Cement manufacturing stands as one of humanity’s most transformative industrial processes, converting abundant limestone and clay into the literal foundation of modern civilization. This complex choreography of chemistry, engineering, and precision control produces over 4 billion tons of cement annually, enabling everything from suburban homes to soaring skyscrapers.

The journey from raw material to finished cement represents a masterpiece of industrial innovation, refined over two centuries since Joseph Aspdin patented Portland cement in 1824. Today’s manufacturing processes combine time-tested principles with cutting-edge technology, optimizing both quality and sustainability at every step.

Yet beneath this seemingly straightforward process lies an intricate balance of temperatures reaching 1,450°C (2,642°F), precisely controlled chemical reactions, and rigorous quality standards that ensure every batch meets exacting specifications. Understanding these processes is crucial not only for industry professionals but also for addressing modern challenges of carbon emissions and environmental impact.

As global construction demands continue to rise, innovative manufacturing techniques are emerging to create more sustainable cement while maintaining the strength and durability that have made it indispensable to human progress. This article explores the essential steps, critical controls, and evolving technologies that define modern cement production, from quarry extraction to final packaging.

Raw Material Selection and Preparation

Essential Raw Materials

Limestone serves as the primary raw material in cement manufacturing, typically comprising 70-80% of the total raw material mix. This sedimentary rock, rich in calcium carbonate (CaCO3), provides the essential calcium oxide needed for cement formation. High-quality limestone deposits are carefully selected for their chemical composition and purity levels.

Clay materials make up the second most crucial component, contributing about 20-25% of the raw mix. Clay provides the necessary silica, alumina, and iron oxide compounds that enable the formation of cement clinker. The specific type of clay used can vary by region and availability, but common varieties include shale, slate, and mudstone.

Additional materials, known as corrective ingredients, are often added in smaller quantities to achieve the desired chemical composition. These may include bauxite for aluminum content, iron ore for iron oxide, or sand for silica adjustment. The precise proportioning of these materials is critical for producing cement with consistent quality and performance characteristics.

Raw materials must meet strict quality standards regarding their chemical composition, moisture content, and physical properties. Modern cement plants often source materials from multiple quarries to maintain consistent supply and quality control. These materials are regularly tested in laboratories to ensure they meet manufacturing specifications before entering the production process.

Material Processing and Mixing

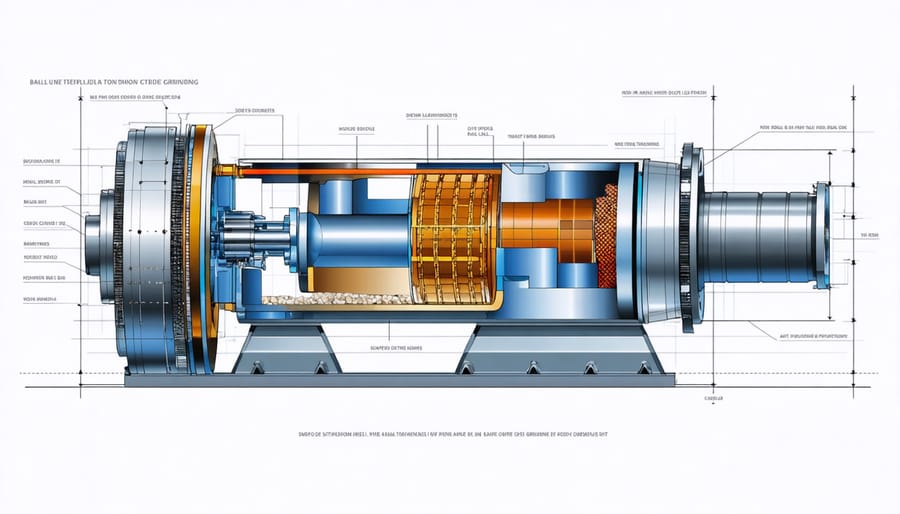

The raw material processing phase begins with crushing large chunks of limestone, clay, and other materials into manageable sizes. Primary crushers reduce raw materials to pieces roughly 6 inches in diameter, while secondary crushers further decrease them to about 3 inches. These materials then move to ball mills or vertical roller mills, where they’re ground into a fine powder known as raw meal.

The grinding process is crucial for achieving the right particle size distribution, which directly affects the cement’s quality. Modern facilities use sophisticated analyzer systems to continuously monitor and adjust the grinding process, ensuring consistent material fineness.

After grinding, the raw materials are carefully proportioned according to the desired cement composition. This typically involves 80% limestone, 15% clay or shale, and 5% other materials like iron ore or sand. Computer-controlled systems manage the proportioning process, maintaining precise ratios that determine the final cement properties.

The mixed materials are then homogenized in large blending silos. These silos use compressed air or mechanical systems to create a uniform mixture, eliminating any chemical or physical variations that could affect the finished product’s quality. This homogenization step is essential for producing consistent, high-quality cement.

The Clinker Production Process

Pre-heating and Calcination

Pre-heating and calcination represent crucial manufacturing processes in cement production, where raw materials undergo significant thermal and chemical transformations. The process begins in the pre-heater tower, where the raw meal is exposed to hot gases flowing counter-currently through a series of cyclones. This efficient heat exchange gradually raises the material’s temperature from ambient to approximately 850°C (1,562°F).

During pre-heating, the raw material begins to undergo initial chemical changes. Moisture evaporates, and clay minerals start to break down. As the material continues its journey, it enters the calciner, where temperatures reach about 900°C (1,652°F). Here, limestone (calcium carbonate) decomposes into calcium oxide and carbon dioxide in a process called calcination.

The chemical equation for this reaction is:

CaCO₃ → CaO + CO₂

This endothermic reaction requires significant energy input and accounts for about 60% of the total energy consumption in cement production. Modern cement plants often incorporate calciners with advanced designs that optimize fuel efficiency and reduce emissions. Some facilities utilize alternative fuels during this stage to minimize environmental impact while maintaining process effectiveness.

The pre-heated and calcined material, now called hot meal, exhibits different physical and chemical properties from the raw meal. It becomes more reactive and ready for the subsequent clinkerization process in the rotary kiln. The efficiency of this stage directly influences the quality of the final cement product and the overall energy consumption of the plant.

Rotary Kiln Operations

The rotary kiln represents the heart of the cement manufacturing process, where raw materials transform into clinker through precise thermal processing. This cylindrical steel chamber, typically 60-90 meters in length and 3-4 meters in diameter, rotates slowly while maintaining temperatures reaching up to 1450°C (2642°F).

As materials travel through the kiln, they undergo several crucial chemical reactions. The process begins in the preheating zone, where temperatures range from 800-1000°C, driving off remaining moisture and initiating the breakdown of calcium carbonate. Moving deeper into the kiln, materials enter the calcination zone, where limestone decomposes into calcium oxide and carbon dioxide at approximately 900°C.

The most critical transformation occurs in the burning zone, where temperatures peak at 1450°C. Here, calcium oxide reacts with silica, alumina, and iron oxide to form clinker minerals: alite, belite, aluminate, and ferrite. These compounds give cement its characteristic strength-building properties when mixed with water.

The kiln’s slight inclination (3-4 degrees) and rotation (1-4 revolutions per minute) ensure materials move steadily through each temperature zone. Modern kilns feature sophisticated monitoring systems that control fuel consumption, rotation speed, and temperature profiles to optimize clinker formation while minimizing energy use.

After formation, the hot clinker enters the cooling zone, where carefully controlled cooling preserves the desired crystal structure. Rapid cooling helps maintain the reactive potential of clinker minerals, crucial for cement’s eventual performance in concrete.

The entire process requires precise control of various parameters:

– Temperature profile maintenance

– Oxygen levels for proper combustion

– Material feed rate

– Rotation speed

– Cooling rate

Modern rotary kilns often incorporate alternative fuel systems and heat recovery mechanisms to improve energy efficiency and reduce environmental impact, making this crucial process more sustainable while maintaining product quality.

Cooling and Storage

After exiting the kiln at temperatures around 1,000°C (1,832°F), the cement clinker requires careful cooling and storage procedures to ensure optimal quality and usability. The cooling process typically employs sophisticated clinker coolers, most commonly grate coolers, which serve dual purposes: reducing clinker temperature and recovering valuable heat energy.

The hot clinker first passes through the cooling chamber, where controlled air flows rapidly decrease its temperature to approximately 100°C (212°F). This rapid cooling is crucial for preserving the desired mineralogical composition of the clinker, directly impacting the final cement quality. The recovered heat from this process is typically redirected back to the kiln system, improving overall energy efficiency.

Once cooled, the clinker is transported to storage silos using conveyor systems or pneumatic methods. These storage facilities are designed to protect the material from moisture and contamination while maintaining proper temperature conditions. The clinker can be stored for extended periods without significant quality degradation, providing manufacturing flexibility and consistent supply capability.

Modern storage facilities are equipped with level sensors, temperature monitors, and automated extraction systems to ensure proper inventory management and material handling. Before final processing, the stored clinker undergoes quality checks to verify its chemical composition and physical properties remain within specifications.

This intermediate storage phase also allows manufacturers to blend different clinker batches if needed, ensuring consistent quality in the final cement product. The careful management of cooling and storage operations is essential for maintaining product quality and manufacturing efficiency while reducing energy consumption through heat recovery systems.

Final Processing and Quality Control

Grinding and Blending

The final grinding and blending stage is crucial in determining the cement’s ultimate performance characteristics. After the clinker cools, it enters industrial-scale grinding mills where it’s reduced to an extremely fine powder. During this process, gypsum is added in carefully controlled amounts, typically 3-5% by weight, to regulate the cement’s setting time and prevent flash setting.

Modern cement plants use sophisticated ball mills or vertical roller mills for this operation. These mills contain thousands of steel balls or rollers that tumble and crush the clinker and additives together, producing particles predominantly sized between 3 and 30 microns. The fineness of the grinding significantly impacts the cement’s strength development and workability.

Besides gypsum, manufacturers may incorporate other supplementary cementitious materials (SCMs) during this stage. Common additions include fly ash, slag, limestone, and pozzolanic materials, which can enhance specific properties of the finished cement while reducing its carbon footprint. The exact blend depends on the intended application and local building codes.

Quality control is paramount during grinding and blending. Advanced particle size analyzers continuously monitor the cement’s fineness, while automated systems adjust the grinding parameters to maintain consistency. The specific surface area of the finished cement, measured in square meters per kilogram (Blaine fineness), is carefully controlled to meet product specifications.

After grinding, the cement powder moves to storage silos through pneumatic conveyors. These silos are equipped with air pad systems that prevent the cement from compacting and maintain its free-flowing properties. Before dispatch, each batch undergoes final quality testing to ensure it meets all relevant standards and performance criteria. The finished product is then packaged in bags or prepared for bulk transport to construction sites and concrete plants.

Quality Testing and Standards

Quality testing in cement manufacturing involves rigorous procedures to ensure the final product meets industry standards and specifications. Modern quality control systems utilize advanced technology to monitor and test cement at various production stages.

Key testing parameters include chemical composition, fineness, setting time, and compressive strength. Chemical analysis ensures proper proportions of calcium, silicon, aluminum, and iron compounds. Fineness testing measures particle size distribution, which affects cement’s reactivity and strength development. Setting time tests determine how quickly cement hardens when mixed with water, crucial for construction scheduling.

The industry follows standardized testing protocols established by organizations like ASTM International and European Standards (EN). These standards specify minimum requirements for different cement types and grades. Common tests include:

– Compression strength testing at 3, 7, and 28 days

– Soundness testing to measure volume stability

– Heat of hydration measurements

– Alkali content analysis

– Air content evaluation

Quality assurance laboratories regularly sample cement throughout production. Each batch undergoes multiple tests before release for distribution. Modern facilities employ automated testing equipment and computerized data analysis to maintain consistent quality.

Environmental testing has become increasingly important, measuring emissions and ensuring compliance with environmental regulations. This includes monitoring dust particles, CO2 emissions, and other pollutants.

Documentation and traceability are essential components of quality control. Manufacturers maintain detailed records of test results, production parameters, and raw material sources. This documentation helps identify and resolve quality issues while ensuring regulatory compliance and customer satisfaction.

Environmental Considerations and Modern Innovations

The cement industry faces significant environmental challenges, primarily due to its substantial carbon footprint and resource consumption. Traditional cement production accounts for approximately 8% of global CO2 emissions, driving the sector to embrace innovative solutions in modern manufacturing facilities.

Leading manufacturers are implementing several key strategies to reduce environmental impact. Carbon capture and storage (CCS) technology is being integrated into production lines, allowing facilities to trap and store CO2 emissions before they enter the atmosphere. Alternative fuel sources, such as biomass and waste-derived fuels, are replacing traditional fossil fuels in kilns, significantly reducing carbon emissions.

The development of low-carbon cement varieties represents another crucial innovation. These include blended cements that incorporate supplementary cementitious materials (SCMs) like fly ash, slag, and natural pozzolans, reducing the clinker content while maintaining structural integrity. Some manufacturers are also experimenting with novel binding materials that require lower firing temperatures and produce fewer emissions.

Water conservation has become a priority in sustainable manufacturing practices, with closed-loop water systems and advanced filtration technology minimizing waste and environmental impact. Energy efficiency improvements, including heat recovery systems and advanced grinding technologies, further reduce the environmental footprint of cement production.

Emerging technologies like artificial intelligence and machine learning are optimizing production processes, reducing waste, and improving energy efficiency. These smart systems can predict maintenance needs, adjust operating parameters in real-time, and ensure optimal resource utilization throughout the manufacturing process.

The industry is also exploring carbon-neutral cement alternatives, including those that absorb CO2 during curing, potentially transforming cement from a carbon source to a carbon sink. These innovations, combined with strict environmental regulations and growing market demand for sustainable products, are reshaping the future of cement manufacturing.

Cement manufacturing continues to evolve with technological advancements and growing environmental consciousness. The traditional process, while well-established, is being enhanced with innovative solutions to reduce carbon emissions and improve energy efficiency. Modern plants increasingly adopt alternative fuels, waste heat recovery systems, and advanced grinding technologies to optimize production while minimizing environmental impact.

Looking ahead, the industry faces both challenges and opportunities. The push towards sustainable construction has sparked research into novel cement formulations with lower carbon footprints. Emerging technologies like carbon capture and storage show promise in reducing the industry’s environmental impact, while digitalization and automation are streamlining operations and improving quality control.

The future of cement manufacturing will likely focus on balancing production efficiency with environmental responsibility. As global construction demands continue to rise, manufacturers are investing in smart technologies and green innovations to meet these needs sustainably. This transformation ensures that cement production remains both economically viable and environmentally conscious, setting new standards for the construction industry’s future.