At the intersection of ancient craftsmanship and cutting-edge technology, advanced architectural stone is revolutionizing how we design and construct our most ambitious buildings. Through parametric design fundamentals, modern architects are pushing the boundaries of what’s possible with natural stone, creating structures that were unimaginable just decades ago.

Today’s architectural stone applications combine computational design, robotic fabrication, and sophisticated material science to transform solid rock into fluid, organic forms. From ultra-thin stone veneers reinforced with carbon fiber to precisely-carved geometric facades that optimize thermal performance, this reimagining of one of humanity’s oldest building materials is opening new frontiers in sustainable architecture.

Leading firms worldwide are leveraging these innovations to create landmarks that honor stone’s timeless beauty while embracing its untapped potential. The result is a new architectural language that speaks to both our heritage and our future – one where traditional limestone, granite, and marble perform in ways their ancient quarriers could never have imagined.

As we stand at this technological crossroads, advanced architectural stone isn’t just changing how we build – it’s fundamentally altering our understanding of what stone can achieve in the modern world.

What Makes Stone Architecture ‘Advanced’?

Digital Design Integration

Modern parametric design software has revolutionized how architects and designers approach stone architecture. These sophisticated digital tools enable the creation of complex geometric patterns and intricate structural forms that were previously impossible or impractical to achieve with traditional methods.

Using advanced 3D modeling and computational design, architects can now visualize and test various stone configurations before construction begins. The software analyzes structural integrity, material efficiency, and installation requirements, ensuring optimal use of natural stone while reducing waste and costs.

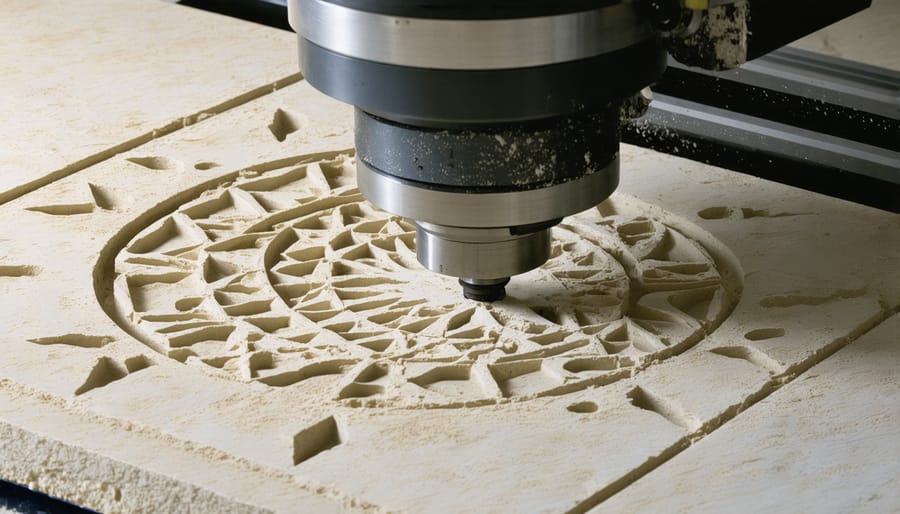

Digital fabrication technologies seamlessly integrate with these design tools, allowing for precise cutting and shaping of stone elements. CNC machines and robotic fabrication systems can translate complex digital designs into physical reality with unprecedented accuracy, maintaining tight tolerances and ensuring perfect fit during installation.

This digital integration extends beyond design to project management, where Building Information Modeling (BIM) coordinates stone specifications, installation sequences, and maintenance requirements. The result is a more streamlined process from concept to completion, enabling architects to push the boundaries of stone architecture while maintaining practical feasibility and structural integrity.

Modern Fabrication Methods

Today’s architectural stone industry relies heavily on advanced manufacturing technologies that combine precision with efficiency. CNC stone fabrication has revolutionized the way we shape and cut stone materials, enabling complex geometric patterns and intricate designs that were once impossible to achieve through traditional methods.

Computer-controlled machines equipped with diamond-tipped tools can now cut, polish, and shape stone with millimeter-precise accuracy. These systems interpret digital designs directly from CAD software, ensuring perfect replication of architectural specifications. Water jet cutting technology offers another sophisticated approach, using high-pressure water mixed with abrasive particles to cut through even the hardest stone materials with remarkable precision.

Modern fabrication facilities also employ robotic arms and automated systems for material handling and finishing processes. These technologies not only increase production efficiency but also improve worker safety and reduce material waste. 3D scanning capabilities allow fabricators to create exact digital models of existing structures, ensuring perfect fit and alignment of new stone elements with historical or existing architectural features.

Parametric Design’s Impact on Stone Applications

Complex Geometries

Modern technology and parametric design have revolutionized what’s possible with architectural stone, enabling the creation of complex geometric patterns and structures that were previously unimaginable. Through advanced computational design and CNC machining, stone can now be carved into intricate lattices, flowing curves, and mathematically precise patterns that push the boundaries of traditional stonework.

Notable examples include the flowing stone facade of the Sheikh Zayed Bridge in Abu Dhabi, where limestone panels create a rippling effect that seems to defy gravity. The Lotus Temple in New Delhi showcases how marble can be precisely cut and assembled to form complex petal-like structures that appear both delicate and monumental.

These sophisticated designs are achieved through a combination of 3D modeling software and robotic fabrication techniques. Architects can now experiment with various geometric patterns, testing their structural integrity and visual impact before a single piece of stone is cut. This process allows for the creation of self-supporting stone structures, intricate wall textures, and complex architectural elements that maintain the material’s natural beauty while incorporating contemporary design principles.

The ability to create these complex geometries has opened new possibilities for sustainable architecture, as precisely engineered stone elements can contribute to natural ventilation, light diffusion, and thermal regulation while serving as striking architectural features.

Optimization and Efficiency

Parametric design has revolutionized how we approach architectural stone, bringing unprecedented levels of optimization and efficiency to both design and construction processes. Through advanced computational modeling, architects can now analyze and optimize stone elements for maximum structural performance while minimizing material waste – a crucial aspect of modern sustainable building practices.

This technology enables designers to precisely calculate the optimal thickness, size, and placement of stone components based on structural loads and aesthetic requirements. By simulating various configurations, parametric design tools can identify the most efficient use of materials, potentially reducing stone waste by 20-30% compared to traditional methods.

The efficiency extends beyond material usage to the manufacturing process itself. Computer-aided manufacturing (CAM) systems, guided by parametric models, can precisely cut and shape stone pieces with minimal deviation from specifications. This precision not only reduces waste but also ensures faster assembly on-site, as pieces fit together exactly as designed.

Moreover, parametric optimization allows for better load distribution and structural efficiency. By analyzing stress patterns and material properties, designers can create lighter yet stronger stone structures. This approach has enabled the development of innovative stone facades and load-bearing elements that use less material while maintaining structural integrity and architectural beauty.

Real-World Applications

Contemporary Facades

Today’s contemporary building facades showcase the remarkable evolution of architectural stone through parametric design. The Broad Museum in Los Angeles exemplifies this advancement with its distinctive “veil” structure, featuring precision-cut stone panels that create a honeycomb-like exterior. Similarly, the Harbin Opera House in China demonstrates how curved stone elements can flow seamlessly across complex geometries, challenging traditional notions of stone construction.

Recent innovations include the Stone Tower in Copenhagen, where algorithmically optimized stone blocks interlock to form a self-supporting structure. Each piece is uniquely cut using advanced CNC technology, maximizing material efficiency while creating stunning visual effects. The Qatar National Library features a facade where traditional limestone meets modern engineering, with parametrically designed perforations that control natural light and thermal performance.

These projects demonstrate how computational design and digital fabrication have transformed stone from a conventional building material into a medium for architectural innovation. By combining age-old materials with cutting-edge technology, architects are creating facades that are not only visually striking but also more sustainable and efficient than their traditional counterparts.

Interior Applications

Modern interior design has embraced parametric stone elements to create stunning architectural features that blend traditional materials with contemporary aesthetics. These innovative applications transform ordinary spaces into extraordinary environments through carefully calculated geometric patterns and precision-cut stone components.

Curved feature walls showcase the versatility of advanced stone fabrication, where individual pieces flow seamlessly together to create fluid, organic surfaces. Dramatic stone staircases with floating treads demonstrate both the structural capabilities and visual lightness achievable through parametric design. Custom-cut ceiling panels and room dividers utilize sophisticated patterns that play with light and shadow, adding depth and visual interest to interior spaces.

In luxury environments, parametric stone installations often serve as focal points, such as reception desks with complex geometries or sculptural columns that appear to defy conventional stone properties. These elements can be integrated with lighting systems to enhance their dramatic impact and create dynamic atmospheric effects.

Practical applications include modular wall systems that combine natural stone with other materials, allowing for easy installation and future modifications. Kitchen and bathroom surfaces benefit from parametric design through seamless integration of sinks, drainage systems, and functional elements within single stone pieces.

The precision of modern fabrication methods ensures exact fitting of complex stone elements while minimizing material waste, making these sophisticated designs both aesthetically pleasing and environmentally conscious.

Future Possibilities

The future of advanced architectural stone holds exciting possibilities as technology continues to evolve. Digital fabrication and parametric design are pushing the boundaries of what’s possible with stone construction, leading to increasingly complex and efficient designs. Emerging trends suggest that we’ll see more integration of smart technologies within stone structures, including self-healing materials and embedded sensors for structural monitoring.

3D printing with stone-based materials is gaining traction, offering the potential for creating intricate geometric forms while reducing waste and labor costs. Research is underway to develop composite materials that combine stone’s natural beauty with enhanced structural properties, potentially leading to stronger, lighter, and more versatile building materials.

Sustainable practices are driving innovation in stone recycling and processing. New techniques for stone extraction and fabrication are being developed to minimize environmental impact while maximizing material efficiency. The industry is also exploring ways to incorporate waste stone products into new architectural elements, creating a more circular economy.

Climate-responsive stone architecture is another emerging trend, with designers developing systems that use stone’s thermal mass properties more effectively. Advanced computer modeling is enabling architects to optimize stone placement for natural cooling and heating, reducing building energy consumption.

Looking ahead, we can expect to see increased collaboration between traditional stonework and robotic fabrication, allowing for more precise and complex stone installations. The integration of augmented reality in stone construction will likely streamline installation processes and enable more accurate visualization of finished projects before construction begins. These developments promise to maintain stone’s relevance in architecture while expanding its applications in exciting new directions.

The convergence of traditional stone craftsmanship with parametric design has ushered in a new era of architectural possibilities. Through advanced computational tools and digital fabrication methods, stone architecture has evolved from conventional geometric forms to complex, organic structures that were previously unimaginable. This transformation enables architects and designers to push the boundaries of what’s possible with natural stone while maintaining its timeless appeal and sustainable qualities.

The integration of parametric design has not only revolutionized the aesthetic potential of stone but has also optimized its structural performance and material efficiency. Modern projects now showcase intricate patterns, seamless transitions, and innovative load-bearing solutions that maximize stone’s natural properties while minimizing waste. This technological advancement has made it possible to create more ambitious architectural features while reducing costs and environmental impact.

As we look to the future, the combination of traditional stone craftsmanship and digital innovation continues to evolve. This synthesis promises even more extraordinary architectural achievements, ensuring that natural stone remains a relevant and vital material in contemporary design. The marriage of ancient material wisdom with cutting-edge technology demonstrates that architectural stone is not just preserving its heritage but actively shaping the future of sustainable construction.