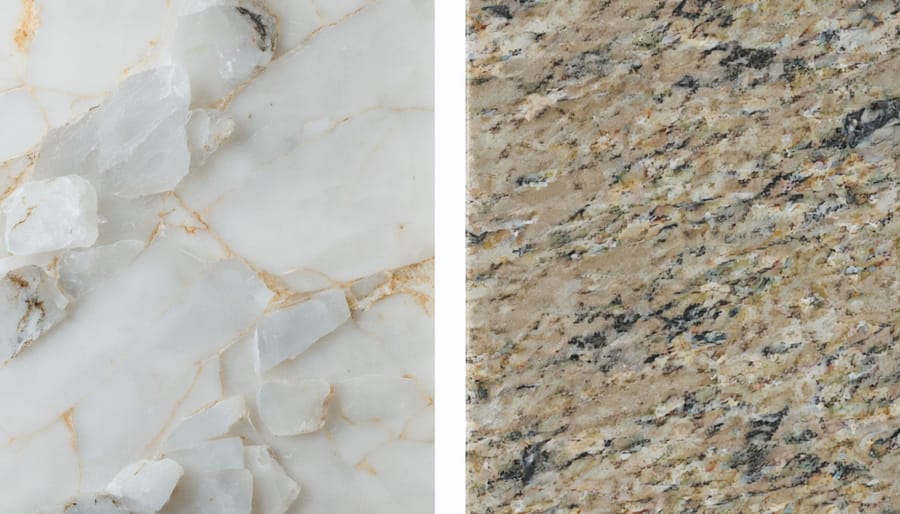

Natural Granite

Natural granite remains a top contender in the durability race, contributing significantly to granite’s enduring popularity in modern kitchens. This igneous rock, formed under intense heat and pressure, boasts a Mohs hardness rating of 6-7, making it highly resistant to scratches and daily wear.

One of granite’s strongest attributes is its heat resistance, capable of withstanding temperatures up to 480°F (250°C) without damage. This natural stone won’t scorch or discolor when exposed to hot pots and pans, providing peace of mind during busy meal preparations.

While granite isn’t completely indestructible, its durability is impressive when properly maintained. The stone’s crystalline structure creates a dense, non-porous surface when sealed, effectively resisting stains and bacteria growth. A quality sealer application every 1-2 years maintains this protection, ensuring the countertop’s longevity.

Impact resistance is another notable characteristic of granite. Though it can chip if struck with heavy objects at sharp angles, these instances are relatively rare with normal kitchen use. The stone’s natural composition also provides excellent scratch resistance against knife blades and typical kitchen tools.

Color stability adds to granite’s durability profile. Unlike some engineered materials, granite maintains its original appearance for decades when properly maintained, resisting fading even in areas exposed to direct sunlight. Each slab’s unique mineral composition creates natural variation in pattern and color, helping to camouflage minor wear patterns that might develop over time.

Other Durable Options

While granite and quartz often dominate discussions about durable countertops, several other materials offer exceptional durability worth considering. Quartzite, a natural metamorphic rock, stands out for its remarkable hardness, scoring higher on the Mohs scale than both granite and quartz. This material resists scratching, heat damage, and etching, making it an excellent choice for busy kitchens.

Porcelain has emerged as another highly durable option, particularly with the advent of large-format porcelain slabs. These surfaces resist scratching, staining, and UV damage while handling extreme temperatures without issue. Modern porcelain countertops can even mimic the appearance of natural stone or concrete while offering superior durability.

Sintered stone, a relative newcomer to the market, combines raw mineral materials under extreme heat and pressure to create an incredibly resilient surface. This engineered material resists scratches, heat, and UV radiation while remaining completely non-porous.

Ultra-compact surfaces like Dekton offer similar benefits, created through a sophisticated manufacturing process that results in exceptional durability. These materials can withstand direct heat, resist scratching, and maintain their appearance even with heavy use.

Each of these alternatives brings unique advantages to kitchen applications, though availability and cost may influence their practicality for specific projects.

Durability Factors to Consider

Heat Resistance

When it comes to heat resistance, engineered quartz and granite are top performers, withstanding temperatures up to 300°F without damage. Natural quartzite surpasses both, maintaining its integrity even at higher temperatures. Stainless steel countertops, commonly used in professional kitchens, excel at heat resistance but can show discoloration from extreme temperatures.

While ceramic and porcelain surfaces also offer excellent heat resistance, marble and soapstone require more caution. Direct heat can cause thermal shock in marble, potentially leading to cracks or discoloration. Butcher block and laminate countertops are the most vulnerable to heat damage, requiring immediate use of trivets and hot pads to prevent scorching, burns, or separation of materials.

For optimal protection regardless of material choice, using trivets and hot pads is recommended as a best practice for maintaining countertop appearance and integrity long-term.

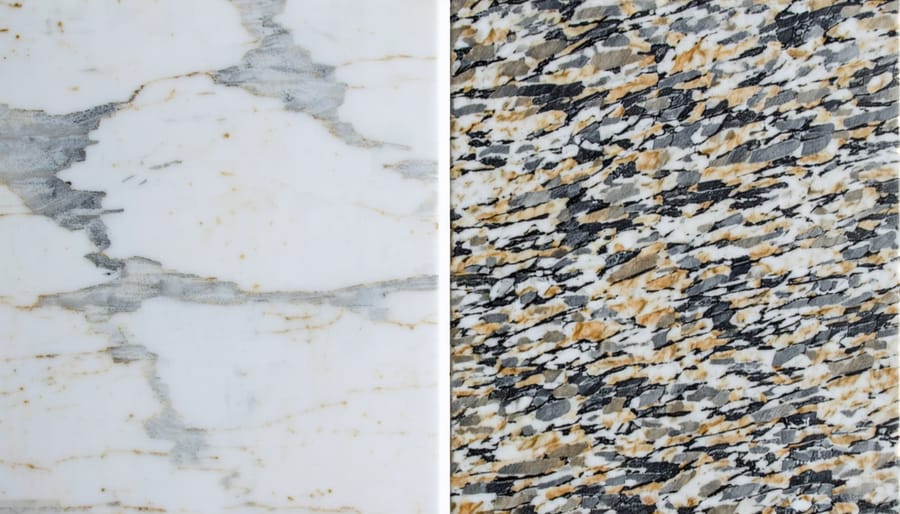

Scratch and Impact Resistance

When it comes to scratch and impact resistance, quartz consistently ranks at the top among countertop materials. Its engineered composition, combining natural quartz with resins, creates a surface that’s highly resistant to scratches from everyday kitchen activities. While no material is completely scratch-proof, quartz can withstand regular knife work and heavy pot impacts without showing significant wear.

Granite follows closely behind, offering excellent scratch resistance due to its natural hardness rating of 6-7 on the Mohs scale. However, it can chip under severe impact, particularly around edges and corners. Stainless steel, though dent-prone, shows remarkable resistance to scratches and won’t crack under impact. Concrete performs well against impacts but may show scratches over time unless properly sealed.

Lesser-performing materials include marble, which scratches easily, and butcher block, which readily shows knife marks and dents from regular use.

Stain Resistance

When it comes to stain resistance, engineered quartz and natural stone materials lead the pack. Quartz, being non-porous, offers superior protection against stains from common kitchen items like wine, coffee, and oils. While the stain resistance of granite is also impressive when properly sealed, it requires periodic maintenance to maintain its protective barrier. Stainless steel and solid surface materials like Corian also perform well against stains, though acidic substances may cause discoloration over time. Butcher block and concrete countertops are more susceptible to staining and require immediate cleanup of spills and regular sealing to prevent permanent marks. For optimal stain protection, quartz remains the top choice, offering peace of mind without the need for frequent sealing or special cleaning protocols.

Chemical Resistance

When it comes to chemical resistance, engineered quartz and granite lead the pack among kitchen countertop materials. Quartz surfaces withstand exposure to common household cleaners, acids like lemon juice and vinegar, and even harsh chemicals without etching or staining. Granite also performs exceptionally well against most chemicals, though acidic substances may require prompt cleaning to prevent dulling.

Stainless steel offers superior resistance to chemicals and acids, making it a favorite in professional kitchens. However, both marble and limestone are vulnerable to acidic substances, which can cause etching and surface damage. Solid surface materials like Corian maintain good chemical resistance but may show wear from harsh abrasives or strong chemicals over time.

For optimal protection, regardless of material choice, always use cutting boards and clean spills promptly, especially from acidic foods and beverages.

Real-World Performance and Maintenance Requirements

In real-world kitchen environments, durability varies significantly based on usage patterns and maintenance practices. Granite consistently demonstrates exceptional resilience, withstanding daily wear while maintaining its appearance with proper sealing every 1-2 years. Restaurant kitchens using granite countertops report minimal wear even after a decade of heavy use.

Quartz has emerged as a top performer in both residential and commercial settings, with manufacturers reporting fewer warranty claims compared to other materials. Maintaining quartz countertops requires only routine cleaning with mild soap and water, making it particularly appealing for busy households.

Concrete countertops, while durable, show their age through natural patina development and may require periodic resealing to prevent staining. Field studies indicate that properly sealed concrete can maintain its integrity for 15-20 years under normal use conditions.

Stainless steel, common in professional kitchens, demonstrates excellent heat resistance and sanitation properties but tends to show scratches and dents over time. Users report that these marks become part of the material’s character rather than diminishing its functionality.

Butcher block requires the most frequent maintenance, needing monthly oiling to prevent drying and cracking. However, its unique advantage lies in the ability to sand and refinish the surface completely, essentially creating a new countertop.

Regular maintenance requirements vary by material:

– Granite: Seal annually, clean daily with stone cleaner

– Quartz: Daily cleaning only, no sealing required

– Concrete: Reseal every 1-3 years, clean with pH-neutral products

– Stainless Steel: Daily cleaning, occasional polishing

– Butcher Block: Monthly oiling, immediate attention to spills

Real-world performance data suggests that materials requiring minimal maintenance, such as quartz and granite, tend to maintain their appearance and functionality longer in typical household settings.

When it comes to durability in kitchen countertops, quartz consistently ranks as the top performer, combining exceptional hardness with practical maintenance requirements. While granite and quartzite also offer excellent durability, quartz’s engineered nature gives it a slight edge in resistance to scratches, stains, and impact. However, the best choice ultimately depends on your specific needs and lifestyle. If you prioritize natural beauty alongside durability, quartzite presents an excellent alternative. For those seeking the absolute toughest option with minimal maintenance, quartz remains the gold standard. Remember that proper sealing and maintenance of any countertop material will significantly extend its lifespan and preserve its appearance. Consider factors like cost, aesthetic preferences, and maintenance requirements alongside durability when making your final decision.