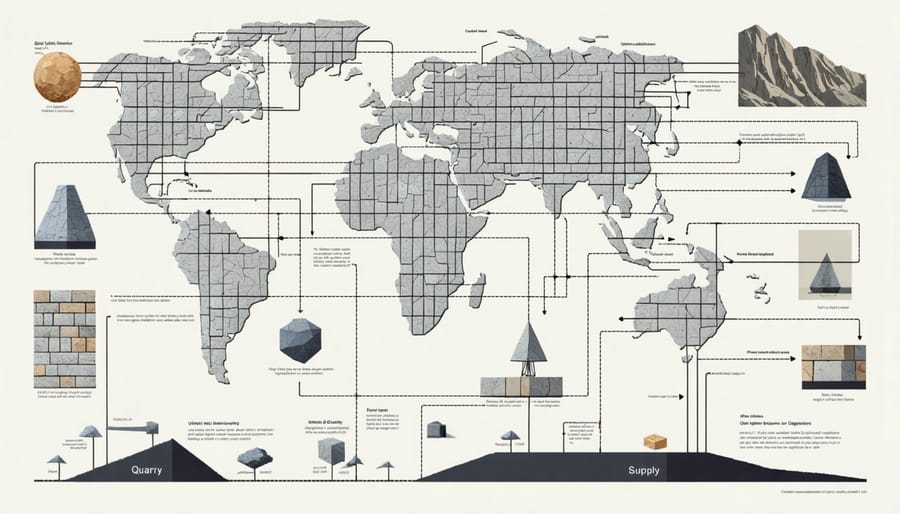

Natural stone stands as one of humanity’s most enduring building materials, transforming ordinary spaces into timeless masterpieces through its unique patterns, textures, and inherent durability. From the quarries of Italian marble to the rugged granite deposits of North America, the global natural stone supply chain represents a sophisticated network of extraction, processing, and distribution that powers a multi-billion dollar industry.

Understanding natural stone supply proves crucial for success in modern construction and design projects. Whether sourcing limestone for a historic restoration, selecting granite for a commercial development, or choosing marble for a luxury residential project, the journey from quarry to installation site involves critical decisions that impact cost, quality, and project timelines.

Today’s natural stone market combines centuries-old extraction techniques with cutting-edge technology, offering unprecedented access to diverse materials from around the world. Yet this accessibility brings new challenges in sustainability, quality control, and supply chain management that industry professionals must navigate carefully. Through strategic sourcing, proper material evaluation, and informed supplier selection, project leaders can harness the full potential of natural stone while managing costs and ensuring reliable supply for their ventures.

Global Quarry Operations and Market Dynamics

Major Stone Producing Regions

The global natural stone industry is characterized by distinct regional hubs, each renowned for specific types and qualities of stone. Italy’s Carrara region remains the world’s premier source of high-grade marble, producing the pristine white stone that has been coveted since Roman times. In India, the state of Rajasthan leads granite and sandstone production, with the Makrana belt specifically famous for its pure white marble used in iconic structures like the Taj Mahal.

Brazil has emerged as a powerhouse in granite extraction, with its quarries in Espírito Santo state offering an impressive variety of colors and patterns. China dominates the global market in terms of volume, particularly in granite and slate production, with major quarrying operations in Fujian and Shandong provinces.

Turkey’s stone industry centers around the Aegean region, known for its travertine deposits, particularly in Denizli, while also producing significant quantities of marble and limestone. In North America, Vermont leads U.S. marble production, while Georgia and Minnesota are notable for granite. Spain’s Alicante region is celebrated for its unique marble varieties, including the distinctive Crema Marfil.

These regions maintain their prominence through a combination of geological richness, advanced extraction technologies, and generations of stoneworking expertise. Each area’s unique geological conditions create stone varieties with distinct characteristics, making them suitable for specific architectural and design applications.

Market Forces Affecting Stone Availability

The natural stone market is influenced by a complex interplay of global economic factors and local industry dynamics. Supply and demand fluctuations can significantly impact stone availability and pricing, with market volatility in stone supply becoming increasingly common in recent years.

Quarry capacity and extraction rates play a crucial role in stone availability. When demand surges, especially during construction booms, quarries may struggle to maintain adequate production levels, leading to longer lead times and higher prices. Conversely, during economic downturns, reduced demand can result in excess inventory and more competitive pricing.

International trade policies and regulations also affect stone availability. Import tariffs, trade agreements, and environmental regulations can impact both the cost and accessibility of specific stone varieties. Transportation costs, particularly for heavy stone materials, fluctuate with fuel prices and shipping container availability.

Weather conditions and seasonal factors can affect quarry operations and transportation schedules. Extreme weather events or prolonged adverse conditions may temporarily halt extraction activities or delay shipments. Additionally, labor availability and skilled workforce shortages in quarrying regions can constrain production capacity.

Market preferences for particular stone types or finishes can create supply bottlenecks. When certain varieties become trendy in architectural design, demand may temporarily exceed available supply, affecting both pricing and delivery schedules.

Transportation and Distribution Networks

Shipping Routes and Logistics

Transportation of natural stone requires careful planning and coordination across multiple logistics channels. The choice of shipping method significantly impacts both delivery timelines and surging stone prices in today’s market. Most natural stone begins its journey via truck transport from quarries to processing facilities, followed by either container shipping or rail transport for longer distances.

Ocean freight remains the primary method for international stone shipments, with specialized containers designed to protect slabs and blocks during transit. These containers feature reinforced floors and securing systems to prevent movement and potential damage. The average transit time for overseas shipments ranges from 20 to 45 days, depending on the origin and destination ports.

For domestic distribution, trucking networks handle most deliveries, utilizing flatbed trucks for large slabs and enclosed trailers for cut-to-size pieces. Rail transport offers a cost-effective alternative for long-distance inland shipping, particularly for bulk orders, though it requires additional handling at rail terminals.

Key logistics considerations include:

– Load securing and protection against weather

– Insurance coverage during transit

– Customs clearance for international shipments

– Last-mile delivery coordination

– Storage facilities at major distribution points

Transport costs typically account for 15-30% of the final stone price, varying with fuel prices, distance, and handling requirements. To optimize costs, suppliers often consolidate shipments and maintain strategic distribution centers near major markets, balancing storage expenses against transportation efficiency.

Distribution Centers and Storage

Distribution centers play a vital role in the natural stone supply chain, serving as crucial intermediaries between quarries and end-users. These facilities typically maintain extensive inventories of various stone types, enabling quick response to market demands and reducing lead times for customers.

Modern stone distribution centers feature climate-controlled environments and specialized handling equipment to preserve the quality of stone materials. Large overhead cranes, forklifts with specialized attachments, and automated storage systems ensure safe material handling while minimizing damage risks.

Strategic locations near major transportation hubs allow distributors to optimize delivery routes and reduce shipping costs. Many centers maintain relationships with multiple quarries and suppliers, offering customers a diverse selection of stones from different global sources under one roof.

These facilities also provide value-added services such as quality inspection, custom cutting, and packaging. Professional storage teams carefully monitor inventory levels, track material movement, and maintain detailed documentation of stone characteristics and origins.

Most modern distribution centers utilize advanced inventory management systems to track stock levels, monitor material flow, and coordinate deliveries. This technology enables real-time inventory visibility and efficient order fulfillment, helping to prevent stockouts and ensure timely delivery to construction sites or fabrication facilities.

For industry professionals, these centers often serve as showrooms where clients can view stone samples and receive expert consultation on material selection, helping bridge the gap between quarry production and final application.

Supply Chain Challenges and Solutions

Lead Times and Availability

Lead times for natural stone supply can vary significantly depending on several key factors. Domestic stone typically requires 4-6 weeks from order to delivery, while imported materials may need 8-12 weeks or longer. These timeframes account for quarrying, cutting, finishing, and transportation.

Availability is influenced by quarry production schedules, seasonal variations, and current market demand. Popular stones may have longer wait times due to high demand, while specialty or rare stones might require extended lead times due to limited extraction periods or specific quarry conditions.

Several factors can impact delivery schedules:

– Quarry capacity and production volumes

– Processing facility workload

– Transportation logistics and shipping routes

– Customs clearance for imported stone

– Weather conditions affecting quarry operations

– Special finishing requirements

– Order volume and complexity

To ensure smooth project timelines, it’s recommended to:

– Plan orders well in advance

– Confirm stock availability for your specific requirements

– Consider alternative stones with shorter lead times

– Account for potential delays in project scheduling

– Maintain open communication with suppliers

Some suppliers maintain inventory of popular stones, which can significantly reduce lead times. However, for custom orders or large projects, early planning and clear communication with suppliers are essential to avoid delays and ensure successful project completion.

Quality Control Measures

Quality control in natural stone supply involves rigorous inspection processes and adherence to international standards throughout the supply chain. At the quarry level, blocks undergo initial assessment for structural integrity, color consistency, and mineral composition. Experts examine the stone for natural flaws, veining patterns, and potential weak points that could affect its performance.

During processing, manufacturers implement multiple inspection points to ensure slabs and finished products meet specifications. This includes dimensional accuracy checks, surface finish evaluation, and testing for physical properties such as density, water absorption, and flexural strength. Advanced technologies like ultrasonic testing and digital imaging help identify internal defects not visible to the naked eye.

Third-party certification bodies regularly audit facilities and test samples to verify compliance with industry standards such as ASTM International and European EN specifications. Documentation, including material test reports and certificates of conformity, accompanies stone products through the supply chain.

At the distribution level, warehouses maintain climate-controlled environments and proper storage practices to prevent material degradation. Before final delivery, products undergo one last quality inspection for shipping damage, matching against approved samples, and verification of finishing details.

Companies increasingly implement track-and-trace systems to monitor quality control measures across the entire supply chain, ensuring transparency and accountability from extraction to installation. This comprehensive approach helps maintain consistent product quality and reduces the risk of material failures in finished projects.

Risk Management Strategies

Effective risk management in natural stone supply requires a multi-faceted approach to ensure project continuity and cost stability. While getting the best stone prices is important, protecting your investment through strategic planning is equally crucial.

Diversifying supplier relationships stands as a primary strategy, establishing partnerships with multiple quarries and distributors across different geographical regions. This approach helps safeguard against regional disruptions and ensures consistent material availability.

Implementing robust quality control protocols at various checkpoints throughout the supply chain helps identify potential issues early. Regular material inspections, detailed documentation, and clear communication channels between suppliers, fabricators, and project managers are essential components of this process.

Weather-related delays and seasonal variations can significantly impact stone extraction and transportation. Planning orders with adequate lead times and maintaining buffer inventory when possible helps mitigate these risks. Additionally, securing proper insurance coverage specifically tailored to natural stone transportation and storage protects against potential losses.

Contract management plays a vital role in risk mitigation. Clear agreements should outline contingency plans, delivery schedules, and quality standards. Including force majeure clauses and specific remediation procedures helps protect all parties involved while ensuring project timelines remain on track.

Cost Implications for Projects

Understanding the construction cost impacts of natural stone supply is crucial for effective project planning. Several key factors influence the final price tag of stone materials, with transportation often accounting for 15-30% of total costs. Distance from quarry to project site, fuel prices, and delivery logistics all play significant roles in determining expenses.

Market demand fluctuations can cause substantial price variations throughout the year. Peak construction seasons typically see price increases of 10-20%, while off-peak periods may offer opportunities for cost savings. International trade conditions, including tariffs and exchange rates, further affect pricing for imported stones.

Quality and availability of specific stone types directly impact costs. Rare or highly sought-after varieties can command premium prices, while more abundant options generally remain more economical. Processing requirements, such as custom cutting or finishing, add another layer to the cost structure, potentially increasing expenses by 25-40%.

To manage costs effectively, project planners should consider:

– Ordering materials well in advance to secure better pricing

– Bundling orders to optimize transportation costs

– Maintaining flexibility in stone selection to take advantage of market opportunities

– Building relationships with reliable suppliers for potential volume discounts

– Including adequate contingency budgets for market fluctuations

Early planning and careful consideration of these supply chain factors can help prevent budget overruns and ensure successful project completion. Working with experienced suppliers who understand market dynamics can provide valuable insights into cost optimization strategies.

Natural stone supply involves a complex yet manageable process that rewards careful planning and informed decision-making. By understanding the key factors of sourcing, transportation, and quality control, you can ensure successful procurement of the perfect stone for your project. Remember to work with reputable suppliers, factor in lead times and seasonal variations, and always request samples before making major purchases. Consider sustainability practices and certifications when selecting your supplier, and don’t hesitate to ask about their quarry operations and material handling procedures. Whether you’re planning a small residential project or a large commercial development, proper research and partnership with experienced professionals will help you navigate the natural stone supply chain effectively. With these insights in mind, you’re well-equipped to make informed decisions and achieve stunning results in your stone applications.