Transform your quartz surfaces into gleaming masterpieces with professional-grade polishing products engineered specifically for this resilient engineered stone. Modern quartz polishing compounds combine diamond abrasives and specialized polymers to restore, enhance, and protect your surfaces while maintaining their natural brilliance and structural integrity.

From kitchen countertops to commercial installations, proper polishing not only elevates aesthetic appeal but also extends the material’s longevity by creating a protective barrier against daily wear. Leading manufacturers now offer complete polishing systems that progress from initial restoration through final buffing, each step calibrated to work with quartz’s unique molecular structure.

Understanding the distinction between products designed for natural stone versus engineered quartz is crucial – using the wrong compounds can damage your surfaces irreparably. Professional-grade quartz polishing products typically include pH-neutral formulations that won’t compromise the resin binders integral to quartz surfaces, while still delivering the deep luster and clarity that defines well-maintained stone.

Whether you’re a homeowner maintaining daily beauty or a contractor handling large-scale installations, selecting the right quartz polishing products ensures optimal results and long-term protection for these significant investments.

Understanding Quartz Surface Types and Their Polishing Needs

Natural vs. Engineered Quartz

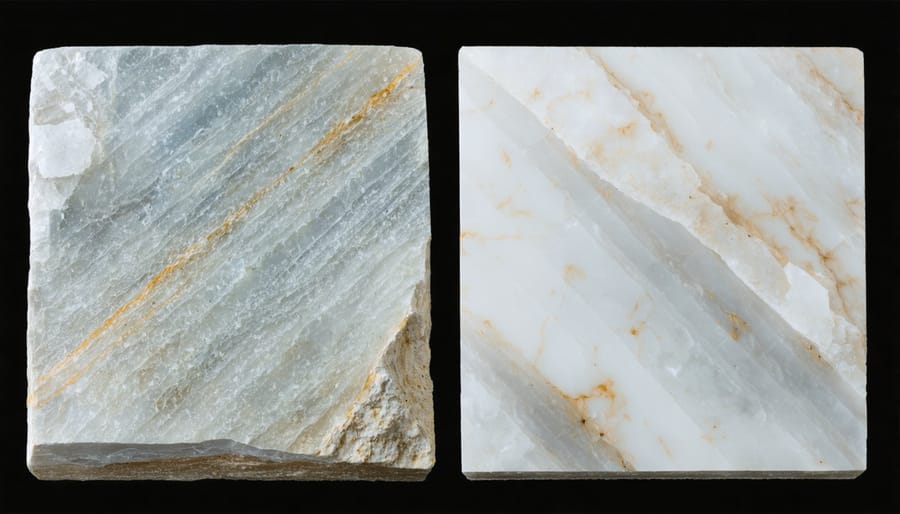

Natural and engineered quartz surfaces require distinctly different polishing approaches due to their unique composition and structure. Natural quartz, being formed through geological processes, typically has varying mineral concentrations and natural fissures that demand a more nuanced polishing technique. These surfaces often need a progressive approach, starting with coarser diamond pads and gradually moving to finer grits.

Engineered quartz, composed of approximately 93% natural quartz mixed with resins and pigments, generally requires less aggressive polishing methods. The manufactured uniformity of these surfaces means they typically maintain their shine longer and can be restored using finer polishing compounds from the start. However, the resin content in engineered quartz makes it more sensitive to certain chemicals and excessive heat during polishing.

For natural quartz, polishing products should focus on penetrating the stone’s natural structure, while engineered quartz products need to work with the resin-based surface without compromising its integrity. Temperature control during polishing is particularly crucial for engineered quartz to prevent resin damage, whereas natural quartz can generally withstand more aggressive polishing temperatures.

Signs Your Quartz Needs Polishing

Recognizing when your quartz surface needs polishing is crucial for maintaining its pristine appearance. The most obvious sign is a visible loss of shine, where the surface appears dull or matte compared to its original lustrous finish. You might notice light no longer reflects off the surface as brilliantly as it once did. Another common indicator is the presence of etching marks, which appear as dull spots or slight depressions in the surface, often caused by acidic substances.

If you observe fine scratches that catch the light at certain angles, or feel rough patches when running your hand across the surface, these are clear signals that polishing is necessary. In some cases, you may need to repair damaged quartz surfaces before polishing if the wear is significant. Water spots that don’t wipe away easily and stubborn stains that seem to have penetrated the surface are additional indicators that your quartz needs attention.

Regular inspection under good lighting can help you spot these signs early, making the polishing process more effective and preventing the need for more intensive restoration work.

Essential Quartz Polishing Products

Mechanical Polishing Tools

Mechanical polishing tools form the backbone of professional quartz surface finishing. Variable-speed angle grinders equipped with diamond polishing pads are the industry standard, offering precise control and consistent results across large surfaces. These machines typically operate between 2,000 and 4,000 RPM, allowing operators to adjust speeds based on the specific requirements of each project.

Handheld polishers come in both wet and dry varieties, with wet polishers being preferred for dust control and superior cooling during intensive work. Most professional-grade machines feature water feed systems that deliver a controlled flow directly to the polishing surface, preventing overheating and extending pad life.

For larger commercial projects, walk-behind floor polishers provide efficient coverage of expansive quartz surfaces. These machines typically feature multiple rotating heads and built-in water distribution systems, making them ideal for maintaining consistent pressure and achieving uniform results across large areas.

Essential attachments include progressive grit diamond pads, typically starting at 50-grit for heavy restoration work and advancing through to 3000-grit for final polish. Velcro-backed pads offer quick changes between grits, while rigid backing plates ensure even pressure distribution. Specialized edge tools and small-diameter pads allow for detailed work in corners and along vertical surfaces, ensuring comprehensive coverage in complex installations.

Regular maintenance of these tools, including proper cleaning and storage of diamond pads, helps ensure optimal performance and longevity of both the equipment and the finished surface.

Chemical Polishing Compounds

Chemical polishing compounds play a crucial role in achieving a professional finish on quartz surfaces. These compounds come in various formulations, each designed for specific applications and stages of the polishing process.

For initial polishing, diamond-based compounds ranging from 50 to 3000 grit are commonly used. These aggressive compounds effectively remove deep scratches and surface imperfections. Medium-grit compounds, typically containing aluminum oxide or cerium oxide, are perfect for intermediate polishing stages and help to clean without harsh chemicals while achieving a smooth surface.

Fine polishing compounds, often containing tin oxide or rare earth elements, are used in the final stages to achieve that mirror-like finish. These compounds are available in paste, liquid, or powder form, each offering distinct advantages. Paste compounds are ideal for vertical surfaces, while liquid formulations work well with mechanical polishers.

When selecting a polishing compound, consider factors like the quartz’s hardness, existing surface condition, and desired finish. Water-based compounds are increasingly popular due to their eco-friendly nature and easier cleanup. For best results, always follow manufacturer guidelines regarding compound progression and application techniques, and ensure proper safety measures are in place during use.

Maintenance Products

Regular maintenance is crucial for preserving your quartz surfaces’ brilliance, and using the right products makes all the difference. For daily cleaning, pH-neutral stone cleaners are essential, as they effectively remove surface dirt without damaging the stone’s finish. These gentle cleaners are specifically formulated to maintain quartz’s natural luster while preventing buildup that can dull its appearance over time.

Weekly maintenance should include a specialized quartz polish that enhances shine and provides a protective layer against stains and etching. Look for products containing mild conditioning agents that replenish the stone’s natural properties while adding resistance to fingerprints and water spots. Many manufacturers offer spray-and-wipe formulations that make the process quick and effortless.

For optimal results, pair these cleaning products with microfiber cloths rather than abrasive materials. The soft fibers effectively trap dirt particles without scratching the surface. Some maintenance products also contain UV inhibitors, which help prevent yellowing and discoloration in areas exposed to sunlight.

Consider incorporating a stone sealer into your maintenance routine every 12-18 months, even though quartz is naturally less porous than other stones. This extra layer of protection helps maintain the surface’s resistance to stains and ensures your polishing efforts last longer. Always test new products on a small, inconspicuous area first to ensure compatibility with your specific quartz surface.

Professional Polishing Techniques

Surface Preparation

Proper surface preparation is crucial for achieving optimal polishing results on quartz surfaces. Begin by thoroughly cleaning the surface using a pH-neutral stone cleaner to remove any dirt, grime, or existing sealers. Wipe the area with a clean, lint-free cloth and allow it to dry completely.

Inspect the surface carefully for any chips, cracks, or deep scratches. These imperfections should be addressed before polishing begins, as they can affect the final outcome. For minor scratches, start with a lower-grit diamond pad to level the surface.

Remove all items from the workspace and protect surrounding areas with plastic sheeting or painter’s tape. Ensure proper ventilation in the area and wear appropriate safety equipment, including protective eyewear, gloves, and a dust mask.

For heavily used surfaces, such as kitchen countertops, it’s important to remove any stubborn stains or mineral deposits using a specialized stone poultice. Test any cleaning products on a small, inconspicuous area first to ensure compatibility with your quartz surface.

Finally, ensure the surface temperature is between 50-80°F (10-27°C) for optimal product performance.

Polishing Process

Achieving a professional polish on quartz surfaces requires a systematic approach and the right techniques. Begin by thoroughly cleaning the surface to remove any debris or contaminants that could interfere with the polishing process. Start with a coarse diamond pad (typically 50-100 grit) for heavily worn surfaces, or begin with a medium grit (200-400) for lighter restoration work.

Work in small, manageable sections using overlapping circular motions while maintaining consistent pressure. Keep the surface wet during the entire process to prevent heat buildup and ensure optimal results. Gradually progress through finer grits (800, 1500, and 3000) until reaching the final polishing stage. Each progression should completely remove the scratches from the previous grit before moving forward.

For the final polish, use a high-quality polishing powder or compound specifically designed for quartz surfaces. Apply using a felt or foam pad attached to a variable-speed polisher set at 1000-1500 RPM. The surface should begin to develop a deep, mirror-like shine. For particularly challenging cases, consider consulting experts who specialize in professional restoration techniques.

After achieving the desired finish, thoroughly clean the surface and apply a protective sealer designed for quartz. This final step helps maintain the polish and protect against future wear. Allow the sealer to cure completely before resuming normal use of the surface.

Common Mistakes to Avoid

When polishing quartz surfaces, avoid using acidic cleaners or abrasive scouring pads, as these can etch or scratch the surface. A common mistake is applying excessive pressure during polishing, which can create uneven spots or damage the finish. Never use bleach-based products or vinegar solutions, as these can deteriorate the resin binding the quartz particles.

Temperature control is crucial – don’t use hot tools or extremely hot water during cleaning and polishing, as thermal shock can cause micro-cracks. Avoid leaving polishing compounds to dry on the surface, as they can become difficult to remove and may leave residue marks. Many homeowners make the error of using natural stone products intended for marble or granite on quartz, which can lead to unsatisfactory results.

Always test products in an inconspicuous area first, and don’t mix different polishing compounds during the same session. Skipping the manufacturer’s recommended dwell time or rushing through the process can result in subpar results. Remember that quartz doesn’t need sealing – attempting to apply sealers is unnecessary and can create a cloudy appearance.

Long-term Care and Maintenance

Daily Care Routine

Maintaining your polished quartz surfaces doesn’t have to be complicated. By following simple preventive maintenance strategies, you can preserve the lustrous finish of your quartz for years to come. Start each day by wiping surfaces with a soft microfiber cloth to remove dust and debris. For daily cleaning, use a pH-neutral stone cleaner or a mixture of warm water and mild dish soap. Avoid acidic cleaners, as these can damage the polish over time.

Always clean spills immediately to prevent staining, and use coasters under glasses and bottles to protect the surface. When wiping, use gentle circular motions rather than aggressive scrubbing. Keep cutting boards handy to prevent direct contact with sharp objects, and avoid placing hot items directly on the surface.

For optimal results, implement a two-step approach: dry dusting in the morning and a gentle wet cleaning in the evening. This routine takes just minutes but significantly extends the life of your quartz’s polish while maintaining its natural brilliance.

Professional Maintenance Schedule

For optimal maintenance of quartz surfaces, professional polishing services should be scheduled based on usage intensity and environmental factors. In residential settings with normal wear, professional polishing is recommended every 2-3 years. However, high-traffic commercial spaces may require professional attention annually or semi-annually.

Signs that indicate it’s time for professional maintenance include visible dulling, light scratches, or uneven surface appearance. Areas exposed to direct sunlight or harsh cleaning chemicals may need more frequent professional care, typically every 12-18 months.

For kitchen countertops, schedule professional polishing every 2 years if the surface receives regular daily care. Bathroom vanities and less frequently used surfaces can typically go 3-4 years between professional services. Commercial installations, especially in retail or hospitality settings, should be evaluated quarterly for polishing needs.

Keep a maintenance log to track professional services and monitor surface performance. This helps establish a customized timeline based on your specific usage patterns and environmental conditions, ensuring optimal care for your quartz surfaces.

Maintaining your quartz surfaces with the right polishing products and techniques is essential for preserving their beauty and durability. By selecting appropriate cleaning solutions, following proper application methods, and implementing regular maintenance routines, you can ensure your quartz surfaces retain their lustrous appearance for years to come. Remember to always test products on a small, inconspicuous area first, use non-abrasive materials, and follow manufacturer guidelines closely. Whether you’re a homeowner or industry professional, investing in quality quartz polishing products and understanding their correct usage will protect your investment and keep your surfaces looking pristine. With proper care and the right products, your quartz surfaces will continue to enhance the aesthetics and value of any space they grace.