Water shapes our planet’s destiny, flowing through four interconnected storage systems that sustain both life and eco-friendly stone operations. From the vast oceans that cover 71% of Earth’s surface to the frozen polar caps, underground aquifers, and atmospheric moisture, these reservoirs form a dynamic cycle that directly impacts natural stone formation and extraction.

Understanding these water storage systems is crucial for stone industry professionals, as each reservoir type influences quarrying methods, processing techniques, and long-term resource management. Whether managing groundwater in quarry operations or adapting to changing precipitation patterns, knowledge of Earth’s water distribution enables more efficient and sustainable stone production practices.

This comprehensive exploration reveals how these four major water storage areas affect stone industry operations and provides practical insights for optimizing water usage in natural stone applications.

Surface Water Storage: Rivers, Lakes, and Reservoirs

Impact on Quarrying Operations

Surface water plays a crucial role in quarrying operations, directly impacting both extraction processes and operational efficiency. Quarry operators must carefully manage surface water accumulation from rainfall and natural drainage to maintain safe working conditions and protect equipment. During heavy precipitation, excess water can flood quarry pits, potentially halting operations and requiring costly pumping systems to remove.

Water management strategies typically include creating drainage channels, settling ponds, and water recycling systems. These systems help control water flow while ensuring environmental compliance and sustainable resource usage. Proper surface water management also prevents erosion, maintains pit wall stability, and protects groundwater quality.

In stone processing facilities, water serves as a vital cooling agent during cutting and polishing operations. However, excessive surface water can compromise the structural integrity of access roads and working platforms, potentially creating hazardous conditions for heavy machinery and workers.

Modern quarries increasingly implement sophisticated water management technologies, including automated pumping systems and water quality monitoring equipment. These innovations help maintain optimal operating conditions while meeting environmental regulations. Additionally, many operations now incorporate water conservation measures, such as closed-loop processing systems, to minimize environmental impact and reduce operational costs.

Water Management Strategies

Effective water management strategies are crucial for sustainable stone operations. Best practices include implementing closed-loop water recycling systems that capture and filter process water for reuse. These systems typically incorporate settling tanks and filtration units to remove stone particles and debris before recirculating the water back into the production process.

Regular monitoring of water quality and maintaining proper pH levels ensures optimal cutting and polishing performance while minimizing waste. Installing water meters at key points helps track usage patterns and identify potential leaks or inefficiencies. Modern stone fabrication facilities often employ automated systems that adjust water flow based on actual processing needs, reducing unnecessary consumption.

Rainwater harvesting systems can supplement traditional water sources, particularly in regions with consistent precipitation. Storage tanks should be properly sized based on facility needs and local rainfall patterns. Regular maintenance of collection systems, including gutters and filters, prevents contamination and ensures reliable water quality.

Additionally, implementing proper drainage systems and containment areas prevents environmental contamination while allowing for efficient water collection and treatment. This approach not only conserves water resources but also reduces operational costs and ensures compliance with environmental regulations.

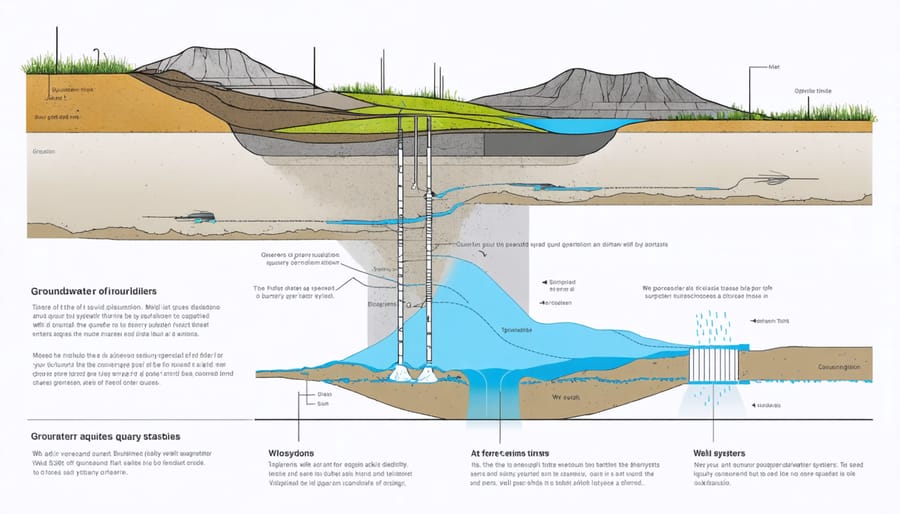

Groundwater Systems and Aquifers

Well Systems in Quarries

Well systems in quarries play a crucial role in water management and stone extraction operations. These engineered systems consist of strategically placed wells that serve multiple purposes, from dewatering operations to maintaining stable groundwater levels during quarrying activities.

Typically, a quarry well system includes both extraction and monitoring wells. Extraction wells pump out excess groundwater to create workable conditions, while monitoring wells track water table levels and quality. Modern quarry operations often implement automated pump systems that respond to real-time water level data, ensuring optimal working conditions while preserving local groundwater resources.

The design of these systems requires careful consideration of local hydrogeology, quarry depth, and production requirements. Wells are usually positioned around the quarry’s perimeter to create a cone of depression, effectively lowering the water table within the extraction area. This approach helps prevent flooding while minimizing impact on surrounding groundwater resources.

Maintenance of well systems involves regular inspection, water quality testing, and pump servicing to ensure reliable operation. Sustainable practices include water recycling systems that collect and treat pumped water for reuse in stone cutting and dust suppression, reducing environmental impact and operating costs.

Sustainable Extraction Practices

Maintaining groundwater balance during quarry operations requires careful planning and implementation of sustainable extraction practices. Modern quarries employ sophisticated monitoring systems to track water levels and ensure responsible usage throughout the extraction process. These systems include piezometers for measuring groundwater pressure and automated pumping stations that regulate water flow.

Quarry operators must carefully manage the balance between operational needs and environmental preservation. This involves implementing water recycling systems, creating settling ponds to filter and reuse process water, and establishing buffer zones around water bodies. Regular hydrogeological assessments help determine safe extraction rates that won’t deplete local aquifers.

Many quarries now incorporate rainwater harvesting systems and storage facilities to reduce their reliance on groundwater resources. This approach not only conserves natural water sources but also provides a reliable supply for operations during drier periods. Advanced water management techniques, such as controlled drainage systems and strategic placement of retention basins, help maintain natural groundwater levels while supporting efficient extraction operations.

Best practices also include regular monitoring of surrounding wells and water bodies to detect any potential impacts on local water resources, ensuring long-term sustainability of both the quarry operations and the surrounding ecosystem.

Atmospheric Water Storage

Humidity Control

Humidity control plays a crucial role in stone processing operations, directly impacting both the quality of the finished product and the efficiency of the manufacturing process. Atmospheric moisture, while less visible than other water sources, can significantly affect stone cutting, polishing, and storage environments. When humidity levels are too high, stone materials can become more difficult to process and may develop unwanted surface characteristics.

To maintain optimal conditions, modern stone processing facilities employ sophisticated climate control systems that monitor and regulate humidity levels. These systems typically maintain relative humidity between 45-60%, which provides the ideal environment for stone processing while preventing issues like mineral efflorescence or mold growth. Dehumidification equipment works in conjunction with ventilation systems to remove excess moisture from the air, particularly important in regions with naturally high humidity levels.

The controlled environment also helps protect cutting tools and machinery from moisture-related wear, extending their operational life and ensuring consistent cutting quality. Regular monitoring of humidity levels through digital sensors helps facility managers maintain these optimal conditions throughout the year, adjusting for seasonal variations in atmospheric moisture.

Rainwater Harvesting

Rainwater harvesting represents a sustainable approach to water management, particularly valuable in stone processing operations. This system captures and stores precipitation from rooftops, hardscapes, and other surfaces, providing a reliable water source for various applications. Modern harvesting systems typically include collection surfaces, gutters, filters, and storage tanks, enabling businesses to reduce their reliance on municipal water supplies.

In stone fabrication facilities, harvested rainwater can be effectively used for cutting, polishing, and cooling processes. A well-designed system can collect thousands of gallons during a single rainfall event, significantly offsetting operational water needs. This stored water proves especially valuable during dry seasons or in regions with water restrictions.

Implementation requires careful planning, including proper filtration systems to remove debris and contaminants, appropriate storage solutions, and distribution mechanisms. Many facilities incorporate UV treatment or basic filtration to ensure water quality meets processing requirements. The return on investment typically occurs within 2-5 years, making rainwater harvesting both environmentally responsible and economically sensible for stone industry operations.

Ice and Snow Storage

Seasonal Challenges

Winter poses unique challenges for water storage systems across different regions. As temperatures drop below freezing, surface water sources like lakes and rivers develop ice cover, affecting accessibility and operational procedures. This seasonal transition requires careful monitoring of water levels and infrastructure integrity.

During spring thaw, rapid temperature changes can lead to increased water volume from melting snow and ice, potentially overwhelming storage capacity. This phenomenon particularly affects regions with significant snowpack, where careful management of reservoirs and detention systems becomes crucial.

Storage facilities must be equipped with proper insulation and heating systems to prevent pipe freezing and structural damage. Regular maintenance checks during winter months help identify potential weak points before they become critical issues. Additionally, monitoring groundwater levels becomes more challenging when surface access points are frozen, requiring specialized equipment and procedures.

To maintain consistent water availability year-round, operators must plan for these seasonal variations, implementing appropriate storage solutions and backup systems that can withstand extreme temperature fluctuations.

Meltwater Management

Seasonal meltwater from snow and glaciers presents both opportunities and challenges for stone processing operations. This natural water source, typically available during spring and early summer months, can be effectively harnessed through proper management systems. Modern quarries and processing facilities often utilize retention ponds and storage tanks to capture and store meltwater during peak flow periods, ensuring a steady supply throughout drier seasons.

The key to successful meltwater management lies in implementing efficient filtration systems to remove sediments and impurities before use in cutting, polishing, or cooling operations. Many facilities incorporate settlement tanks and multi-stage filtration processes to achieve optimal water quality. This approach not only reduces operational costs but also promotes environmental sustainability by decreasing reliance on municipal water supplies.

However, meltwater management requires careful monitoring of seasonal variations and storage capacity planning to maintain consistent production schedules year-round. Facilities in regions with significant seasonal meltwater must also consider freeze protection measures during colder months.

Effective water storage management is crucial for sustainable stone operations. By understanding and properly managing the four major water sources – surface water, groundwater, atmospheric water, and biological water – operators can optimize their processes while minimizing environmental impact. Implementing closed-loop water recycling systems, regular monitoring of water quality, and proper storage infrastructure helps reduce water consumption and maintain operational efficiency. Additionally, incorporating modern filtration technology and scheduled maintenance routines ensures compliance with environmental regulations while maximizing water resource utilization. Stone facilities should develop comprehensive water management plans that account for seasonal variations and local water availability, ensuring long-term sustainability of their operations while protecting these vital natural resources.