Stone matrix technology revolutionizes natural stone authentication and traceability in today’s digital landscape. By combining blockchain’s immutable ledger with advanced material verification techniques, this groundbreaking system creates an unbreakable chain of custody for precious stone materials from quarry to final installation.

Industry leaders leverage stone matrix solutions to combat counterfeiting, ensure material authenticity, and maintain detailed provenance records throughout the supply chain. The technology’s multi-layered verification process incorporates geological fingerprinting, high-resolution imaging, and distributed ledger protocols to generate unique digital identifiers for each stone specimen.

For architects, designers, and stone industry professionals, stone matrix represents a quantum leap in material validation and project documentation. The system’s ability to instantly verify material origins, track processing steps, and confirm sustainability credentials addresses growing demands for transparency in luxury stone applications. This revolutionary approach not only safeguards material authenticity but also streamlines compliance reporting and enhances client confidence in stone selection decisions.

What is Stone Matrix Technology?

Digital Fingerprinting of Natural Stone

Modern technology has revolutionized how we identify and track natural stone through sophisticated digital stone verification systems. Each stone slab possesses unique characteristics – from its veining patterns and mineral compositions to microscopic surface textures – that create a distinct natural fingerprint. Using high-resolution imaging and advanced scanning technology, these distinctive features are captured and converted into detailed digital signatures.

The digitization process involves multiple layers of data collection, including spectral analysis, 3D surface mapping, and precise color documentation. These measurements are combined to create a comprehensive digital profile that’s as unique as a human fingerprint. This profile becomes an unalterable record in the stone matrix database, enabling instant verification of authenticity and origin.

The technology can detect subtle variations in pattern continuity, mineral distribution, and even microscopic fissures that distinguish genuine stone from imitations. This digital fingerprinting process has become an essential tool for maintaining material authenticity throughout the supply chain and ensuring the highest standards of quality control in the natural stone industry.

Matrix Data Points and Parameters

The stone matrix system captures essential data points that create a comprehensive digital identity for each stone. These parameters include unique physical characteristics such as dimensions, weight, color variations, and geological composition. The system also records origin information, including quarry location, extraction date, and batch numbers.

Critical quality indicators are documented, such as density measurements, absorption rates, and compression strength values. Processing details like cutting methods, surface finishing techniques, and treatments applied are logged to maintain complete material history.

The matrix additionally tracks chain-of-custody information, including transportation details, storage conditions, and handling procedures. Each transformation stage is time-stamped and verified, creating an immutable record of the stone’s journey from quarry to final installation.

For certification and compliance purposes, the system stores test results, quality certificates, and sustainability credentials. These data points combine to form a detailed digital passport that authenticates the stone’s identity, quality, and provenance throughout its lifecycle.

Blockchain Integration with Stone Matrix

Smart Contracts and Verification Process

Smart contracts form the backbone of the stone matrix verification process, operating as self-executing programs that automatically validate and record transactions on the blockchain. These digital agreements contain predefined rules and conditions that must be met before any stone-related transaction is confirmed and added to the immutable ledger.

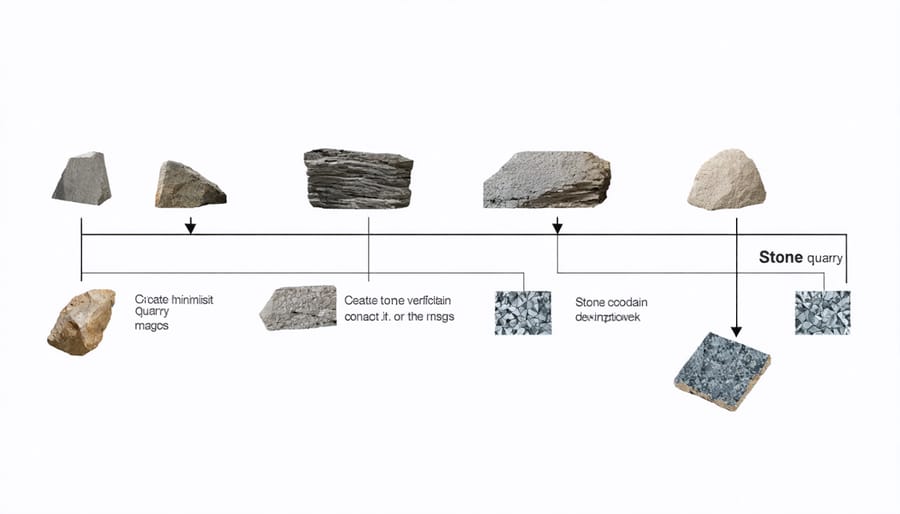

When natural stone materials enter the supply chain, they are assigned unique digital identifiers linked to their physical characteristics, origin, and quality certifications. The verification process begins with the initial quarry documentation and continues through processing, transportation, and final installation.

The smart contract automatically checks multiple data points, including:

– Quarry location coordinates

– Extraction date and batch numbers

– Material composition analysis

– Quality certification documents

– Transportation records

– Processing facility verification

Each verification step creates a new block of information that connects to previous records, forming an unbreakable chain of custody. This system ensures that every piece of stone can be traced back to its source, with all intermediary handling points documented and verified.

For added security, the verification process incorporates multi-signature requirements, meaning multiple authorized parties must confirm major transitions in the supply chain. This distributed consensus mechanism prevents unauthorized modifications and ensures the authenticity of stone materials throughout their journey from quarry to final installation.

Immutable Record Keeping

Stone matrix technology provides an unalterable record of every transaction and movement in the natural stone supply chain, creating a permanent historical document that cannot be modified or tampered with once recorded. This immutable record-keeping system offers unprecedented transparency and accountability in the stone industry.

Each block in the matrix contains crucial information about the stone’s journey, including quarry location, extraction date, processing details, and transportation records. These records are cryptographically secured and distributed across multiple nodes, making it virtually impossible to alter historical data without detection.

For architects, designers, and building owners, this permanent documentation provides valuable proof of material authenticity and origin. The system maintains detailed records of quality certifications, sustainability credentials, and handling procedures throughout the stone’s lifecycle. This comprehensive documentation can be particularly valuable for heritage projects, insurance purposes, and regulatory compliance.

The tamper-proof nature of stone matrix records also helps combat fraud and misrepresentation in the marketplace. Stakeholders can verify the complete history of their stone materials with confidence, knowing that the information hasn’t been manipulated. This level of documentation provides lasting value for future renovations, maintenance work, or property transfers, ensuring that critical material information remains accessible and trustworthy for generations to come.

Real-World Applications and Benefits

Supply Chain Transparency

Modern stone supply chain tracking utilizes blockchain technology and digital certification to ensure complete transparency from quarry to final installation. Each stone block receives a unique digital identifier at extraction, which follows it through processing, transportation, and installation phases. This creates an unalterable record of the material’s journey, authentication, and handling.

Quality control checkpoints throughout the supply chain verify and update the stone’s digital passport. Advanced scanning technology captures detailed imagery and geological data, while IoT sensors monitor environmental conditions during transport. This comprehensive tracking system allows stakeholders to verify material authenticity, assess quality parameters, and trace the stone’s complete journey.

For consumers and professionals, this transparency provides confidence in material sourcing and authenticity. Project managers can access real-time location updates, quality certificates, and processing documentation through secure digital platforms. The system also maintains detailed records of fabrication processes, treatments applied, and installation specifications.

This digital infrastructure has revolutionized traditional stone sourcing by eliminating documentation gaps and reducing the risk of material substitution. Architects and designers can now provide clients with complete material provenance, while installers benefit from detailed handling and maintenance specifications linked to each stone’s unique profile.

Quality Assurance and Verification

Quality assurance in stone matrix systems offers significant advantages across the supply chain, ensuring authenticity and value for all stakeholders. For suppliers, implementing robust quality control verification processes helps maintain product consistency and reduces liability risks. These systems enable real-time tracking of stone characteristics, origin certification, and processing standards compliance.

Contractors benefit from enhanced transparency in material sourcing and simplified documentation processes. The digital verification system provides immediate access to crucial information about stone properties, installation requirements, and maintenance specifications. This streamlined access reduces project delays and ensures appropriate material selection for specific applications.

End users gain confidence through verifiable authenticity and quality assurance measures. The matrix system provides detailed documentation of the stone’s journey from quarry to installation, including treatment processes and quality certifications. This transparency helps protect investments and ensures the selected materials meet specified requirements for their intended use.

The verification process also supports sustainable practices by enabling better resource management and reducing material waste through accurate tracking and quality control. This systematic approach to quality assurance creates a more efficient, reliable, and sustainable stone industry that benefits all participants in the supply chain.

Stone matrix technology has fundamentally transformed the natural stone industry, revolutionizing how we track, authenticate, and trade stone materials across global supply chains. By creating an immutable digital record of each stone’s journey from quarry to installation, this technology has significantly reduced fraud, enhanced transparency, and improved quality assurance throughout the industry.

The impact extends beyond mere traceability. Stone matrix systems have enabled more efficient inventory management, reduced waste, and created new opportunities for sustainable practices. Architects and designers now have unprecedented access to verified material histories, empowering them to make more informed decisions and meet increasingly stringent sustainability requirements.

Looking ahead, the integration of stone matrix technology with emerging innovations like artificial intelligence and IoT sensors promises even greater advances. These developments could enable real-time monitoring of stone quality, automated verification processes, and more sophisticated supply chain optimization. The technology is also expected to play a crucial role in meeting growing consumer demands for transparency and environmental responsibility.

As adoption continues to grow, stone matrix systems are likely to become the industry standard, fostering a more connected, efficient, and sustainable natural stone market. This evolution will benefit all stakeholders, from quarry operators to end consumers, while preserving the integrity and value of natural stone products for generations to come.