Stone restoration stands at the intersection of architectural preservation and environmental stewardship, demanding a delicate balance between honoring historical integrity and embracing sustainable practices. Through smart stone restoration practices, craftsmen now combine centuries-old techniques with cutting-edge conservation methods to breathe new life into weathered monuments, facades, and architectural elements.

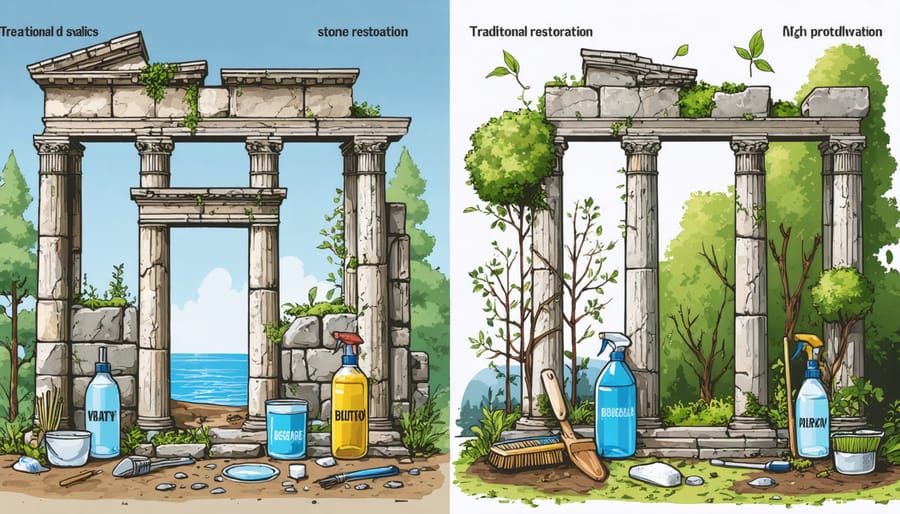

Modern stone restoration transcends simple repairs, encompassing comprehensive preservation strategies that consider both immediate structural needs and long-term environmental impact. From the careful selection of eco-friendly cleaning agents to the implementation of non-invasive restoration techniques, every step requires precise execution and deep material understanding.

The stakes are particularly high when working with historic structures, where each intervention must preserve not only the physical stone but also its cultural significance. Advanced diagnostic tools, coupled with traditional craftsmanship, enable restorers to develop targeted solutions that protect our architectural heritage while minimizing environmental footprint. This approach ensures that restored stonework maintains its authenticity while meeting contemporary sustainability standards.

The Environmental Impact of Traditional Stone Restoration

Chemical Usage and Environmental Concerns

Traditional stone restoration often relies on chemical cleaners and treatments that can pose significant environmental concerns. While these products effectively address weathering and erosion effects, many contain harsh acids, alkaline compounds, and volatile organic compounds (VOCs) that can harm ecosystems and groundwater systems.

Common cleaning agents like hydrofluoric acid and sodium hydroxide, though effective at removing stubborn stains and deposits, require careful handling and disposal. These chemicals can alter soil pH levels, damage surrounding vegetation, and potentially contaminate water sources. Additionally, some sealants and consolidants used in stone preservation contain petroleum-based compounds that release harmful emissions during application and curing.

The industry is increasingly adopting eco-friendly alternatives, including biodegradable cleaners, pH-neutral solutions, and water-based sealants. These sustainable options minimize environmental impact while maintaining restoration effectiveness. Modern practitioners now emphasize proper dilution ratios, controlled application methods, and responsible waste management to reduce ecological footprint without compromising results.

Resource Consumption in Traditional Methods

Traditional stone restoration methods, while effective, often consume substantial resources that impact both the environment and operational costs. Water usage is particularly significant, with conventional cleaning processes requiring up to 5-7 gallons per square foot of stone surface. High-pressure washing, a common technique, can use even more water while potentially causing surface damage to delicate stone materials.

Energy consumption in traditional restoration is equally concerning. Power tools, heating equipment for chemical treatments, and industrial cleaning machinery typically operate for extended periods, drawing considerable electricity. Climate-controlled environments, often necessary for certain restoration processes, further increase energy demands. Additionally, the transportation and operation of heavy equipment contribute to the overall energy footprint.

Chemical cleaning agents used in conventional methods not only require resources for their production but also necessitate additional water for rinsing and neutralization steps. The cumulative effect of these resource-intensive practices has led many restoration professionals to seek more sustainable alternatives that maintain restoration quality while reducing environmental impact.

Sustainable Restoration Techniques

Green Cleaning Solutions

In recent years, the stone restoration industry has embraced eco-friendly cleaning solutions that deliver excellent results while protecting both the environment and the stone’s integrity. Natural cleaning alternatives like citrus-based degreasers, enzymatic cleaners, and plant-based surfactants effectively remove dirt and stains without the harsh chemicals found in traditional products.

Baking soda paste serves as an excellent gentle abrasive for tackling stubborn stains, while white vinegar diluted with water can effectively clean most stone surfaces when used appropriately. However, it’s crucial to note that acidic solutions should never be used on calcium-based stones like marble or limestone, as they can cause etching.

For regular maintenance, a mixture of pure castile soap and warm water provides a safe and effective cleaning solution. Plant-based hydrogen peroxide alternatives offer powerful stain-lifting properties without environmental concerns. These green solutions not only protect the stone but also improve indoor air quality by eliminating toxic fumes and residues.

Professional stone restorers now incorporate biodegradable poultices and enzyme-based cleaners that break down organic stains naturally. These solutions are particularly effective on outdoor stone features, as they pose no risk to surrounding vegetation or groundwater. When combined with microfiber cloths and reusable cleaning tools, these eco-friendly methods create a comprehensive sustainable approach to stone care and restoration.

Water Conservation Methods

Water conservation in stone restoration has become increasingly critical as sustainability concerns grow. Modern restoration projects employ several effective techniques to minimize water usage while maintaining quality results. Closed-loop water recycling systems capture and filter water used during cleaning processes, allowing it to be reused multiple times before disposal. These systems can reduce water consumption by up to 80% compared to traditional methods.

Low-flow pressure washing equipment, fitted with specialized nozzles, delivers precise water streams that maximize cleaning efficiency while using significantly less water. Dry cleaning methods, such as micro-abrasive blasting and latex cleaning compounds, can often achieve excellent results without water usage for suitable stone types.

Moisture meters help technicians accurately assess stone conditions, preventing unnecessary wet cleaning procedures. Additionally, timed automatic shut-off systems prevent water waste during cleaning operations. Collecting rainwater for non-critical cleaning tasks and scheduling work during cooler hours to minimize evaporation further contribute to water conservation efforts.

These methods not only support environmental sustainability but also help reduce project costs and comply with increasingly stringent water usage regulations in many jurisdictions.

Energy-Efficient Equipment

Today’s modern conservation technology has revolutionized stone restoration with energy-efficient equipment that significantly reduces environmental impact while maintaining superior results. Variable-speed diamond grinding machines now feature smart power management systems that optimize energy consumption based on the stone’s hardness and required finish level.

LED-powered UV curing systems have replaced traditional heat-intensive methods, reducing electricity usage by up to 75% while accelerating the curing process for sealants and protective coatings. Advanced vacuum systems with HEPA filtration operate on high-efficiency motors, capturing dust and debris while consuming minimal power.

Innovative water recycling systems integrated into wet-processing equipment reduce both water consumption and the energy required for heating and processing. Digital monitoring devices ensure optimal tool performance, preventing unnecessary power usage from worn or inefficient equipment. These improvements not only lower operational costs but also align with sustainable preservation practices, making stone restoration more environmentally responsible without compromising quality.

Material Conservation and Recycling

Stone Salvage and Reuse

In line with modern preservation ethics, salvaging and reusing original stone materials is a crucial aspect of responsible restoration work. This approach not only maintains historical authenticity but also reduces environmental impact and preserves the unique patina that develops over time.

The salvage process begins with careful documentation and labeling of existing stones before removal. Each piece is photographed, measured, and mapped to ensure accurate repositioning. Damaged stones are evaluated for potential repair rather than immediate replacement, using techniques such as stone dutchman repairs, where only the damaged portion is replaced with matching material.

Salvaged stones can be repurposed within the same project or carefully stored for future use. When stones must be replaced, the original materials are often crushed and used as aggregate in compatible mortars or as sub-base material, ensuring nothing goes to waste. This approach is particularly valuable when working with rare or historically significant stone types that are no longer quarried.

For successful stone salvage, proper cleaning and storage conditions are essential. Stones should be kept in a dry, protected environment and properly supported to prevent further damage. Regular assessment of stored materials helps maintain their integrity until they can be reintegrated into restoration projects.

Waste Management Practices

Responsible waste management is crucial in stone restoration work to minimize environmental impact and comply with regulations. Stone restoration typically generates various types of waste, including stone dust, chemical residues, packaging materials, and removed sealants or coatings.

The first step in proper waste management is categorization. Materials should be sorted into recyclable stone waste, hazardous chemicals, and general construction debris. Stone dust and small fragments can often be repurposed as aggregate in new construction projects or landscaping applications. Larger stone pieces may be suitable for other restoration projects or decorative uses.

Chemical waste requires special handling due to its potentially harmful environmental effects. Used cleaning solutions, strippers, and sealants must be collected in appropriate containers and disposed of through licensed hazardous waste facilities. Never dispose of these materials in regular trash or pour them down drains.

Many restoration professionals now implement closed-loop water recycling systems during wet processing to minimize water waste and prevent contaminated runoff. These systems filter and reuse water, significantly reducing environmental impact and operating costs.

Packaging materials like plastic containers, cardboard boxes, and protective wrapping should be separated for recycling whenever possible. Some suppliers offer take-back programs for empty chemical containers and packaging materials.

Documentation of waste disposal practices is essential for compliance and environmental certification purposes. Maintain detailed records of waste volumes, disposal methods, and recycling initiatives to demonstrate responsible management practices.

Case Studies in Sustainable Stone Restoration

The restoration of Milan’s Duomo Cathedral stands as a remarkable example of sustainable stone conservation. In 2019, conservators employed innovative bio-based cleaning solutions and locally sourced materials to restore the cathedral’s intricate marble facade. This project reduced chemical usage by 60% compared to traditional methods while achieving superior cleaning results.

In Portland, Oregon, the Pioneer Courthouse restoration project showcases how modern sustainable practices can preserve historic sandstone. Restoration specialists utilized rainwater harvesting systems for cleaning processes and implemented solar-powered ventilation to control moisture levels. The project’s waste reduction program successfully recycled 85% of removed stone materials for use in other restoration works.

The Sydney Opera House’s ongoing maintenance program demonstrates excellence in sustainable stone care. Conservators developed a revolutionary monitoring system using IoT sensors to detect early signs of deterioration, allowing for preventive rather than reactive maintenance. This approach has reduced the need for intensive restoration by 40% while extending the lifespan of the building’s iconic shell tiles.

In Edinburgh, Scotland, the Holyrood Palace restoration team pioneered the use of bacterial cleaning techniques to remove centuries of pollution damage from limestone surfaces. This biological approach eliminated the need for harsh chemicals and reduced water consumption by 75% compared to conventional methods. The success of this project has influenced stone restoration practices throughout the United Kingdom.

The Getty Center in Los Angeles implemented a comprehensive stone preservation strategy that combines traditional craftsmanship with sustainable technologies. Their integrated approach includes:

– Using photocatalytic coatings that self-clean when exposed to sunlight

– Implementing precision water management systems that reduce cleaning water usage by 80%

– Developing site-specific biological treatments for different stone types

– Creating a digital monitoring system for early detection of deterioration

These case studies demonstrate that sustainable stone restoration not only benefits the environment but often provides superior long-term results and cost savings. The success of these projects has helped establish new industry standards for environmentally responsible stone conservation practices.

As we look to the future of stone restoration, the integration of sustainable practices with traditional craftsmanship stands as a cornerstone of preservation efforts. The industry has made significant strides in developing eco-friendly cleaning solutions, utilizing water recycling systems, and implementing energy-efficient equipment, demonstrating that environmental responsibility and historic preservation can work hand in hand.

Key takeaways from modern stone restoration approaches include the importance of preventive maintenance, the value of material-specific treatments, and the growing role of technology in assessment and documentation. These practices not only extend the life of stone features but also reduce the need for intensive restoration interventions, ultimately lowering environmental impact.

The outlook for sustainable stone restoration is promising, with ongoing research into bio-based consolidants, non-toxic cleaning agents, and advanced diagnostic tools. Industry professionals are increasingly adopting these innovations while maintaining respect for traditional techniques that have proven effective over centuries.

Looking ahead, we can expect to see greater emphasis on training programs that combine historical knowledge with sustainable practices, ensuring that future generations of stone restoration specialists are equipped to meet both conservation and environmental challenges. The integration of digital documentation methods and preventive maintenance strategies will likely become standard practice, helping to preserve our architectural heritage while minimizing ecological footprint.

Success in stone restoration will continue to rely on finding the right balance between preserving historical authenticity and embracing sustainable solutions that protect both our cultural legacy and the environment.