Revolutionizing memorial craftsmanship, modern laser imaging technology has transformed headstone engraving from a manual craft into a precise, digital art form. These sophisticated machines now deliver unmatched detail, consistency, and efficiency in memorial production, enabling artisans to create intricate designs and photorealistic portraits with exceptional accuracy.

For memorial businesses and stone craftsmen, laser engraving systems represent a critical investment that bridges traditional craftsmanship with cutting-edge precision. Whether replicating classical religious symbols or producing contemporary custom designs, these machines offer versatility that meets evolving customer demands while maintaining the solemnity and permanence expected in memorial work.

The technology’s ability to handle various stone types, from granite to marble, while providing consistent results across multiple projects has made it indispensable in modern monument production. As demand grows for personalized memorials featuring detailed photographs, custom artwork, and precise lettering, laser engraving machines have become essential tools for competitive memorial businesses seeking to deliver superior quality and craftsmanship in their work.

How Modern Laser Engraving Machines Work

Core Components and Technology

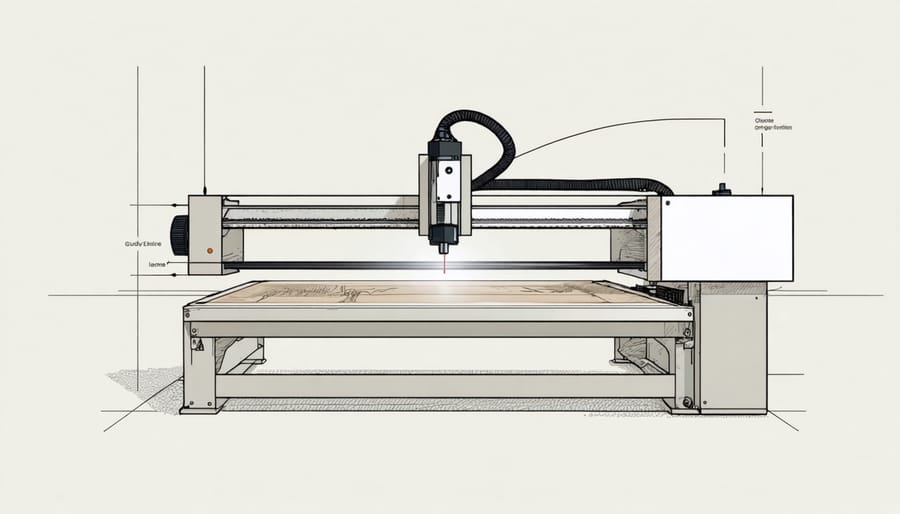

Modern headstone laser engraving machines rely on three primary components that work in harmony to create precise and lasting memorials. The heart of these systems is typically a CO2 laser tube, ranging from 30 to 100 watts, which produces an intense beam capable of marking and engraving various stone surfaces. These lasers operate at a wavelength of 10.6 micrometers, ideal for working with granite and marble.

The motion control system consists of high-precision stepper motors and linear guides that move the laser head across X and Y axes with accuracy down to 0.01mm. This precision ensures every detail of the design is faithfully reproduced on the stone surface.

The control interface usually features advanced software that converts digital artwork into machine instructions. Modern systems support common file formats like AI, JPG, and BMP, while offering specialized tools for text manipulation and image processing. Most machines include auto-focus mechanisms that maintain the optimal distance between the laser head and stone surface.

The power supply unit delivers stable, regulated power to both the laser source and control systems, often incorporating safety features like emergency shutoffs and thermal protection circuits.

Software and Design Interface

Modern headstone laser engraving machines integrate seamlessly with sophisticated Computer-Aided Design (CAD) systems and specialized monument design software. These digital tools allow artists and craftspeople to create intricate designs with precision and flexibility. Popular software packages like Monument Designer Pro and Laser Works offer user-friendly interfaces that support both 2D and 3D design capabilities.

The workflow typically begins with importing or creating artwork in vector format, which ensures clean lines and scalability. Advanced AI-powered design software now enables realistic previews of how engravings will appear on different stone types and textures. These programs also include extensive libraries of common memorial symbols, fonts, and decorative elements.

Most software solutions feature built-in parameter controls for laser power, speed, and depth settings, ensuring consistent results across projects. They also offer tools for estimating engraving time and material costs, helping operators optimize production efficiency. Quality control features like virtual proofing allow customers to review and approve designs before the actual engraving begins.

Advantages of Laser Engraving for Memorials

Precision and Detail Quality

Laser engraving machines have revolutionized modern stone carving techniques, particularly in achieving unprecedented levels of precision and detail quality in headstone craftsmanship. These machines can consistently produce intricate designs with line widths as fine as 0.1mm, allowing for remarkably detailed portraits, elaborate text styles, and complex decorative elements that would be challenging to achieve through traditional methods.

The precision of laser engraving is attributed to its computer-controlled operation, which maintains absolute accuracy across the entire working surface. This technology ensures that every curve, line, and point is executed exactly as designed, eliminating the variations that can occur with hand engraving. The laser beam’s focused intensity creates clean, sharp edges and consistent depth throughout the engraving process.

Additionally, laser engraving machines excel at reproducing photographic images on stone surfaces. Through precise control of laser power and speed, these systems can create various shading effects and gradients, resulting in lifelike portraits with remarkable depth and dimension. The technology can accurately reproduce up to 256 different gray levels, enabling subtle variations in tone that bring memorial photographs to life.

The consistency of laser engraving also ensures that multiple identical designs can be reproduced with exact precision, making it ideal for creating matching family monuments or duplicate elements across different headstones. This level of detail and reproducibility has set new standards in memorial craftsmanship, offering families more sophisticated options for commemorating their loved ones.

Time and Cost Efficiency

Laser engraving machines offer significant advantages in both time and cost efficiency compared to traditional hand-carving methods. A skilled operator can complete a standard headstone engraving in 2-3 hours, while traditional methods might require 1-2 days of labor. This dramatic reduction in production time allows memorial businesses to handle more orders and improve customer satisfaction through faster turnaround times.

From a cost perspective, while the initial investment in laser equipment ranges from $30,000 to $100,000, the long-term savings are substantial. Operating costs primarily consist of electricity usage (approximately $1-2 per hour) and minimal maintenance expenses. Traditional hand-carving requires skilled artisans commanding higher wages, plus the cost of specialized tools and their replacement.

The precision of laser engraving also reduces material waste and error rates. With digital design capabilities, corrections can be made before engraving begins, eliminating costly mistakes that might require stone replacement. Most machines can operate continuously with minimal supervision, allowing staff to handle other tasks simultaneously.

For businesses handling multiple orders, the automated workflow enables batch processing, further increasing efficiency. A single operator can manage multiple machines, effectively multiplying production capacity without proportionally increasing labor costs. These efficiencies typically result in a return on investment within 12-24 months for most memorial businesses.

Choosing the Right Laser Engraving Machine

Power and Speed Requirements

Selecting the right power and speed settings for your laser engraving machine is crucial for achieving optimal results on headstones. Different stone types require varying levels of power to create crisp, lasting engravings while avoiding damage to the material.

For granite headstones, which are among the most common, a minimum of 30W laser power is recommended, though professional-grade machines typically operate in the 50-100W range. Higher power settings allow for deeper engravings and faster completion times. Dark granite typically requires more power than lighter varieties to achieve visible contrast.

Marble headstones generally require less power, usually between 20-40W, due to their softer composition. However, speed settings must be carefully controlled to prevent scorching or unwanted depth variations. For both marble and granite, slower speeds (typically 100-300mm/second) produce deeper, more defined engravings, while faster speeds create lighter marks suitable for subtle details.

Modern laser engravers feature adjustable power settings, allowing operators to fine-tune output based on:

– Stone density and hardness

– Desired engraving depth

– Color and reflectivity of the material

– Complexity of the design

– Required production speed

For professional headstone engraving services, machines rated at 80W or higher are recommended to handle diverse stone types and maintain efficient production schedules. These higher-powered systems offer greater versatility and can accommodate both delicate portrait work and deep letter cutting without compromising quality or speed.

Remember to always test power and speed settings on sample pieces before working on actual headstones to ensure optimal results and prevent material damage.

Size and Workspace Considerations

When setting up a laser engraving machine for headstone work, proper space planning is crucial for both operational efficiency and safety. Most commercial-grade headstone laser engravers require a minimum floor space of 8 feet by 6 feet, with additional clearance needed for maintenance access and material handling.

The working area typically consists of three zones: the laser engraving machine itself, a staging area for stone preparation, and storage space for completed work. A standard workspace should measure approximately 15 feet by 12 feet to accommodate all these elements comfortably.

Ceiling height is another critical consideration, as many machines require at least 8 feet of vertical clearance. This allows for the proper ventilation system installation and ensures adequate space for loading and unloading headstones using lifting equipment.

The machine’s footprint varies depending on the model and maximum workpiece size it can handle. Typical dimensions range from:

– Small units: 4′ x 3′ (suitable for smaller memorials)

– Medium units: 6′ x 4′ (most common for standard headstones)

– Large units: 8′ x 5′ or larger (for oversized monuments)

Remember to account for peripheral equipment such as water chillers, air compressors, and ventilation systems. These components often require an additional 20-30 square feet of space. Environmental controls are essential, so the workspace should be climate-controlled with temperatures maintained between 60-75°F and humidity levels below 70%.

For optimal workflow, consider creating designated paths for material movement and ensuring proper electrical connections are available throughout the workspace. A well-planned layout not only improves efficiency but also helps maintain workplace safety standards.

Maintenance and Care

Regular Maintenance Schedule

Regular maintenance of your laser engraving machine is crucial for ensuring optimal performance and longevity. Implement a daily cleaning routine that includes wiping down the laser lens and mirrors with specialized optical cleaning solutions. Check and clean the ventilation system to prevent dust accumulation, which can affect the laser’s efficiency and stone surface protection.

Weekly maintenance should include inspecting all mechanical components, lubricating moving parts, and checking the alignment of mirrors and beam path. Monthly tasks involve deeper cleaning of the entire system, including the exhaust ducts and filters. Replace filters according to manufacturer specifications, typically every 3-6 months depending on usage.

Quarterly maintenance requires professional calibration of the laser system, thorough inspection of electrical connections, and testing of safety systems. Annual maintenance should include comprehensive system diagnostics, replacement of worn components, and professional servicing of the laser tube.

Keep detailed maintenance logs documenting all procedures, dates, and any issues encountered. This helps track machine performance and anticipate potential problems before they affect production. Schedule maintenance during off-peak hours to minimize disruption to operations, and always maintain a stock of essential replacement parts and cleaning supplies.

Troubleshooting Common Issues

When operating a headstone laser engraving machine, several common issues may arise. Here’s how to address them effectively:

Poor Image Quality: If engravings appear blurry or inconsistent, first check the focus settings and ensure the laser head is at the correct height. Clean the lens thoroughly and verify that your image file meets the required resolution specifications.

Uneven Engraving Depth: This often results from an unleveled stone surface or inconsistent laser power. Use a digital level to ensure the headstone is perfectly flat, and regularly calibrate your laser power settings. Consider creating a test grid on scrap material before working on the actual headstone.

Software Communication Errors: If your machine isn’t responding to commands, check all USB or network connections. Restart both the computer and the engraving machine, and ensure your software drivers are up to date.

Smoke Marks: Excess debris during engraving can cause unwanted marks. Keep the ventilation system clean and functioning properly. Regular maintenance of air filters and exhaust systems prevents this issue.

Material Cracking: To prevent stone damage, never exceed recommended power settings for your specific material. Always start with conservative settings and gradually adjust as needed.

Preventive measures include:

– Daily cleaning of optical components

– Regular software updates

– Maintaining consistent room temperature

– Keeping detailed maintenance logs

– Performing weekly calibration checks

– Storing stones in a climate-controlled environment

These steps will help ensure reliable operation and high-quality results.

Laser engraving technology has revolutionized the headstone industry, offering unprecedented precision, versatility, and efficiency in memorial craftsmanship. As we’ve explored throughout this article, these machines combine advanced optics, powerful lasers, and sophisticated software to create detailed, lasting tributes on various stone surfaces.

The advantages of laser engraving machines are clear: consistent quality, faster production times, and the ability to create intricate designs that would be challenging or impossible with traditional methods. Business owners and memorial craftspeople have found these machines to be valuable investments that expand their service offerings while maintaining high standards of craftsmanship.

Looking ahead, the future of headstone laser engraving appears promising. Technological advances continue to improve machine capabilities, with developments in laser precision, software integration, and automation leading the way. We’re seeing trends toward more personalized memorials, with families requesting increasingly detailed portraits, custom artwork, and QR codes linking to digital memories.

As the technology becomes more accessible and user-friendly, we can expect to see wider adoption across the memorial industry. Manufacturers are focusing on developing more compact, efficient machines with enhanced features like improved dust collection systems and simplified maintenance procedures. These improvements will make laser engraving even more attractive to businesses of all sizes.

For those considering entering the memorial industry or upgrading their existing equipment, laser engraving machines represent a forward-thinking investment in both technology and craftsmanship.