Carbon nanotube sensors represent a groundbreaking advancement in smart building technology, revolutionizing how we monitor and respond to environmental changes at the molecular level. These microscopic carbon structures, measuring just billionths of a meter in diameter, detect minute variations in temperature, pressure, and chemical composition with unprecedented accuracy. Their exceptional sensitivity and rapid response times make them ideal for applications ranging from structural health monitoring in buildings to advanced medical diagnostics.

What sets carbon nanotube sensors apart is their remarkable combination of size, durability, and versatility. Unlike traditional sensors, these nanoscale devices can be seamlessly integrated into existing materials without compromising structural integrity. Their ability to operate at room temperature while consuming minimal power positions them as a sustainable solution for long-term monitoring applications.

As industries increasingly demand real-time, precise environmental data, carbon nanotube sensors emerge as a critical tool in the evolution of intelligent monitoring systems. Their implementation marks a significant step forward in creating more responsive, efficient, and safer built environments.

Understanding Carbon Nanotube Sensor Technology

What Are Carbon Nanotubes?

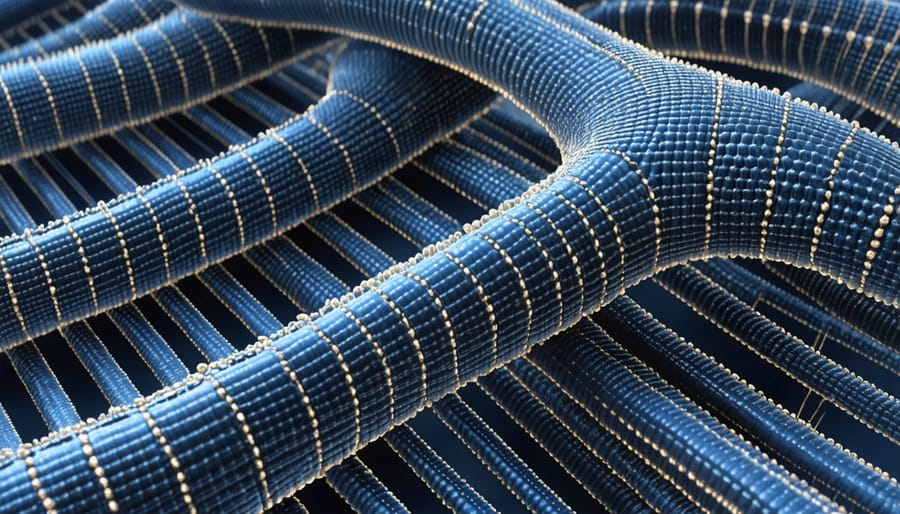

Carbon nanotubes are microscopic cylindrical structures made of carbon atoms arranged in a hexagonal pattern. These remarkable materials, discovered in the 1990s, are essentially rolled sheets of graphene with a diameter thousands of times smaller than a human hair. What makes carbon nanotubes particularly special is their unique combination of mechanical, electrical, and chemical properties.

These tiny tubes can be either single-walled (SWCNT) or multi-walled (MWCNT), with each configuration offering distinct advantages. They exhibit exceptional strength-to-weight ratios, being stronger than steel while remaining incredibly lightweight. Their electrical conductivity rivals or exceeds that of copper, and they demonstrate remarkable thermal conductivity properties.

Most importantly for sensing applications, carbon nanotubes are highly sensitive to changes in their environment. Even slight variations in temperature, pressure, or chemical composition can alter their electrical properties, making them ideal candidates for advanced sensing technologies. Their nanoscale dimensions also allow them to be integrated into extremely compact devices without compromising performance.

How These Sensors Work

Carbon nanotube sensors operate through a remarkably simple yet effective mechanism. These microscopic tubes, made from rolled sheets of carbon atoms, change their electrical properties when they come into contact with specific molecules or environmental conditions. Think of them as tiny electrical switches that respond to their surroundings.

When target molecules interact with the surface of the nanotubes, they cause measurable changes in electrical conductivity. This change can be precisely measured and translated into useful data about the presence and concentration of various substances. For example, when monitoring moisture levels in stone structures, water molecules binding to the nanotubes create distinctive electrical signals that indicate the exact moisture content.

The sensors can be customized to detect different substances by modifying their surface chemistry. This customization allows them to respond selectively to specific molecules while ignoring others, making them highly accurate and reliable. The sensors can operate continuously and provide real-time data, making them ideal for monitoring environmental conditions that might affect stone integrity.

Their incredibly small size allows them to be integrated into materials without affecting appearance or structural properties, while their high sensitivity enables detection of even minute changes in conditions.

Applications in Natural Stone Monitoring

Moisture Detection

Carbon nanotube sensors excel at detecting moisture levels within stone materials through their unique electrical properties. When moisture comes into contact with the nanotubes, it alters their electrical conductivity, creating measurable changes that can be precisely monitored and quantified.

These sensors are typically embedded within or applied to the surface of stone materials in a thin, nearly invisible layer. The carbon nanotubes form a complex network that acts as a highly sensitive moisture detection system. As water molecules interact with the nanotubes, the electrical resistance of the network changes proportionally to the amount of moisture present.

The detection process is both rapid and accurate, with sensors capable of identifying moisture levels as low as 0.1%. This sensitivity allows for early detection of potential moisture-related issues before they become visible to the naked eye or cause damage to the stone.

Real-time monitoring systems can be connected to these sensors, providing continuous data on moisture conditions. This information helps facility managers and conservation specialists make informed decisions about environmental controls and maintenance schedules. The system can trigger alerts when moisture levels exceed predetermined thresholds, enabling proactive intervention.

The durability of carbon nanotube sensors makes them particularly suitable for long-term stone monitoring applications, with many systems maintaining their effectiveness for several years without requiring replacement or significant maintenance.

Structural Integrity Monitoring

Carbon nanotube sensors have revolutionized structural integrity monitoring by enabling the detection of microscopic changes long before they become visible problems. These sophisticated sensors can detect minute structural shifts, stress patterns, and early signs of material fatigue with remarkable precision.

When integrated into natural stone structures, these sensors create an invisible monitoring network that continuously assesses the material’s condition. They can detect subtle changes in pressure distribution, identify developing crack patterns, and monitor moisture penetration – all critical factors in maintaining structural integrity.

The sensors work by measuring electrical conductivity changes when the carbon nanotubes experience mechanical stress or deformation. This data is collected in real-time and can be analyzed to identify potential issues before they escalate into serious structural problems. For example, if a stone column begins to experience unusual stress patterns, the sensors can alert maintenance teams immediately, allowing for proactive intervention.

Installation typically involves embedding these sensors during construction or applying them to existing structures through specialized coating systems. The sensor network can be customized based on the specific monitoring needs of different areas within the structure.

This technology has proven particularly valuable in historic preservation, where early detection of structural issues is crucial for maintaining architectural heritage. It also provides building managers with data-driven insights for planning maintenance schedules and ensuring long-term structural stability.

Environmental Impact Detection

Carbon nanotube sensors play a crucial role in detecting and monitoring various environmental factors that can affect stone quality in both indoor and outdoor applications. These advanced sensors can measure multiple parameters simultaneously, providing comprehensive data about the stone’s surrounding environment and potential threats to its integrity.

The sensors are particularly effective at detecting moisture levels, temperature fluctuations, and harmful atmospheric pollutants that could compromise stone surfaces. When integrated into sustainable IoT applications, these sensors create an early warning system that alerts property managers to potential issues before visible damage occurs.

Key environmental factors monitored by these sensors include:

– Relative humidity and condensation risks

– Acid rain exposure and pH levels

– UV radiation intensity

– Air pollution concentrations

– Temperature variations and thermal stress

The real-time data collected helps professionals implement preventive maintenance strategies and adjust environmental controls accordingly. For example, when sensors detect elevated moisture levels near stone surfaces, ventilation systems can be automatically activated to prevent potential water damage or mold growth.

This proactive approach to environmental monitoring has proven particularly valuable in heritage conservation, modern architecture, and high-value stone installations where maintaining optimal conditions is crucial for preserving the material’s aesthetic and structural properties.

Benefits for Stone Industry Professionals

Preventive Maintenance

Carbon nanotube sensors have revolutionized preventive maintenance strategies by enabling real-time monitoring of structural health and environmental conditions. These advanced sensors detect minute changes in pressure, strain, and chemical composition before issues become visible to the naked eye, allowing facility managers and maintenance teams to address potential problems proactively.

The sensors continuously collect data about material stress, temperature fluctuations, and moisture levels, creating a comprehensive picture of the structure’s condition. This constant monitoring helps identify patterns and predict when maintenance might be needed, rather than waiting for visible damage to occur. For example, in natural stone applications, these sensors can detect early signs of stress that might lead to cracking or deterioration.

The preventive approach enabled by carbon nanotube sensors typically reduces maintenance costs by 20-30% compared to reactive maintenance strategies. By identifying issues early, repairs can be scheduled during planned downtime, minimizing disruption to operations. The sensors also help extend the lifespan of materials by ensuring optimal environmental conditions are maintained.

Integration with building management systems allows for automated alerts when parameters exceed preset thresholds. This automation reduces the need for manual inspections while providing more accurate and consistent monitoring. Maintenance teams can prioritize their efforts based on actual condition data rather than fixed schedules, making resource allocation more efficient and effective.

Quality Assurance

Carbon nanotube sensors play a crucial role in maintaining and monitoring stone quality throughout various applications in modern stone architecture. These advanced sensors provide real-time data on critical parameters such as moisture content, structural stress, and temperature variations, ensuring that stone installations maintain their integrity over time.

Quality assurance protocols utilizing these sensors typically involve a three-step monitoring process. First, sensors embedded within the stone material continuously collect data on environmental conditions and material response. Second, this information is processed through sophisticated algorithms that can detect subtle changes indicating potential quality issues. Finally, automated alerts notify maintenance teams when measurements fall outside predetermined acceptable ranges.

The implementation of carbon nanotube sensors has revolutionized quality control in stone applications by enabling proactive maintenance approaches. For instance, these sensors can detect early signs of moisture infiltration before visible damage occurs, allowing for timely intervention and preservation of stone quality. They also monitor structural stability by measuring micro-movements and stress distributions, particularly important in load-bearing applications.

Industry standards now increasingly recommend the integration of these sensor systems, particularly in high-value installations where maintaining stone quality is paramount. The data collected not only ensures immediate quality control but also contributes to long-term understanding of stone behavior under various conditions, leading to improved installation and maintenance practices.

Implementation Considerations

Cost-Benefit Analysis

Implementing carbon nanotube sensors in natural stone applications requires careful consideration of both initial investments and long-term returns. The upfront costs typically include sensor hardware ($500-2,000 per unit), installation labor ($200-400 per location), and integration with existing monitoring systems ($1,000-3,000). However, these expenses are often offset by substantial long-term benefits.

The primary financial advantages come from preventive maintenance and damage prevention. Early detection of structural issues can save building owners 40-60% on repair costs compared to reactive maintenance. When integrated with sustainable stone solutions, these sensors can reduce energy consumption by 15-25% through optimized climate control and moisture management.

Insurance providers often offer premium reductions of 10-20% for properties equipped with advanced monitoring systems, recognizing the reduced risk of catastrophic failures. Additionally, the extended lifespan of monitored stone installations typically ranges from 25-40% longer than unmonitored installations, representing significant long-term value.

The return on investment (ROI) generally becomes positive within 2-3 years of implementation, with some installations reporting complete cost recovery in as little as 18 months. When factoring in reduced maintenance costs, extended material longevity, and potential insurance savings, the lifetime value proposition of carbon nanotube sensors becomes particularly compelling for large-scale stone installations.

Installation and Maintenance

The successful implementation of carbon nanotube sensors requires careful attention to both installation and ongoing maintenance procedures. During installation, sensors should be placed strategically in areas where monitoring is most critical, such as high-stress points or locations prone to environmental exposure. The mounting surface must be properly prepared and cleaned to ensure optimal sensor adhesion and performance.

Installation typically involves a multi-step process: surface preparation, sensor positioning, connection to monitoring systems, and initial calibration. Professional installation is recommended to ensure proper integration with existing monitoring infrastructure and accurate baseline readings.

Regular maintenance is crucial for long-term reliability. Monthly visual inspections should check for physical damage or deterioration of sensor components. Quarterly calibration checks help maintain measurement accuracy, while annual comprehensive testing ensures all systems are functioning within specified parameters.

Environmental factors such as temperature fluctuations, humidity, and exposure to chemicals can affect sensor performance. Protective housing or coatings may be necessary in harsh environments. It’s important to maintain detailed maintenance logs and establish clear protocols for addressing any detected issues.

Sensor systems should include redundancy measures and backup power supplies to prevent data loss during system failures. Regular software updates and data backup procedures are essential parts of the maintenance routine. Training staff in basic troubleshooting and maintenance procedures can help minimize system downtime and ensure consistent performance.

Carbon nanotube sensors represent a significant leap forward in natural stone monitoring and maintenance. Their ability to detect minute changes in stress, temperature, and moisture has revolutionized how we protect and preserve valuable stone installations. As the technology continues to evolve, we can expect even more sophisticated applications, including integrated smart monitoring systems and predictive maintenance capabilities.

The future outlook for carbon nanotube sensors in natural stone applications is promising. Ongoing research suggests potential developments in wireless connectivity, improved durability, and enhanced sensitivity. These advancements will likely lead to more cost-effective solutions and wider adoption across the industry. For property owners, architects, and stone professionals, this means better protection of investments, reduced maintenance costs, and longer-lasting stone installations.

As we move forward, carbon nanotube sensors will play an increasingly crucial role in preserving the beauty and integrity of natural stone while ensuring its sustainable use in modern architecture and design.