The convergence of artificial intelligence and Industry 4.0 is fundamentally reshaping manufacturing, decision-making, and value creation across global industries. As we stand at the threshold of this technological revolution, AI-powered systems are transforming traditional production methods into smart, autonomous operations that learn, adapt, and optimize in real-time. From predictive maintenance and quality control to supply chain optimization and personalized manufacturing, AI technologies are driving unprecedented levels of efficiency and innovation.

This transformation extends beyond mere automation, creating entirely new business models and operational paradigms. Machine learning algorithms now analyze vast datasets to predict market trends, optimize resource allocation, and enhance product design, while advanced robotics and AI-enabled systems collaborate seamlessly with human workers. In the construction and design sectors specifically, AI is revolutionizing everything from material selection and structural analysis to project planning and execution.

For industry professionals and decision-makers, understanding the implications of AI in the Fourth Industrial Revolution isn’t just about staying competitive—it’s about reimagining the future of their enterprises. This technological convergence offers unprecedented opportunities for those ready to embrace smart manufacturing, data-driven decision-making, and AI-enhanced productivity solutions.

The Fourth Industrial Revolution Meets Natural Stone

Digital Transformation in Stone Processing

The integration of artificial intelligence and Industry 4.0 technologies is rapidly transforming stone processing into a highly efficient, data-driven operation. Advanced robotics and AI-powered cutting systems now analyze stone slabs in real-time, optimizing cut patterns to maximize material yield while minimizing waste. Computer vision systems equipped with deep learning algorithms can detect imperfections and variations in stone patterns, ensuring consistent quality across production batches.

Digital twins of processing equipment enable predictive maintenance and real-time monitoring, reducing downtime and extending machine life. Smart sensors throughout the production line collect data on everything from blade wear to water pressure, allowing for automated adjustments that maintain optimal cutting conditions.

These technological advances have resulted in significant improvements in production efficiency, with some facilities reporting up to 30% reduction in material waste and 40% increase in throughput. The integration of AI has also enhanced worker safety by automating dangerous tasks and providing early warning systems for potential equipment failures.

Smart Integration Systems

In modern stone fabrication facilities, Internet of Things (IoT) devices and connected systems form an intricate network that revolutionizes production efficiency and quality control. Smart sensors continuously monitor machine performance, material flow, and environmental conditions, providing real-time data that helps optimize operations and prevent costly downtime.

These integrated systems enable seamless communication between various production stages, from initial slab scanning to final cutting and polishing. Digital twins create virtual representations of the production line, allowing managers to simulate different scenarios and make data-driven decisions. Advanced tracking systems monitor stone pieces throughout the fabrication process, ensuring precise inventory management and streamlined workflow.

Connected systems also enhance maintenance procedures through predictive analytics. By analyzing performance patterns, the system can forecast potential equipment failures before they occur, scheduling maintenance during off-peak hours. This proactive approach significantly reduces unexpected breakdowns and maintains consistent production quality.

Cloud-based platforms integrate these various components, providing accessibility to authorized personnel from anywhere. This connectivity enables remote monitoring, troubleshooting, and real-time collaboration between design teams, fabricators, and clients, creating a more efficient and responsive production environment.

AI-Powered Quality Control and Inspection

Computer Vision for Defect Detection

Computer vision technology has revolutionized defect detection in the stone industry, bringing unprecedented accuracy and efficiency to quality control processes. Through sophisticated AI-powered quality inspection systems, manufacturers can now detect even the smallest imperfections that might be missed by human inspectors.

These systems use high-resolution cameras and advanced algorithms to analyze stone surfaces in real-time, identifying defects such as cracks, fissures, color variations, and structural inconsistencies. The AI models are trained on thousands of images of both flawless and defective stone samples, enabling them to distinguish between natural variations and genuine flaws with remarkable precision.

The technology operates by creating detailed surface maps of stone slabs, comparing them against established quality parameters. When a defect is detected, the system immediately flags the area and categorizes the type of imperfection, allowing for quick decision-making in the production process. This automated inspection process not only increases throughput but also ensures consistent quality standards across all stone products.

For fabricators and manufacturers, this translates to reduced waste, lower operational costs, and higher customer satisfaction. The system’s ability to learn and improve over time means it becomes increasingly accurate at identifying defects specific to different stone types and finishing processes, making it an invaluable tool in modern stone processing facilities.

Automated Grading Systems

Artificial Intelligence has revolutionized quality control in the natural stone industry through advanced automated grading systems. These systems employ sophisticated computer vision and machine learning algorithms to assess stone slabs with unprecedented accuracy and consistency. Unlike human inspectors who may experience fatigue or subjective bias, AI-powered grading systems operate 24/7 with unwavering precision.

Modern stone grading systems utilize high-resolution cameras and sensors to capture detailed images of stone surfaces, analyzing characteristics such as color variation, veining patterns, structural integrity, and potential defects. The AI algorithms process this data in real-time, categorizing stones based on predefined quality parameters and market standards.

These systems can detect microscopic fissures, irregular patterns, and color inconsistencies that might be challenging for the human eye to identify. By maintaining a database of thousands of stone samples, the AI continuously learns and improves its classification accuracy, adapting to new stone varieties and quality standards as they emerge.

The implementation of automated grading systems has significantly reduced processing time and improved inventory management. Fabricators can now quickly sort and grade large quantities of stone, ensuring consistent quality standards across their product lines. This technology has also enabled more accurate pricing strategies based on objective quality assessments, benefiting both suppliers and customers in the natural stone market.

Predictive Maintenance and Resource Optimization

Machine Learning for Equipment Maintenance

Machine learning algorithms are revolutionizing equipment maintenance in stone processing facilities by predicting potential failures before they occur. These AI-powered systems continuously monitor vital equipment parameters such as vibration patterns, temperature variations, and power consumption to detect early warning signs of mechanical issues.

By analyzing historical maintenance data and real-time sensor readings, predictive maintenance systems can accurately forecast when specific components might fail or require servicing. This proactive approach helps facility managers schedule maintenance activities during planned downtimes, significantly reducing unexpected breakdowns and costly production interruptions.

For example, smart sensors installed on stone cutting machines can detect subtle changes in blade performance, allowing operators to replace worn components before they affect cut quality. Similarly, AI systems monitor CNC machine spindle bearings, hydraulic systems, and conveyor belts, ensuring optimal performance and extending equipment lifespan.

The implementation of these systems has shown remarkable results across the industry, with some facilities reporting up to 30% reduction in maintenance costs and 25% decrease in unexpected downtime. Additionally, predictive maintenance helps optimize spare parts inventory management, ensuring critical components are available when needed while minimizing storage costs.

Resource Management and Waste Reduction

Artificial Intelligence is revolutionizing resource management and waste reduction in industrial processes through sophisticated optimization algorithms and predictive analytics. By leveraging machine learning capabilities, AI systems can accurately predict material requirements, optimize cutting patterns, and minimize waste in manufacturing processes. These waste reduction technologies are particularly impactful in industries dealing with valuable raw materials.

Smart AI algorithms analyze historical production data, current inventory levels, and upcoming orders to determine the most efficient use of resources. In stone processing, for example, AI systems can calculate optimal cutting patterns that maximize material utilization while maintaining quality standards. This not only reduces waste but also leads to significant cost savings and environmental benefits.

Real-time monitoring systems powered by AI can detect inefficiencies in production processes, automatically adjusting parameters to minimize material waste and energy consumption. The technology also enables predictive maintenance scheduling, preventing equipment failures that could result in material waste and production delays.

Through continuous learning and optimization, AI systems are helping industries achieve unprecedented levels of resource efficiency, contributing to both environmental sustainability and improved profitability in the fourth industrial revolution.

Design and Visualization Innovations

AI-Assisted Design Tools

AI-powered design tools are revolutionizing how professionals approach stone selection and implementation in modern architecture. These intelligent systems combine advanced pattern recognition with sophisticated modeling capabilities, enabling architects and designers to visualize and optimize their projects with unprecedented accuracy. By leveraging smart stone technologies, designers can now instantly generate multiple layout options, predict material requirements, and evaluate aesthetic combinations before making physical commitments.

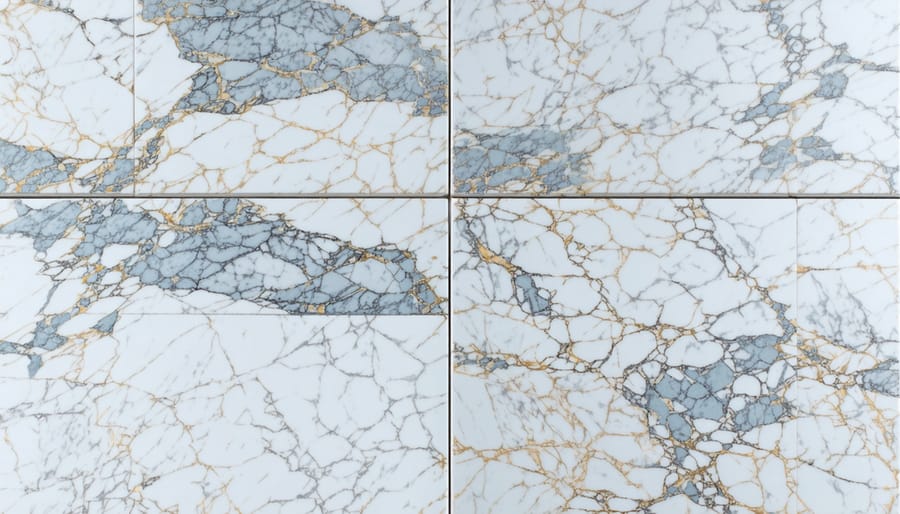

These tools excel at analyzing natural stone patterns, veining, and color variations to suggest optimal placement and matching across large surfaces. Machine learning algorithms can identify complementary stone types, forecast visual continuity in book-matched installations, and even predict how different finishing techniques will affect the final appearance.

For fabricators, AI design assistants streamline the transition from concept to production by automatically generating cutting patterns that maximize material efficiency while maintaining design integrity. These systems can also simulate how stone materials will age and weather over time, helping professionals make more informed decisions about durability and maintenance requirements.

The integration of virtual and augmented reality features allows clients to experience their stone selections in photorealistic environments, significantly reducing the risk of costly revisions and ensuring higher customer satisfaction.

Virtual and Augmented Reality Applications

Virtual and augmented reality technologies are revolutionizing the way professionals and clients interact with natural stone materials. Advanced VR applications now enable architects and designers to visualize stone patterns, textures, and finishes in immersive 3D environments before making physical selections. This technology allows for virtual walkthroughs of spaces featuring different stone options, significantly reducing decision-making time and potential costly mistakes.

AR applications have become particularly valuable in stone selection and placement visualization. Using mobile devices or AR headsets, professionals can overlay virtual stone samples onto existing spaces, helping clients understand how different materials will look in their actual environment. These tools can simulate various lighting conditions, showcase different finish options, and demonstrate how stone patterns will flow across surfaces.

The integration of AI with VR/AR technology further enhances these capabilities by offering intelligent suggestions based on design preferences, budget constraints, and practical considerations. Machine learning algorithms can analyze thousands of stone patterns and installations to recommend optimal material choices and layout configurations.

Real-time collaboration features within these platforms allow multiple stakeholders to participate in virtual design sessions simultaneously, regardless of their physical location. This capability has proven especially valuable during recent global challenges, enabling projects to progress without interruption.

Future Implications and Industry Impact

The convergence of AI and Industry 4.0 technologies is set to revolutionize the natural stone industry in profound ways over the next decade. Smart factories equipped with AI-driven automation will become the norm, enabling stone processing facilities to operate with minimal human intervention while maintaining exceptional quality standards.

Predictive maintenance systems will evolve to detect potential equipment failures before they occur, significantly reducing downtime and maintenance costs. Advanced AI algorithms will optimize cutting patterns and material utilization, potentially reducing waste by up to 30% compared to current practices.

Digital twins of production facilities will become more sophisticated, allowing companies to simulate and optimize their operations in real-time. This technology will enable manufacturers to test new processes and configurations virtually before implementing them on the factory floor.

The integration of AI with augmented reality (AR) will transform installation and maintenance procedures, providing workers with real-time guidance and reducing errors. Customer experience will also evolve through AI-powered visualization tools that offer photorealistic previews of stone applications in specific spaces.

Supply chain management will become more resilient through AI-driven forecasting and inventory optimization. These systems will adapt to market fluctuations and environmental factors, ensuring steady material availability while minimizing storage costs.

Perhaps most significantly, AI will enable new levels of customization in stone products. Machine learning algorithms will analyze customer preferences and architectural trends to suggest innovative design possibilities, while automated manufacturing systems will make custom productions more economically viable.

These advancements will likely lead to increased sustainability in the industry, as AI optimization reduces waste, energy consumption, and transportation costs while maximizing resource utilization.

The convergence of artificial intelligence and Industry 4.0 technologies is fundamentally transforming the natural stone industry, ushering in an era of unprecedented efficiency and innovation. As we’ve explored, AI-powered solutions are revolutionizing everything from quarry operations to final installation, with smart automation and predictive analytics leading the charge.

Looking ahead, we can expect even more sophisticated applications of AI in stone processing, including advanced robotics for complex cutting patterns, real-time quality control systems, and integrated design platforms that seamlessly connect architects, fabricators, and clients. The continued development of machine learning algorithms will further enhance material optimization and waste reduction, making stone processing more sustainable and cost-effective.

However, success in this new era requires a balanced approach. While embracing technological advancement, industry professionals must maintain their craft expertise while developing new digital skills. Organizations that can effectively combine traditional stoneworking knowledge with AI capabilities will be best positioned to thrive in this evolving landscape.

As we move forward, the integration of AI in the stone industry will continue to accelerate, creating new opportunities for innovation, efficiency, and creative expression in architectural and design applications.