Machine learning is revolutionizing equipment maintenance by detecting potential failures before they occur, reducing downtime by up to 50% and cutting maintenance costs by 40%. Through advanced sensor networks and AI-powered stone analysis, predictive maintenance systems continuously monitor critical equipment parameters, analyzing patterns that human operators might miss.

Unlike traditional scheduled maintenance, machine learning algorithms process vast amounts of real-time data to identify subtle changes in equipment behavior, temperature fluctuations, vibration patterns, and performance metrics. This precision enables maintenance teams to address issues at the optimal time – not too early, which wastes resources, and not too late, which risks catastrophic failure.

For industry professionals and facility managers, implementing predictive maintenance represents a paradigm shift from reactive to proactive operations. The technology not only extends equipment lifespan but also optimizes resource allocation, reduces energy consumption, and ensures consistent production quality. As sensor costs decrease and AI capabilities expand, predictive maintenance is becoming an essential tool for modern industrial operations, offering a clear competitive advantage in an increasingly efficiency-driven market.

Why Machine Learning Matters for Stone Maintenance

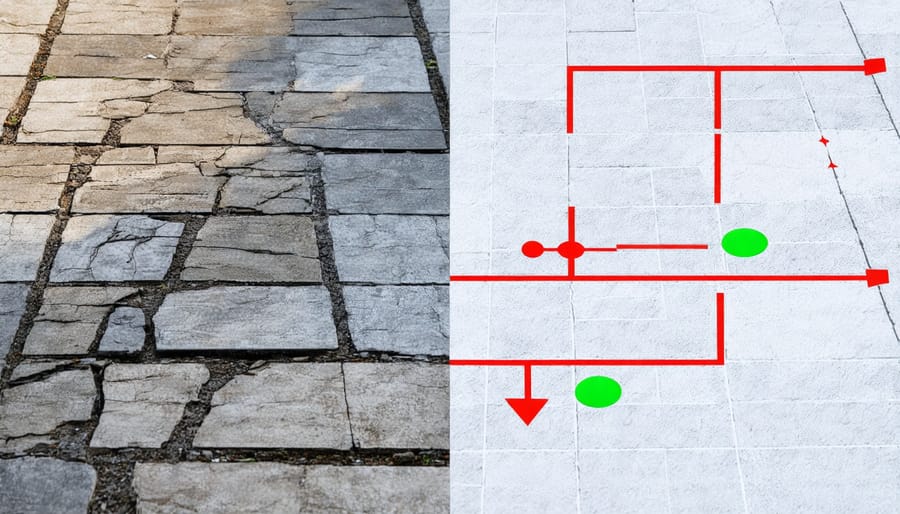

Common Stone Deterioration Patterns

Natural stone surfaces commonly exhibit several distinct deterioration patterns that can signal the need for maintenance intervention. Efflorescence, characterized by white crystalline deposits on the surface, often indicates moisture migration through the stone. Spalling, where layers of stone begin to peel or flake off, typically results from freeze-thaw cycles or salt crystallization.

Etching is particularly prevalent in calcium-based stones like marble and limestone, appearing as dull spots or rough patches caused by acidic substances. Surface erosion manifests as a gradual wearing away of the stone’s texture, while cracking can develop from structural stress or temperature fluctuations.

Biological growth, including algae, moss, and lichen, frequently occurs in outdoor applications and shaded areas, leading to discoloration and surface degradation. Staining from organic materials, metals, or environmental pollutants can penetrate the stone’s porous structure, creating persistent discoloration.

These deterioration patterns often progress predictably, making them ideal candidates for machine learning analysis. By monitoring these indicators through regular inspections and digital imaging, predictive maintenance systems can identify developing issues before they become severe problems requiring costly repairs.

The Limits of Traditional Maintenance

Traditional maintenance approaches in stone care typically fall into two categories: reactive maintenance, where repairs are made after problems occur, and scheduled maintenance, which follows a fixed timeline regardless of actual wear conditions. While these methods have served the industry for decades, they come with significant limitations and inefficiencies.

Reactive maintenance often leads to costly emergency repairs, extended downtime, and potential damage to surrounding materials. When problems are discovered only after they become visible, the required interventions tend to be more extensive and expensive. Scheduled maintenance, while more proactive, can result in unnecessary servicing of materials that don’t require attention while missing early signs of deterioration in other areas.

These conventional approaches also fail to account for varying environmental conditions, usage patterns, and material-specific wear characteristics. For instance, stone flooring in high-traffic areas may need more frequent maintenance than similar materials in low-traffic zones, yet traditional schedules treat them identically. Additionally, these methods rely heavily on human observation and experience, which can be subjective and may miss subtle signs of deterioration before they become serious issues.

How AI Predicts Stone Performance

Sensor Technology and Data Collection

Modern predictive maintenance relies heavily on sophisticated sensor networks that continuously monitor various aspects of stone processing equipment and installations. These sensors collect real-time data about vibration patterns, temperature fluctuations, moisture levels, and operational parameters that might indicate potential issues before they become critical problems.

Key monitoring systems typically include:

– Vibration sensors to detect unusual movement patterns

– Thermal imaging cameras for temperature monitoring

– Acoustic emission sensors that capture ultrasonic waves

– Moisture detection systems

– Pressure and flow sensors for hydraulic systems

– Environmental monitoring devices

The collected data feeds into advanced AI stone design solutions and analytics platforms, which process this information to identify patterns and anomalies. This comprehensive data collection approach enables maintenance teams to:

– Track equipment performance in real-time

– Establish baseline operational parameters

– Identify early warning signs of potential failures

– Monitor environmental conditions affecting stone installations

– Document maintenance history and equipment lifecycle

Modern IoT sensors can transmit this data wirelessly to central monitoring systems, allowing for remote observation and analysis. This technology has revolutionized how maintenance teams approach equipment care, shifting from reactive to proactive maintenance strategies while significantly reducing downtime and maintenance costs.

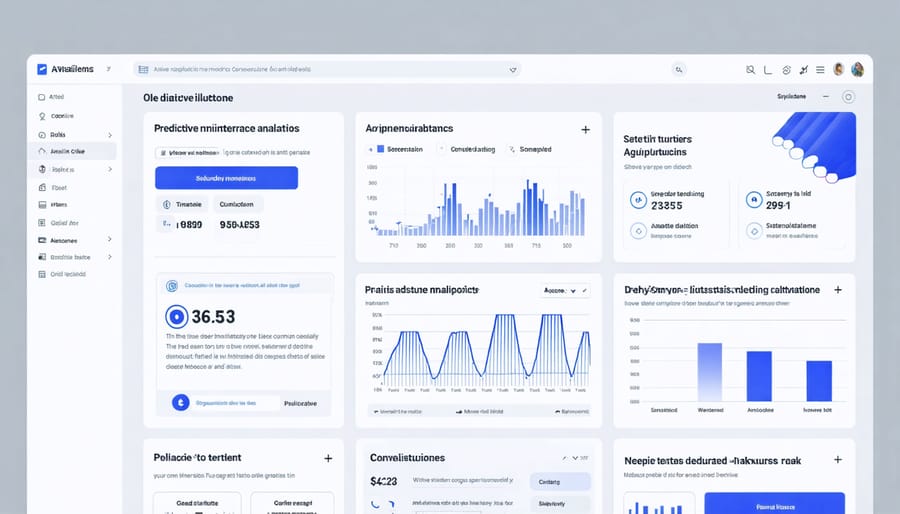

Key Performance Indicators

Key Performance Indicators (KPIs) in machine learning predictive maintenance serve as vital metrics that help monitor system health and predict potential failures. The most critical KPIs include Overall Equipment Effectiveness (OEE), which combines availability, performance, and quality metrics to provide a comprehensive view of equipment efficiency.

Mean Time Between Failures (MTBF) measures the average time between system breakdowns, while Mean Time To Repair (MTTR) indicates how quickly issues are resolved. These metrics help establish baseline performance and track improvement over time.

Condition monitoring indicators such as vibration levels, temperature readings, and acoustic emissions provide real-time data about equipment health. Machine learning algorithms analyze these parameters to detect anomalies and predict potential failures before they occur.

Asset reliability metrics, including failure rate and remaining useful life predictions, help maintenance teams prioritize interventions and optimize resource allocation. Performance degradation indicators track how equipment efficiency changes over time, enabling proactive maintenance scheduling.

Cost-related KPIs, such as maintenance cost per unit and downtime costs, help evaluate the economic impact of the predictive maintenance program. Quality metrics, including defect rates and first-pass yield, ensure that maintenance activities contribute to overall product quality improvement.

These indicators, when properly monitored and analyzed, enable organizations to move from reactive to predictive maintenance strategies, resulting in improved equipment reliability and reduced operational costs.

Real-World Applications

Commercial Building Success Stories

Several notable commercial buildings have demonstrated remarkable success with machine learning predictive maintenance systems for their natural stone installations. The iconic Somerset House in London implemented an AI-driven monitoring system in 2019, resulting in a 40% reduction in maintenance costs and early detection of potential limestone deterioration issues. Their success has paved the way for integrating advanced stone design techniques with predictive maintenance.

The Dubai Mall, featuring extensive marble installations across its 12 million square feet, deployed smart sensors and machine learning algorithms in 2020. The system continuously monitors foot traffic patterns, temperature fluctuations, and moisture levels, enabling predictive maintenance scheduling that has extended the life expectancy of their stone surfaces by an estimated 25%.

In Chicago, the Merchandise Mart’s recent renovation incorporated a comprehensive ML-based maintenance system for its travertine facades. The building’s management reports an 85% accuracy rate in predicting potential issues before they become visible, allowing for targeted interventions that have saved nearly $300,000 in annual maintenance costs.

These success stories demonstrate how machine learning predictive maintenance not only preserves the beauty and integrity of natural stone installations but also delivers significant cost savings and operational efficiencies for commercial properties.

Residential Applications

Smart home technology has revolutionized how homeowners maintain their properties, and machine learning predictive maintenance is at the forefront of this transformation. Modern homes equipped with IoT sensors can now monitor critical systems like HVAC, plumbing, and appliances in real-time, predicting potential failures before they occur.

For example, smart thermostats can analyze heating and cooling patterns, detecting unusual behaviors that might indicate a failing component. Connected water sensors can identify subtle changes in pressure or flow rates, warning homeowners about potential leaks or pipe issues before they cause significant damage.

Major appliances like refrigerators, washing machines, and dishwashers can now come equipped with sensors that monitor performance metrics. These systems learn from regular usage patterns and can alert homeowners when maintenance is needed, such as cleaning filters or replacing worn parts.

The benefits for homeowners are substantial: reduced repair costs, extended equipment lifespan, and fewer emergency breakdowns. Many systems can automatically schedule maintenance appointments or order replacement parts when needed, making home maintenance largely hands-off.

Energy efficiency also improves as systems operate at optimal levels. Some predictive maintenance solutions can even integrate with home insurance providers, potentially leading to reduced premiums due to lower risk of catastrophic failures and water damage.

For best results, homeowners should choose compatible smart devices and ensure proper system integration with their home automation platform.

Implementation Guidelines

Getting Started with Predictive Maintenance

Implementing predictive maintenance using machine learning begins with establishing a solid foundation of data collection and monitoring systems. Start by identifying critical maintenance parameters for your stone installations, such as temperature fluctuations, moisture levels, and wear patterns. Modern AR stone monitoring systems can help track these variables in real-time.

Next, gather historical maintenance records and combine them with current sensor data to create a comprehensive dataset. This information serves as the training foundation for your machine learning models. Consider implementing IoT sensors at key points to monitor surface conditions, structural integrity, and environmental factors affecting your stone installations.

Select appropriate machine learning algorithms based on your specific needs. For stone maintenance, common choices include random forests for predicting wear patterns and neural networks for identifying early signs of deterioration. Start with simpler models and gradually increase complexity as you gather more data and experience.

Establish clear maintenance thresholds and triggers based on your industry experience and historical data. These benchmarks will help calibrate your predictive models and ensure appropriate maintenance scheduling. Remember to regularly validate and adjust your models based on real-world outcomes and feedback from maintenance teams.

Begin with a pilot program on a smaller scale before full implementation. This approach allows you to refine your processes, identify potential challenges, and demonstrate value to stakeholders. Document all successes and lessons learned during this phase to guide future expansion of your predictive maintenance program.

Cost-Benefit Analysis

Implementing machine learning predictive maintenance systems requires careful consideration of both initial investments and long-term returns. The upfront costs typically include hardware sensors, data collection infrastructure, software development or licensing, and staff training. For a medium-sized facility, initial setup costs can range from $50,000 to $200,000, depending on the complexity of machinery and monitoring requirements.

However, the return on investment often justifies these initial expenses. Studies show that predictive maintenance can reduce machine downtime by 30-50% and extend equipment life by 20-40%. Organizations typically see maintenance cost savings of 25-30% annually, with some reporting payback periods as short as 6-12 months.

Consider a manufacturing plant that implemented ML-based predictive maintenance: Their $150,000 investment resulted in annual savings of $400,000 through reduced emergency repairs, optimized maintenance schedules, and increased production efficiency. The system paid for itself within five months.

Beyond direct financial benefits, ML predictive maintenance offers intangible advantages like improved safety conditions, enhanced product quality, and better resource allocation. Companies also report increased customer satisfaction due to fewer unexpected service interruptions.

The cost-benefit equation becomes more favorable as technology advances and implementation costs decrease. Cloud-based solutions and pre-trained models now make ML predictive maintenance more accessible to smaller organizations. When evaluating potential investments, consider both immediate maintenance savings and long-term strategic advantages, such as competitive edge and operational excellence.

Machine learning predictive maintenance represents a revolutionary advancement in stone care and preservation, offering unprecedented capabilities for protecting and maintaining valuable stone installations. By combining sensor technology, data analytics, and artificial intelligence, this innovative approach has demonstrated significant improvements in maintenance efficiency, cost reduction, and asset longevity.

The benefits are clear: reduced downtime, optimized maintenance schedules, early detection of potential issues, and substantial cost savings. Organizations implementing ML-based maintenance systems typically report 20-30% reductions in maintenance costs and up to 75% decrease in unexpected failures. These impressive results are driving increased adoption across the natural stone industry.

Looking ahead, the future of ML in stone maintenance appears exceptionally promising. Emerging technologies like advanced IoT sensors, edge computing, and improved machine learning algorithms will further enhance predictive capabilities. We can expect to see more sophisticated systems that can detect even subtler changes in stone conditions, provide more accurate predictions, and offer increasingly personalized maintenance recommendations.

The integration of augmented reality and mobile applications will make these systems more accessible to maintenance teams and property owners alike. As the technology continues to evolve and become more affordable, even smaller organizations will be able to implement predictive maintenance solutions, making this approach the new standard in stone care and preservation.