Revolutionizing modern design and manufacturing, generative design programs harness artificial intelligence to explore thousands of potential solutions in minutes – a task that would take human designers months to accomplish. By combining advanced parametric design in architecture with machine learning algorithms, these powerful tools are transforming how we approach everything from structural engineering to artistic expression in stone fabrication.

Unlike traditional CAD software, generative design platforms analyze project requirements, material constraints, and performance goals to automatically produce optimized design alternatives. For architects and stone industry professionals, this means the ability to rapidly explore innovative forms while ensuring structural integrity, minimizing material waste, and reducing production costs. The technology’s ability to balance complex variables – from load-bearing requirements to aesthetic preferences – is opening new possibilities in architectural stone applications that were previously impossible to achieve through conventional methods.

Through cloud computing and increasingly sophisticated algorithms, these programs are becoming more accessible and practical for businesses of all sizes, democratizing access to advanced design optimization that was once limited to large corporations and research institutions.

What Makes Generative Design Different in Stone Fabrication

Traditional vs. Algorithmic Stone Design

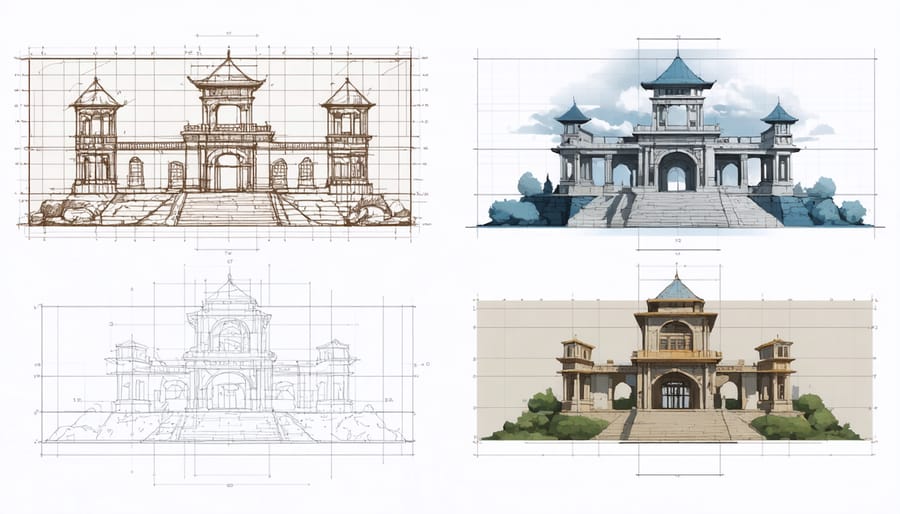

Traditional stone design relied heavily on manual measurements, hand sketches, and craftsmanship passed down through generations. Artisans would spend countless hours measuring spaces, creating templates, and carefully planning cuts to maximize material usage. While this approach produced beautiful results, it was time-consuming and left room for human error.

Modern AI-powered stone mapping and algorithmic design have revolutionized this process. Today’s digital tools can analyze stone slabs instantly, identifying optimal cutting patterns, natural veining directions, and potential defects. These programs consider multiple variables simultaneously, including material waste reduction, structural integrity, and aesthetic continuity.

The algorithmic approach doesn’t replace human creativity but enhances it. Designers can explore countless variations within minutes, visualize outcomes before cutting begins, and make informed decisions about material usage. This marriage of traditional craftsmanship with computational power has led to more efficient production, reduced waste, and the ability to tackle increasingly complex design challenges while maintaining the natural beauty of stone materials.

Key Benefits of Computer-Generated Stone Designs

Computer-generated stone designs revolutionize the traditional approach to stone fabrication and installation by offering several compelling advantages. First, these programs dramatically increase efficiency by automating complex calculations and pattern generation, reducing design time from days to hours. This acceleration allows professionals to take on more projects while maintaining high quality standards.

The creative possibilities expand exponentially with generative design tools. These programs can produce countless variations of patterns and layouts, helping designers discover unique solutions that might not be apparent through conventional methods. They can also quickly adapt designs to specific space constraints or material requirements, ensuring optimal use of stone resources.

Cost reduction is another significant benefit, as these programs minimize material waste through precise calculations and efficient layout planning. By simulating different design options virtually, professionals can identify potential issues before cutting begins, preventing costly mistakes during fabrication.

Additionally, these tools enhance collaboration between designers, fabricators, and clients by providing detailed visualizations and technical specifications. This improved communication leads to better project outcomes and higher client satisfaction. The ability to generate accurate material estimates and installation guidelines also helps in proper project planning and execution.

Popular Generative Design Software for Stone Work

Industry-Standard Programs

Several well-established software solutions dominate the generative design landscape, each offering unique capabilities for stone fabrication and architectural design. Autodesk’s Fusion 360 stands out as a comprehensive platform, combining generative design with traditional CAD functionality. Its intuitive interface allows users to input design parameters and constraints specific to stone materials, generating multiple viable solutions that optimize for structural integrity and material efficiency.

Grasshopper, a visual programming interface that works within Rhinoceros 3D, has become an industry favorite for its flexibility and powerful algorithmic modeling capabilities. It excels in creating complex geometric patterns often seen in contemporary stone architecture, while maintaining manufacturability.

For specialized stone applications, StoneCAD and AlphaCAM offer purpose-built solutions that incorporate generative design principles with stone-specific fabrication requirements. These programs understand the unique properties of natural stone and automatically account for factors like grain direction, structural limitations, and cutting optimization.

Solidworks’ generative design tools have also gained traction in the stone industry, particularly for projects requiring integrated mechanical systems or complex assemblies. The software’s ability to optimize material usage while maintaining structural requirements has made it valuable for sustainable design practices.

These industry-standard programs typically offer cloud computing capabilities, allowing for rapid iteration and testing of multiple design variations, essential for modern stone fabrication workflows.

Emerging Technology Platforms

Several innovative platforms are reshaping the landscape of generative design in the stone industry. Grasshopper, a visual programming language integrated with Rhino 3D, has emerged as a powerful tool for creating advanced stone design techniques. Its node-based interface allows designers to create complex geometric patterns while considering material properties and fabrication constraints.

Autodesk’s Project Refinery has introduced AI-driven optimization capabilities specifically tailored for architectural applications. This platform analyzes thousands of design variations to identify optimal solutions for stone placement, structural integrity, and material efficiency.

Dynamo Studio, another emerging platform, offers unique capabilities for stone fabricators by combining visual programming with BIM workflows. Its integration with Revit makes it particularly valuable for projects requiring detailed coordination between design and fabrication phases.

CloudCUT, a cloud-based solution, has revolutionized stone cutting optimization by utilizing machine learning algorithms to minimize waste and maximize material usage. This platform can process complex designs while considering factors like veining patterns and material strength.

These new platforms share common features like cloud computing capabilities, real-time collaboration tools, and advanced visualization options. They represent a significant evolution from traditional CAD software, offering more sophisticated approaches to stone design and fabrication while maintaining user-friendly interfaces.

Real-World Applications and Success Stories

Residential Projects Showcase

Generative design is revolutionizing residential architecture, creating homes that are both aesthetically striking and functionally optimized. The Thompson Residence in Seattle showcases how algorithmic design transformed a challenging hillside plot into a harmonious living space. The program analyzed topographical data and solar patterns to create a terraced structure that maximizes natural light while minimizing excavation costs.

In Barcelona, the Casa Organica project demonstrates how generative design can incorporate biophilic elements. The algorithm generated unique ceiling patterns that mirror natural growth patterns, with integrated skylights positioned to track the sun’s movement throughout the day. The home’s interior walls feature parametrically designed stone panels that optimize acoustic performance while creating visual interest.

The Meadowbrook Development in Austin, Texas, utilized generative design to create custom facade elements for 12 single-family homes. Each residence features uniquely patterned stone screens that provide privacy and shade while maintaining visual cohesion throughout the neighborhood. The program considered factors like wind patterns, sun exposure, and viewing angles to optimize each screen’s design.

For smaller-scale applications, homeowners are using generative design to create custom interior features. The Wilson residence in Portland showcases a generatively designed staircase that doubles as a sculptural centerpiece. The algorithm balanced structural requirements with aesthetic preferences, resulting in a flowing design that appears to defy gravity while meeting all safety codes.

These residential projects demonstrate how generative design can address complex architectural challenges while creating spaces that feel both personal and innovative. The technology enables architects to explore countless design iterations quickly, leading to solutions that might not have been discovered through traditional design methods.

Commercial Success Stories

Generative design has made significant strides in commercial applications, with several industry leaders demonstrating its transformative potential. Autodesk and NASA collaborated on redesigning a spacecraft partition that achieved a 35% weight reduction while maintaining structural integrity – a breakthrough that showcased the technology’s capability in aerospace engineering.

In architecture, Zaha Hadid Architects employed generative design for the Morpheus Hotel in Macau, creating a striking exoskeleton structure that optimized both form and function. The program analyzed thousands of possible configurations to deliver a design that maximized structural efficiency while creating the building’s distinctive aesthetic.

The automotive industry has also embraced this technology, with General Motors utilizing generative design to reimagine vehicle components. Their collaboration with Autodesk resulted in a seat bracket that was 40% lighter and 20% stronger than its conventional counterpart, demonstrating significant improvements in both performance and material efficiency.

Another notable success story comes from Under Armour, which used generative design to develop their UA ArchiTech Futurist shoes. The program created complex lattice structures for the midsole that would have been impossible to conceptualize using traditional design methods, resulting in optimal cushioning and support.

Airbus achieved remarkable results by applying generative design to their A320 aircraft partition, reducing the component’s weight by 45% while maintaining all safety requirements. This optimization not only improved fuel efficiency but also demonstrated how generative design can transform manufacturing processes in highly regulated industries.

These commercial applications highlight how generative design is revolutionizing product development across various sectors, delivering improvements in efficiency, performance, and innovation.

Implementation Guidelines for Stone Fabricators

Getting Started with Generative Design

Beginning your journey with generative design requires a structured approach and careful planning. Start by clearly defining your project goals and constraints, as these parameters will guide the algorithm’s output. Before diving into complex projects, familiarize yourself with basic generative design concepts through tutorials and simple exercises available in your chosen software platform.

Select a generative design program that aligns with your specific needs and expertise level. Popular options include Autodesk’s Fusion 360, Grasshopper for Rhino, and specialized stone industry solutions that enhance the digital stone design process. Consider factors such as learning curve, compatibility with existing systems, and available support resources.

Begin with small-scale projects to build confidence and understanding. Start by implementing basic parameters like material constraints, structural requirements, and aesthetic preferences. As you become more comfortable, gradually introduce more complex variables and optimization goals.

Establish a systematic workflow that includes:

– Initial parameter setting

– Design space definition

– Iteration review and refinement

– Result validation

– Documentation of successful outcomes

Remember to regularly save and document your progress, as generative design often produces multiple viable solutions that you may want to revisit. Consider joining online communities and forums where you can share experiences and learn from other professionals implementing similar solutions.

Best Practices and Common Pitfalls

To maximize the benefits of generative design programs, start by clearly defining your project parameters and constraints. This foundational step ensures the algorithm generates relevant and feasible solutions. Regularly validate outputs against real-world manufacturing capabilities and budget constraints to avoid pursuing impractical designs.

A common pitfall is over-relying on automated solutions without human oversight. While generative design tools are powerful, they should complement rather than replace human creativity and expertise. Successful practitioners maintain a balanced approach, using the technology to explore possibilities while applying their professional judgment to refine results.

Ensure your team receives proper training before implementation. Many projects fail due to insufficient understanding of the software’s capabilities and limitations. Invest time in learning the tool’s features and establishing clear workflows for design review and iteration.

Avoid the temptation to immediately implement the most radical designs generated by the program. Instead, carefully evaluate each solution’s feasibility, considering factors like material costs, manufacturing complexity, and maintenance requirements. Start with smaller projects to build confidence and expertise before tackling more complex challenges.

Documentation is crucial. Maintain detailed records of input parameters, constraints, and decision-making processes. This practice helps track successful approaches and enables knowledge sharing across teams, preventing repeated mistakes and improving overall efficiency.

The future of generative design in stone fabrication stands at the cusp of a revolutionary transformation. As computational power continues to advance and algorithms become more sophisticated, we can expect to see increasingly innovative applications that push the boundaries of what’s possible with natural stone. The integration of artificial intelligence and machine learning will further enhance the capabilities of generative design software, enabling more efficient material usage, reduced waste, and unprecedented design possibilities.

The stone industry is likely to witness a significant shift towards automated design processes that consider multiple variables simultaneously – from structural integrity and material constraints to aesthetic preferences and sustainability requirements. This evolution will not only streamline production processes but also open new avenues for customization and creativity in stone applications.

We can anticipate closer collaboration between human designers and AI-powered tools, where the technology serves as an enabler rather than a replacement for human creativity. This symbiotic relationship will lead to more innovative solutions that balance artistic vision with practical constraints.

The democratization of generative design tools will make advanced stone fabrication techniques more accessible to smaller manufacturers and studios, potentially revolutionizing the industry’s landscape. As these technologies become more widespread, we’ll likely see a surge in sustainable practices, cost-effective solutions, and groundbreaking architectural achievements that showcase the full potential of natural stone in contemporary design.