# Robotic Drywall Installation: What Stone Professionals Need to Know About Construction Automation

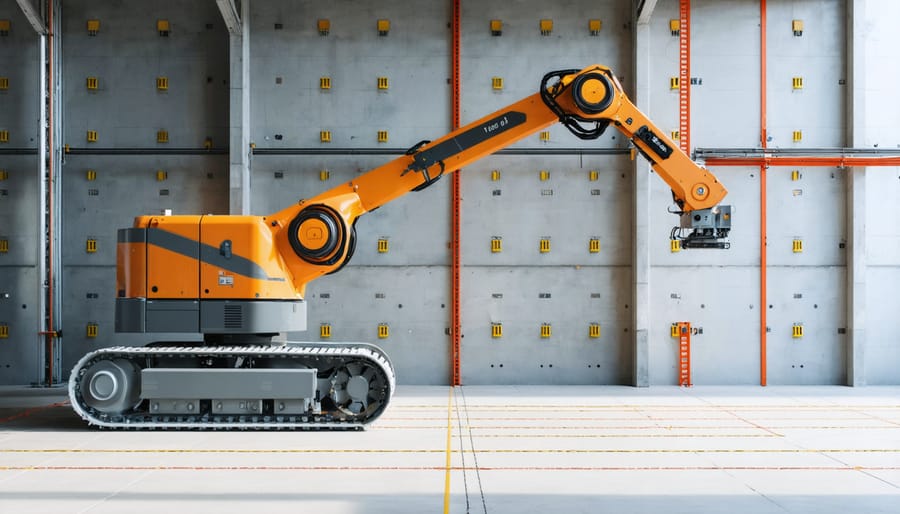

Construction robotics have moved from laboratory curiosity to jobsite reality. Canvas, a commercial construction robotics company, deployed the first drywall-finishing robot in 2018, demonstrating that machines could match human precision in vertical surface applications. By 2023, robotic systems were hanging, mudding, and sanding drywall panels across multi-story buildings at speeds 30% faster than traditional crews—a transformation that mirrors the automation trajectory now emerging in natural stone installation.

The parallels between drywall and stone work run deeper than surface-level similarities. Both trades demand precise measurement, material handling of heavy panels or slabs, exact positioning against vertical surfaces, and quality finishing that meets exacting standards. The robotics solving drywall’s labor challenges—positioning systems, material manipulation arms, and sensor-guided placement tools—translate directly to stone installation obstacles. Understanding how automation conquered drywall’s technical barriers provides stone professionals with a roadmap for their own industry’s inevitable mechanization.

Today’s stone industry stands where drywall installation stood five years ago: facing persistent labor shortages, rising material costs, and increasing demand for faster project completion. Major fabricators are already experimenting with automated cutting, CNC machining, and robotic polishing systems. Yet widespread adoption of installation robotics remains nascent, creating a critical window for professionals to understand these technologies before they fundamentally reshape competitive dynamics in stone work.

The Current State of Robotic Drywall Installation

Leading Robotic Drywall Systems on Job Sites Today

The construction industry has witnessed significant advances in robotic drywall installation, with several systems now operating on commercial job sites. Canvas, a San Francisco-based company, leads this transformation with their robotic system that combines advanced sensors, machine learning, and precision robotics to finish drywall automatically. Their robot can sand, smooth, and level drywall surfaces with consistent accuracy rates exceeding 98%, completing tasks in roughly half the time of traditional manual methods.

Canvas’s system uses LiDAR scanning and computer vision to map wall surfaces, identifying imperfections and calculating optimal finishing paths. The robot applies joint compound with precise consistency, eliminates human error, and operates in challenging conditions without fatigue. Commercial contractors report that Canvas installations reduce labor costs by approximately 30-40% while improving finish quality and project timelines.

Other emerging solutions include systems focused on measurement and layout automation, robotic lifting devices for panel placement, and automated taping systems. These technologies demonstrate capabilities directly applicable to stone installation: precision measurement, consistent material application, heavy material handling, and quality verification through digital scanning.

Adoption rates in commercial construction have grown substantially, with major general contractors incorporating robotic drywall systems into multifamily housing, hospitality, and office projects. The success of these platforms validates the business case for construction robotics and provides a roadmap for automation in related trades. For stone professionals, these systems offer valuable insights into how robotics handle similar challenges—material weight, surface preparation, precise placement, and quality control—challenges inherent to natural stone installation.

How These Robots Actually Work

Robotic drywall installation systems operate through a coordinated sequence of advanced technologies that work together seamlessly. Understanding these core components helps illuminate how similar automation could revolutionize material handling across construction trades, including stone installation.

The process begins with **3D scanning and mapping**, where laser scanners and depth cameras capture precise room dimensions, creating a detailed digital blueprint. This environmental mapping identifies wall surfaces, structural elements, and obstacles—ensuring robots know exactly where materials need placement. These scanning systems achieve millimeter-level accuracy, far exceeding human measurement capabilities.

Next comes **precision positioning technology**. Robotic arms mounted on mobile platforms use the scanned data to navigate spaces autonomously. Advanced sensors and computer vision systems enable real-time adjustments, compensating for uneven floors or unexpected obstacles. The robots calculate optimal positioning angles and maintain consistent alignment throughout installation.

For **material handling**, robotic lifts and grippers transport drywall sheets weighing up to 100 pounds with mechanical assistance. These systems incorporate vacuum suction cups or adjustable clamps that secure materials without damage while maneuvering them into precise positions overhead or along walls—eliminating the physical strain that causes worker injuries.

Finally, **automated fastening systems** drive screws at predetermined intervals with consistent depth and spacing. Integrated sensors detect studs behind surfaces, while torque-controlled drivers prevent over-tightening. This automation ensures uniform installation quality while dramatically reducing completion time compared to manual methods.

Together, these technologies demonstrate principles directly applicable to handling heavy stone materials, where precision, consistency, and worker safety are equally critical concerns.

Parallels Between Drywall and Stone Installation Challenges

Material Handling and Weight Management

Robotic systems in drywall installation have pioneered solutions for one of construction’s most physically demanding challenges: repetitive lifting and positioning of heavy materials. Standard drywall sheets weigh 50-70 pounds, requiring multiple workers and creating significant ergonomic strain. Robotic lifts and positioning systems now handle this burden autonomously, reducing workplace injuries and improving installation precision.

The stone industry faces even more extreme weight challenges. Natural stone slabs typically weigh 400-1,000 pounds or more, making manual handling virtually impossible without mechanical assistance. However, the fundamental ergonomic and safety concerns mirror those in drywall work—reducing human exposure to heavy lifting, preventing musculoskeletal injuries, and minimizing material damage during handling.

Current stone fabrication already employs bridge cranes, vacuum lifters, and A-frame carts for material transport. The evolution toward robotic automation represents a natural progression, applying lessons learned from drywall robotics to even heavier materials. Advanced robotic systems can now manipulate massive stone slabs with millimeter precision, maintaining consistent grip pressure to prevent cracking while positioning panels for installation. This technological convergence demonstrates how automation solutions developed for one material can inform and accelerate innovation in another, ultimately making construction safer and more efficient across all applications.

Precision Measurement and Placement

Both robotic drywall installation and automated stone placement demand exceptional precision to meet modern construction standards. These systems must achieve millimeter-level accuracy repeatedly across hundreds of installations, ensuring consistent quality that exceeds manual capabilities.

In drywall applications, robotic systems use laser scanning and advanced sensors to map spaces and position panels within 2-3mm tolerances. This same precision translates directly to stone installation, where proper alignment prevents lippage, ensures uniform grout lines, and creates seamless visual patterns—particularly critical for book-matched slabs and complex mosaics.

The challenge extends beyond simple placement. Both technologies must adapt to real-world conditions: walls that aren’t perfectly plumb, floors with slight variations, and architectural features that deviate from blueprints. Modern robotic systems employ continuous feedback loops, adjusting in real-time as they work.

For stone installations, this adaptability becomes even more crucial. Natural stone’s inherent variations in thickness and surface texture require robots to measure each piece individually and compensate accordingly. The technology must also account for stone’s weight distribution and fragility—factors less critical with lightweight drywall panels. Successfully meeting these precision requirements demonstrates how construction robotics can handle increasingly demanding materials and specifications.

What Stone Installation Can Learn from Drywall Robotics

Site Scanning and Digital Mapping Technologies

The most transformative technology from robotic drywall systems is 3D laser scanning and digital mapping. These systems create precise digital twins of installation surfaces by capturing millions of data points within minutes, measuring irregularities down to millimeters. In drywall applications, this technology identifies studs, electrical boxes, and surface variations to guide robotic cutting and placement.

For natural stone installation, this same scanning technology offers remarkable potential. Before templating, 3D scanners can capture exact wall dimensions, floor layouts, and existing architectural features. The resulting digital model allows fabricators to visualize how stone slabs will fit within the actual space, accounting for every corner, outlet, and irregular surface condition. This eliminates costly field errors and reduces material waste significantly.

Leading stone fabrication shops are already adopting similar scanning technologies for countertop templating, demonstrating the practical viability of this approach. The scanner data integrates directly with CNC cutting equipment, creating a seamless digital workflow from measurement to installation. As these systems become more affordable and user-friendly, the technology pioneered in drywall robotics is poised to revolutionize how the stone industry approaches complex installations, particularly for large-format panels and intricate architectural applications.

Automated Positioning and Alignment Systems

The precision required in stone slab placement—where millimeter-level accuracy determines both aesthetic quality and structural integrity—makes robotic positioning systems particularly valuable. These automated systems, already proven in drywall applications, employ advanced sensors and computer-controlled actuators to position heavy materials with exceptional accuracy while eliminating the physical strain on installers.

Modern robotic positioning platforms utilize laser guidance systems and 3D mapping technology to locate exact placement coordinates. The robotic arm maintains consistent pressure and angle throughout installation, addressing one of stone fabrication’s most challenging aspects: ensuring uniform contact with adhesive substrates. Unlike human operators who may tire during extended installation sessions, robotic systems maintain consistent precision across multiple slabs.

These systems typically feature vacuum-grip technology specifically designed for smooth stone surfaces, capable of handling slabs weighing several hundred pounds. Real-time feedback sensors detect even subtle misalignments, automatically correcting positioning before final placement. For large-format porcelain panels and natural stone installations in commercial settings, this technology significantly reduces installation time while improving seam alignment.

The ergonomic benefits are substantial—installers transition from physically demanding lifting to supervisory roles, operating control interfaces while the robot handles material manipulation. This shift not only reduces workplace injuries but also allows skilled craftspeople to focus on detail work and quality control rather than heavy lifting.

Integration with Existing Workflows

The drywall robotics revolution offers a crucial lesson for stone professionals: automation works best as a collaborative tool rather than workforce replacement. Leading drywall companies have found that robots excel at physically demanding, repetitive tasks—lifting heavy panels, maintaining precise positioning, and reducing worker strain—while human craftspeople focus on quality control, complex cuts, and finish work requiring nuanced judgment.

This collaborative model directly applies to natural stone installation. Robots could handle material transport, initial positioning, and precise leveling, while installers concentrate on seam matching, veining alignment, and artistic layout decisions that require aesthetic expertise. Early adopters in drywall report that workers transition from purely physical labor to supervisory roles, operating equipment and solving complex installation challenges. This upskilling approach increases job satisfaction while improving productivity—a model that preserves the craftsmanship essential to premium stone installation while embracing technological advancement.

Current Robotic Innovations in Stone Installation

Robotic Stone Handling and Lifting Systems

Heavy material handling represents one of the most physically demanding aspects of construction work, making it a prime candidate for robotic assistance. In robotic stone installation, several technologies are emerging to address the unique challenges of manipulating large, heavy stone panels.

Vacuum lifting systems have become increasingly sophisticated, utilizing multiple suction points and intelligent pressure sensors to safely grip stone surfaces without damage. These systems can handle slabs weighing several hundred pounds while maintaining precise control throughout the lifting process. Modern units often incorporate tilt and rotation capabilities, allowing installers to position materials at optimal angles during placement.

Robotic arms designed for construction applications are being adapted for stone work, featuring enhanced payload capacities and specialized end-effectors. These systems offer six-axis movement, enabling complex maneuvering in tight spaces where traditional equipment struggles.

Exoskeleton technologies are also gaining traction, augmenting human workers’ strength rather than replacing them entirely. These wearable devices reduce physical strain during manual handling tasks, decreasing injury risk while maintaining the craftsmanship and decision-making abilities that experienced installers provide.

Automated Stone Cutting and Fabrication

The natural stone industry has already embraced automation in significant ways, particularly in the cutting and fabrication stages. Computer Numerical Control (CNC) machines have revolutionized how stone is shaped, cut, and finished in fabrication shops worldwide. These sophisticated systems use digital templates to execute precise cuts, create intricate edge profiles, and drill sink cutouts with accuracy that far exceeds manual methods.

Modern stone fabrication technologies include waterjet cutting systems that slice through granite and marble with pinpoint precision, robotic polishing arms that achieve consistent surface finishes, and automated slab handling systems that reduce workplace injuries. Some advanced facilities now employ fully automated production lines where slabs enter as raw material and emerge as finished countertops, requiring minimal human intervention beyond programming and quality control.

This fabrication automation has delivered measurable benefits: reduced material waste, faster production times, improved worker safety, and consistent quality. These same advantages are now driving interest in extending automation beyond the shop floor to the actual installation site—a transition that parallels the journey of drywall installation robotics.

The Business Case: Why Automation Matters Now

Addressing Labor Shortages and Physical Demands

The construction industry faces a critical shortage of skilled labor, with experienced installers retiring faster than new workers enter the field. This challenge is particularly acute in stone installation, where the physical demands are substantial—lifting heavy slabs, working in awkward positions, and performing repetitive motions that lead to chronic injuries. Robotics offers a practical solution to both problems simultaneously.

Automated systems can handle the most physically demanding tasks, such as lifting large stone panels and maintaining precise positioning during installation. This reduces the risk of back injuries, joint strain, and repetitive stress injuries that plague manual installers. By shouldering the heavy lifting, robots allow human workers to focus on skilled tasks requiring judgment and craftsmanship—quality control, detail work, and complex problem-solving.

For businesses, this technology helps address workforce challenges while potentially reducing stone installation costs associated with workplace injuries and insurance premiums. Younger workers may find stone installation more appealing when robotic assistance minimizes physical strain, helping attract new talent to the industry. Rather than replacing craftspeople, robotics can extend careers and make the profession more sustainable for future generations.

Quality Consistency and Customer Expectations

In today’s construction environment, clients and architects expect flawless finishes with minimal margin for error. Robotic drywall installation systems demonstrate how automation addresses these heightened expectations through unprecedented precision and repeatability. These systems use laser-guided measurements and computer-controlled movements to achieve tolerances within millimeters, eliminating the inconsistencies inherent in manual installation.

The technology’s impact on quality control extends beyond initial installation. By reducing human error in measurements, cutting, and placement, robotic systems significantly decrease the callbacks and rework that plague traditional construction projects. Industry data shows that automated drywall installation can reduce installation defects by up to 60%, translating to substantial cost savings and improved client satisfaction.

For natural stone applications, where material costs are considerably higher and tolerances even more critical, these quality assurance benefits become even more compelling. Stone installation demands precision not just for aesthetic reasons but for structural integrity and longevity. The lessons learned from robotic drywall systems—particularly in maintaining consistent quality across large projects and multiple installation teams—offer valuable insights for developing similar automation solutions in stone fabrication and installation, where meeting exacting standards is paramount to project success.

Preparing for the Future of Stone Installation

Stone installation professionals who want to remain competitive in an increasingly automated construction industry should begin preparing now, even as robotic technologies continue to evolve. The first step is investing in digital literacy and technical training. Understanding CAD software, 3D modeling, and digital fabrication processes will become essential as robotic systems require precise digital templates to operate effectively. Many industry associations and trade schools now offer courses in construction technology that bridge traditional craftsmanship with digital tools.

Building relationships with technology providers and staying informed about automation developments is equally important. Attend industry trade shows, participate in pilot programs, and connect with companies developing robotic solutions for construction. Early adopters often gain valuable input into how these technologies develop, ensuring the final products meet real-world needs.

Consider gradually introducing automated equipment into your operations. CNC machines for cutting and shaping stone represent an accessible entry point into automation. These tools complement traditional skills while improving precision and efficiency. As you gain comfort with semi-automated processes, transitioning to more advanced robotic systems becomes less daunting.

Reassess your business model to identify which tasks could benefit most from automation. Repetitive, physically demanding work like material handling or initial surface preparation may be ideal candidates, allowing skilled craftspeople to focus on complex installation details and custom work that requires human judgment and artistry.

Finally, embrace a mindset of continuous learning. The construction industry is experiencing rapid technological change, and professionals who view automation as a tool to enhance rather than replace their expertise will find the greatest success. Document your processes, standardize best practices, and remain flexible as new technologies emerge that can improve safety, efficiency, and installation quality.

The evolution of robotic drywall installation isn’t just a parallel story to stone automation—it’s a preview of what’s coming. Every challenge the drywall industry has tackled with robotics, from material handling to precision placement, mirrors obstacles that stone fabricators and installers currently face. The difference is timing. While drywall automation has reached commercial viability, stone installation robotics remains in its formative stages, creating a critical window of opportunity.

Industry professionals who recognize these patterns now position themselves to lead rather than follow. Understanding how Canvas and similar technologies solved complex construction automation problems provides a competitive advantage, offering insights into equipment investments, workforce development, and process optimization that will define the next decade of stone installation.

The roadmap is clear: automation will transform stone installation from a labor-intensive craft into a precision-driven, technology-enhanced process. Those who view robotic drywall installation as merely adjacent technology will miss the blueprint for their own industry’s future. Early adopters who invest in understanding these systems, training their teams, and adapting their business models will distinguish themselves as industry leaders, while others scramble to catch up in an increasingly automated marketplace.