In a groundbreaking fusion of ancient craftsmanship and cutting-edge technology, 3D printing is revolutionizing how we shape and construct with stone. While traditional stone fabrication techniques have served us for millennia, advanced stone printing processes now enable architects and designers to create impossibly complex geometries and intricate structures with unprecedented precision.

This transformative technology combines natural stone particles with specialized binding agents, depositing them layer by layer to construct everything from decorative architectural elements to load-bearing structural components. The process not only reduces material waste by up to 30% compared to traditional methods but also opens up new possibilities for customization and design freedom that were previously unimaginable in stone construction.

As sustainability becomes increasingly crucial in construction, 3D-printed stone emerges as a compelling solution, offering the durability and beauty of natural stone while minimizing environmental impact through optimized material usage and reduced transportation needs. This technology stands at the intersection of ancient building materials and future construction methods, promising to reshape our approach to stone architecture in the 21st century.

How 3D Stone Printing Works

The Stone Printing Process

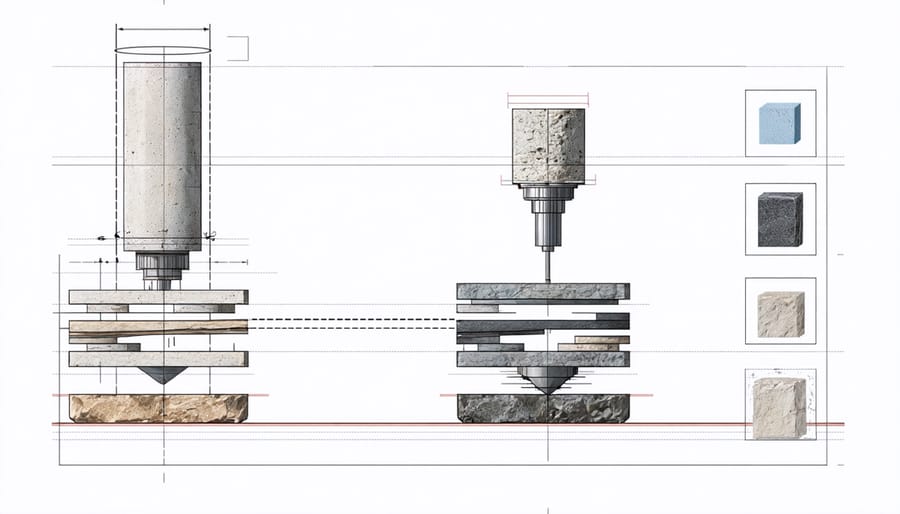

The 3D stone printing process builds upon traditional stone fabrication methods while introducing innovative techniques for creating complex structures. The process begins with material preparation, where natural stone is ground into a fine powder and mixed with specially formulated binding agents to create a printable material with the right viscosity and structural properties.

This stone mixture is loaded into the printer’s extrusion system, which maintains precise temperature and pressure controls. The printer then deposits the material layer by layer according to the digital design, with each layer typically ranging from 5 to 15 millimeters in thickness. As the material is extruded, it quickly begins to set, allowing subsequent layers to be added without compromising structural integrity.

Temperature management is crucial throughout the printing process, as it affects both the material’s flow characteristics and curing time. Most systems incorporate automated monitoring systems that adjust printing parameters in real-time to ensure optimal results. Once printed, the structure undergoes a curing period, during which the binding agents fully solidify, creating strong bonds between the stone particles.

Post-processing may include surface finishing techniques such as polishing or sealing to enhance durability and aesthetic appeal. The entire process typically takes several hours to days, depending on the size and complexity of the project.

Materials and Binding Agents

The materials used in stone 3D printing typically consist of two main components: the stone aggregate and the binding agent. Common stone materials include limestone, granite, and marble particles, which are finely ground into a powder or granular form. These natural stone particles are carefully selected for their size distribution and composition to ensure optimal printing results.

Binding agents play a crucial role in holding the stone particles together during and after the printing process. The most widely used binders include cement-based materials, geopolymers, and specialized organic polymers. Cement-based binders offer excellent structural stability and durability, while geopolymers provide enhanced environmental benefits due to their lower carbon footprint.

The ratio between stone particles and binding agents is critical for successful printing. Typically, the mixture contains 70-80% stone material and 20-30% binder, though these proportions can vary based on the specific application and desired properties of the final product. Some advanced formulations also incorporate additives such as plasticizers, accelerators, or reinforcing fibers to enhance workability, setting time, and structural performance.

Water content must be precisely controlled to achieve the right consistency for printing. The mixture should be fluid enough to flow through the printer nozzle smoothly while maintaining sufficient viscosity to hold its shape after extrusion. This delicate balance is essential for creating accurate, stable printed structures.

Applications in Architecture and Design

Custom Architectural Elements

3D printing technology has revolutionized the creation of custom architectural elements, offering unprecedented freedom in designing and producing intricate stone structures. Architects and designers can now create complex geometric patterns, ornate columns, and detailed facade elements that would be challenging or impossible to achieve through traditional stone fabrication methods.

The technology enables the production of precise replicas of historical architectural features, making it invaluable for restoration projects. Custom-designed columns can be printed with internal support structures that reduce weight while maintaining structural integrity. Decorative elements such as cornices, capitals, and friezes can be produced with exact specifications, ensuring perfect symmetry and consistent detail reproduction.

Facade elements represent another significant application, where 3D printing allows for the creation of modular components that seamlessly integrate with traditional building materials. These elements can incorporate complex patterns, textures, and functional features like integrated water management systems or mounting points for exterior fixtures.

The process also facilitates the production of unique architectural features such as curved wall panels, sculptural elements, and custom-designed building components. Designers can experiment with different stone compositions and finishing techniques to achieve specific aesthetic effects while maintaining structural requirements.

One of the most significant advantages is the ability to prototype architectural elements quickly. This allows architects and clients to evaluate designs in physical form before committing to full-scale production, reducing costs and ensuring design intent is accurately realized. The technology also enables the creation of lightweight alternatives to traditional stone elements, making installation easier and reducing structural load requirements.

Interior Design Applications

3D printing technology has revolutionized interior design possibilities for natural stone, offering unprecedented customization and creative freedom. Designers can now create intricate decorative pieces, custom tiles, and unique architectural elements that were previously impossible or cost-prohibitive using traditional stone fabrication methods.

Custom tiles represent one of the most promising applications, allowing designers to produce bespoke patterns, textures, and shapes that perfectly match their vision. From geometric patterns to organic designs, 3D-printed stone tiles can transform walls, floors, and feature areas into stunning artistic statements. The technology enables the creation of seamless transitions between different materials and can replicate complex historical patterns for restoration projects.

Decorative elements such as wall panels, sculptures, and architectural details can be produced with remarkable precision. designers can incorporate complex internal structures that reduce weight while maintaining strength, making installation easier and expanding placement possibilities. The technology excels in creating detailed relief work, custom moldings, and innovative lighting fixtures that integrate seamlessly with stone elements.

The process also allows for rapid prototyping of design concepts, enabling architects and designers to test different variations before committing to full-scale production. This capability has proven particularly valuable for high-end residential and commercial projects where unique aesthetic elements are essential.

Innovative applications include integrated functional elements such as built-in shelving, decorative room dividers, and custom fireplace surrounds. The ability to produce these elements in stone-based materials ensures durability while maintaining the natural beauty and tactile qualities that make stone a preferred material in interior design.

Benefits and Limitations

Advantages Over Traditional Methods

3D printing stone offers several compelling advantages over traditional stone manufacturing and sustainable stone installation methods. One of the most significant benefits is cost reduction through decreased material waste and labor requirements. While traditional stone cutting can waste up to 30% of raw materials, 3D printing uses only the exact amount needed for each project.

Customization capabilities are dramatically enhanced with 3D printing technology. Architects and designers can create complex geometries and intricate patterns that would be extremely difficult or impossible to achieve through conventional stone-working methods. This freedom of design allows for unique architectural elements and custom-fitted pieces without additional tooling costs.

The environmental impact is notably reduced through several factors. Besides minimizing waste material, 3D printing stone requires less energy consumption compared to traditional cutting and shaping processes. The technology also allows for local production, reducing transportation costs and associated carbon emissions.

Time efficiency is another crucial advantage. Projects that might take weeks using traditional methods can be completed in days with 3D printing. The automated process requires minimal human intervention, reducing labor costs and the potential for human error while maintaining consistent quality across production runs.

Additionally, the technology enables rapid prototyping and iteration, allowing designers to test and refine their concepts quickly before committing to full-scale production.

Current Challenges

Despite significant advances in 3D printing stone technology, several challenges remain that impact widespread adoption and optimal performance. The primary limitation is achieving consistent material properties throughout the printed structure. Natural stone particles can vary in size and composition, making it difficult to maintain uniform flow through printing nozzles and achieve predictable final properties.

Cost remains a significant barrier, as specialized equipment and materials for stone printing are considerably more expensive than traditional stone fabrication methods. The printing process is also relatively slow compared to conventional stone cutting and shaping techniques, limiting production efficiency for large-scale projects.

Resolution and surface finishing present ongoing challenges. Current technology struggles to achieve the fine detail and smooth surfaces that traditional stoneworking methods can produce. Post-processing is often necessary, which adds time and cost to projects.

Size constraints pose another limitation, as most stone 3D printers have restricted build volumes. This makes printing large architectural elements challenging and may require printing in sections that must be joined later.

Material waste management and recycling capabilities need improvement. While 3D printing is generally considered more sustainable than traditional methods, the handling of unused or failed print materials requires better solutions.

Technical expertise requirements present a barrier to entry, as operating stone 3D printing systems demands specialized knowledge in both digital fabrication and material science. This can make it difficult for traditional stone craftspeople to transition to this technology.

Future Prospects

The future of 3D printing stone technology holds immense promise for revolutionizing construction and design industries. Advanced research is currently focusing on developing more efficient printing methods and expanding the range of printable stone materials. Scientists and engineers are working on new binding agents that could enhance the structural integrity of printed stone while maintaining alignment with sustainable stone processing practices.

Emerging developments include the integration of artificial intelligence and machine learning to optimize printing parameters and material composition in real-time. This advancement could lead to improved print quality, reduced waste, and faster production speeds. Additionally, researchers are exploring hybrid manufacturing techniques that combine traditional stone crafting methods with 3D printing technology, potentially offering the best of both worlds.

The construction industry is likely to see significant changes as large-scale stone printing becomes more refined. Projects that currently take months could potentially be completed in weeks, with reduced labor costs and improved precision. Architects and designers will have greater freedom to create complex geometric structures that were previously impossible or cost-prohibitive with traditional stone fabrication methods.

Customization capabilities are expected to expand dramatically, allowing for the creation of unique stone elements that perfectly match specific project requirements. This could revolutionize historic preservation work, enabling the precise replication of damaged architectural elements while maintaining historical accuracy.

The technology’s impact on sustainability cannot be understated. Future developments in stone printing are focused on reducing material waste, incorporating recycled materials, and minimizing energy consumption during production. This aligns with growing demands for environmentally responsible construction practices and could help position stone as a leading sustainable building material for the future.

Market analysts predict significant growth in the stone 3D printing sector over the next decade, with new applications emerging across various industries, from construction to art and design. As the technology matures and becomes more accessible, we can expect to see increased adoption by smaller manufacturers and specialized fabricators, democratizing access to custom stone production.

The emergence of 3D printing technology in stone processing represents a significant leap forward in architectural and design capabilities. By combining traditional stone materials with modern digital fabrication techniques, this innovative approach is reshaping how we think about and work with natural stone. The ability to create complex geometries, reduce material waste, and maintain the authentic beauty of natural stone positions this technology at the forefront of sustainable construction practices.

As the technology continues to mature, we’re seeing increasingly sophisticated applications across various sectors, from historic preservation to contemporary architecture. The precision and efficiency offered by 3D stone printing not only streamlines production processes but also opens up new possibilities for customization and design freedom that were previously impractical or impossible with traditional stone working methods.

Looking ahead, the future of 3D stone printing appears promising, with ongoing developments in material science and printing technologies expected to further enhance its capabilities. This evolution will likely lead to more cost-effective solutions, improved material properties, and broader accessibility across the construction industry. For architects, designers, and stone professionals, embracing this technology means staying competitive while offering innovative solutions to their clients.

The integration of 3D printing with natural stone processing exemplifies how traditional materials can be reimagined through modern technology, creating a bridge between historic craftsmanship and future innovation. As sustainability becomes increasingly crucial in construction, this technology’s ability to minimize waste while maximizing creative potential makes it an invaluable tool for the future of architecture and design.