Secure your stone fabrication facility’s digital infrastructure by implementing multi-factor authentication across all smart equipment and control systems. Modern stone processing safety protocols now demand rigorous cybersecurity measures to protect both machinery and sensitive data.

Establish role-based access control (RBAC) to limit operator permissions based on job functions, preventing unauthorized equipment manipulation and protecting proprietary cutting specifications. Monitor and log all system access attempts, maintaining detailed audit trails that track who accessed which machines and when.

Integration of biometric verification systems with traditional password protection creates a robust defense against unauthorized access to CNC machinery and digital templating tools. Regular security audits, combined with automated threat detection systems, safeguard your facility’s network infrastructure while ensuring compliance with industry standards.

Train personnel in cybersecurity best practices, focusing on password management, social engineering awareness, and proper handling of digital assets. This human-centric approach, coupled with technological solutions, creates a comprehensive security framework that protects your stone fabrication operations from evolving cyber threats.

The Digital Evolution of Stone Equipment

Smart Features in Modern Stone Equipment

Modern stone fabrication equipment has evolved to incorporate sophisticated digital control systems that enhance precision and efficiency. CNC machines now feature IoT connectivity, allowing operators to monitor and control operations remotely through secure cloud platforms. These smart systems enable real-time tracking of machine performance, tool wear, and production metrics.

Remote monitoring capabilities provide fabricators with instant alerts about machine status, maintenance requirements, and potential issues, helping prevent costly downtime. Advanced automation features include tool path optimization, material waste reduction algorithms, and automated quality control systems that ensure consistent results across production runs.

However, these digital advancements also introduce potential cybersecurity vulnerabilities. Equipment manufacturers have responded by implementing encrypted communications, multi-factor authentication for remote access, and regular security updates. Facility managers must maintain strict access controls and network segmentation to protect these connected systems from unauthorized access.

Regular software updates and security patches are essential to protect against emerging threats, while proper staff training ensures safe operation of these sophisticated systems. The integration of smart features in stone equipment represents a significant advancement in the industry, but requires careful attention to cybersecurity protocols.

Potential Vulnerabilities

Smart stone equipment can be vulnerable to several security weaknesses that cybercriminals may exploit. Common vulnerabilities include default or weak passwords on CNC machines and digital templating devices, unsecured wireless networks in fabrication facilities, and outdated software on equipment control systems. Remote access features, while convenient for maintenance, can create potential entry points for unauthorized users if not properly secured. Unencrypted data transmission between design software and manufacturing equipment poses risks of data interception or manipulation. USB ports on machinery can be exploited to introduce malware, while insufficient employee training on cybersecurity protocols may lead to inadvertent security breaches. Regular security assessments and updates are essential to identify and address these vulnerabilities before they can be exploited.

Essential Access Control Measures

User Authentication Systems

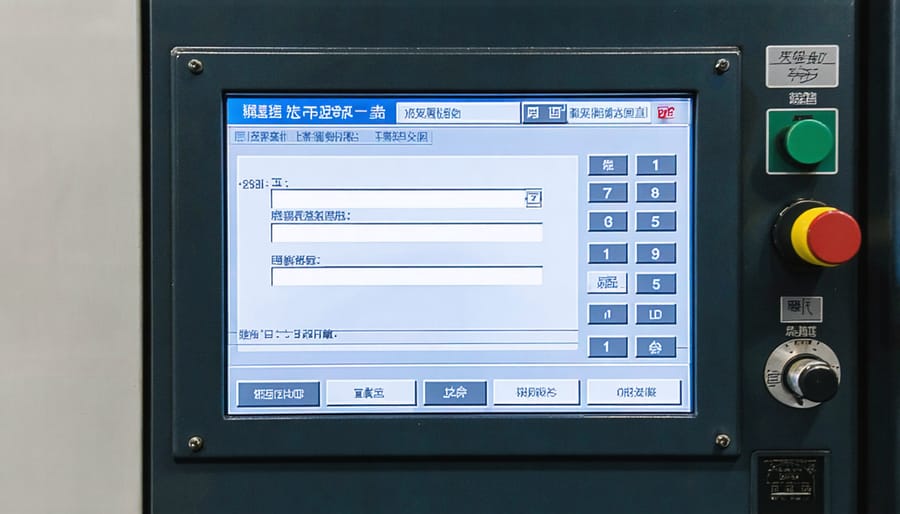

User authentication systems serve as the first line of defense in protecting access to stone fabrication equipment and facility management systems. These systems typically employ multiple verification methods to ensure only authorized personnel can access sensitive controls and data.

The most common authentication methods include password-based systems, which require unique combinations of characters, numbers, and symbols. While passwords remain widespread, they’re increasingly combined with additional security layers for enhanced protection.

Biometric authentication has gained prominence in industrial settings, using fingerprint scanners, facial recognition, or retinal scans to verify identity. These systems are particularly effective for stone fabrication facilities as they resist environmental factors like dust and moisture while providing quick, reliable access.

Multi-factor authentication (MFA) combines multiple verification methods, typically requiring something you know (password), something you have (security token or mobile device), and something you are (biometric data). This layered approach significantly reduces the risk of unauthorized access.

Smart card systems and RFID badges offer convenient solutions for facility access control, allowing managers to easily grant, modify, or revoke access permissions. These systems also maintain detailed access logs, essential for security auditing and compliance requirements.

When implementing authentication systems, it’s crucial to balance security requirements with operational efficiency, ensuring protection doesn’t impede productivity in stone fabrication workflows.

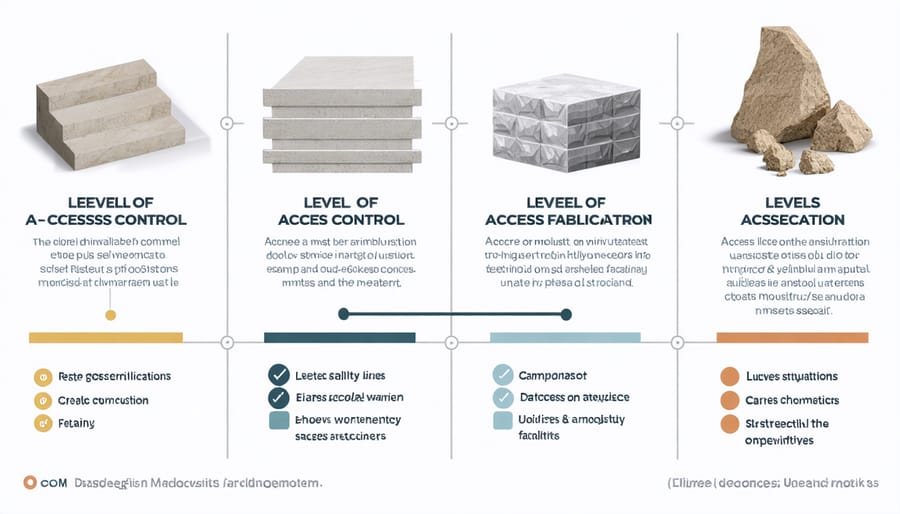

Role-Based Access Control

Role-Based Access Control (RBAC) is a fundamental approach to managing user permissions in stone fabrication facilities and smart manufacturing environments. This system assigns access rights based on specific roles within the organization, ensuring that employees can only access the resources necessary for their job functions.

In a typical stone fabrication facility, RBAC might include roles such as machine operators, quality control inspectors, maintenance technicians, and facility managers. Each role is assigned specific permissions aligned with their responsibilities. For example, machine operators might have access to equipment controls and basic diagnostic tools, while maintenance technicians receive additional permissions for advanced system configurations and troubleshooting features.

Implementation begins with identifying core roles and their required access levels. Facility managers should document these roles clearly, including which systems, data, and equipment each role needs to access. Regular audits of role assignments help ensure that permissions remain appropriate as job responsibilities evolve.

Best practices for RBAC implementation include:

– Maintaining detailed documentation of role definitions

– Following the principle of least privilege

– Implementing regular permission reviews

– Creating standardized procedures for role changes

– Establishing emergency access protocols

When setting up RBAC, consider both physical and digital access requirements. This might include machine control panels, inventory systems, quality control databases, and maintenance scheduling software. Regular training ensures all users understand their access limitations and security responsibilities.

Remote Access Security

Remote access has become essential in modern stone fabrication facilities, allowing technicians and managers to monitor and control equipment from anywhere. However, this convenience comes with significant security risks that must be addressed through comprehensive protective measures.

Start by implementing strong authentication protocols, including multi-factor authentication (MFA) for all remote connections. This ensures that even if passwords are compromised, unauthorized users cannot gain access to your systems. Virtual Private Networks (VPNs) should be mandatory for all remote connections, creating an encrypted tunnel that protects data transmission between remote users and your facility’s network.

Regular monitoring of remote access logs helps identify suspicious activities or unauthorized access attempts. Set up automated alerts for unusual login patterns or after-hours access. Implement strict session timeouts and automatic disconnection policies to prevent unauthorized access through abandoned connections.

For equipment vendors requiring remote access for maintenance, establish dedicated secure channels with limited permissions. Create temporary access credentials that expire after maintenance is complete, and ensure all vendor connections are logged and monitored.

Consider implementing Network Access Control (NAC) solutions that verify the security status of devices before allowing remote connections. This helps prevent compromised devices from accessing your network. Regular security audits of remote access systems, combined with employee training on secure remote work practices, create a robust defense against potential cyber threats.

Implementation Strategies

Security Policy Development

Developing comprehensive security policies is a critical foundation for protecting your stone fabrication equipment and data assets. These policies should align with established shop management security practices while addressing the unique challenges of digital access control.

Start by conducting a thorough risk assessment of your facility’s equipment and systems. Identify critical assets, potential vulnerabilities, and the specific threats they face. This evaluation will help determine appropriate security levels and access requirements for different areas and equipment types.

Your security policy should clearly define:

– User roles and responsibilities

– Access level classifications

– Authentication requirements

– Password policies and management

– Equipment usage protocols

– Incident reporting procedures

– Emergency access protocols

– Regular security audit schedules

Document these policies in clear, accessible language and ensure all staff members receive proper training. Include specific procedures for granting, modifying, and revoking access privileges as personnel changes occur. Consider implementing a formal review process where employees acknowledge their understanding of security policies.

Regular policy reviews and updates are essential to address emerging threats and technological changes. Schedule quarterly assessments to evaluate policy effectiveness and make necessary adjustments. This proactive approach helps maintain robust security while supporting operational efficiency.

Remember that security policies must balance protection with practicality. Overly restrictive measures can hinder productivity, while insufficient controls leave your operation vulnerable. The goal is to create guidelines that safeguard assets while enabling smooth workflow processes.

Staff Training and Compliance

Effective staff training is crucial for maintaining robust access control security in stone fabrication facilities. Regular training sessions should cover basic cybersecurity principles, proper authentication procedures, and the handling of sensitive data. All employees must understand their role in maintaining security protocols and be familiar with industry safety standards.

Training programs should include hands-on practice with access control systems, emergency response procedures, and regular updates on new security threats. Staff members need to understand the importance of strong password policies, multi-factor authentication, and the proper handling of access credentials. Regular compliance audits ensure that security protocols are being followed consistently.

Documentation of all training sessions, including attendance records and assessment results, should be maintained. This creates an audit trail and helps identify areas where additional training may be needed. New employees should undergo comprehensive security orientation before being granted system access, while existing staff should participate in refresher courses at least annually.

Security awareness should be reinforced through regular communications, including updates on potential threats, reminders of best practices, and recognition of employees who demonstrate excellent security consciousness. Creating a culture of security awareness helps ensure that access control measures remain effective and that all staff members take their security responsibilities seriously.

Management should also establish clear consequences for security protocol violations and ensure consistent enforcement. Regular evaluation of training effectiveness helps identify gaps in knowledge and areas where protocols may need updating to address emerging threats.

Monitoring and Maintenance

Regular Security Audits

Regular security audits are critical components of maintaining robust access control systems in stone fabrication facilities. These assessments, which should be conducted quarterly, help identify potential vulnerabilities before they can be exploited. During these audits, teams should review user access logs, verify authentication protocols, and ensure all essential safety measures are functioning correctly.

A comprehensive audit checklist should include:

– Verification of all user credentials and access levels

– Testing of physical security components

– Review of network security protocols

– Assessment of backup systems

– Evaluation of emergency access procedures

– Documentation of any security incidents

It’s recommended to maintain detailed records of each audit, including findings, implemented solutions, and follow-up actions. This documentation creates a valuable historical record that can help identify patterns and prevent future security breaches. Consider engaging third-party security professionals annually to provide an unbiased assessment and ensure compliance with industry standards. Regular training sessions should follow each audit to keep staff updated on security protocols and best practices.

Incident Response Planning

Even the most robust access control systems can face security breaches, making incident response planning crucial for stone fabrication facilities. A well-structured incident response plan helps organizations react swiftly and effectively when security incidents occur, minimizing potential damage and downtime.

Start by creating a detailed documentation of all access control systems, including smart stone equipment and security protocols. Establish a clear chain of command and designate specific roles for team members during security incidents. This should include identifying who has authority to make critical decisions and who will handle communications with stakeholders.

Develop step-by-step procedures for different types of security breaches, from unauthorized physical access to cyber attacks on networked stone fabrication equipment. Include specific actions for containment, evidence collection, and system recovery. Regular training sessions and simulated breach scenarios help ensure team members understand their responsibilities and can act decisively during actual incidents.

After any security incident, conduct thorough post-incident analysis to identify vulnerabilities and improve response procedures. This continuous improvement process helps strengthen your overall security posture and prevents similar incidents in the future.

Access control cybersecurity is not a one-time implementation but rather an ongoing commitment to protecting your facility’s digital assets. As we’ve explored throughout this article, effective security measures require a multi-layered approach combining physical access controls, digital authentication systems, and robust network security protocols.

Regular system audits, employee training, and staying current with emerging threats are crucial for maintaining a strong security posture. Remember that cybercriminals constantly evolve their tactics, making it essential to regularly update security protocols and access policies. This includes reviewing user permissions, updating authentication methods, and patching security vulnerabilities as they’re discovered.

For stone fabrication facilities utilizing smart equipment, the stakes are particularly high. A security breach could not only compromise sensitive data but also disrupt production operations and damage expensive machinery. By maintaining vigilant security practices and fostering a security-conscious culture among staff, facilities can significantly reduce their risk exposure.

Success in access control security comes from striking the right balance between protection and usability while remaining adaptable to new security challenges and technological advances.