Factor technology revolutionizes modern stone quarrying by merging advanced materials science with precision engineering. This groundbreaking approach transforms traditional extraction methods through controlled micro-fracturing, delivering superior efficiency while preserving stone integrity.

In quarries worldwide, factor technology has redefined productivity benchmarks by reducing waste by up to 40% compared to conventional methods. The system employs specialized expansive compounds that work in harmony with the stone’s natural grain patterns, enabling precise blocks to be extracted with minimal environmental impact.

At its core, this innovation represents a significant leap forward in sustainable quarrying practices. By eliminating the need for explosive charges and reducing mechanical stress on stone deposits, factor technology ensures higher-quality yields while maintaining the structural integrity of surrounding rock formations. For industry professionals and project managers, this translates to more predictable outcomes, reduced operational costs, and enhanced worker safety.

The technology’s adoption marks a critical shift in how we approach natural stone extraction, balancing commercial efficiency with environmental responsibility. As construction demands grow globally, factor technology stands as a testament to how innovative solutions can address both productivity and sustainability challenges in modern quarrying operations.

The Evolution of Stone Extraction Methods

Traditional Quarrying Challenges

Before the advent of modern technology, quarrying relied heavily on traditional stone craftsmanship methods that posed significant challenges. Workers used basic tools like wedges, hammers, and chisels to extract stone blocks, a process that was both labor-intensive and time-consuming. These manual techniques often resulted in substantial material waste, with up to 60% of extracted stone being discarded due to irregular breaks and imperfections.

The unpredictable nature of traditional methods also made it difficult to maintain consistent quality and block sizes. Weather conditions significantly impacted work schedules, and safety concerns were paramount due to the physical nature of the work. Production capacity was limited by human endurance and daylight hours, making it challenging to meet growing market demands.

Additionally, these conventional approaches often resulted in environmental concerns, including excessive noise, dust generation, and substantial site disruption. The inability to precisely control the extraction process meant that quarry sites frequently suffered from poor resource utilization and increased environmental impact.

The Factor Technology Revolution

Factor technology represents a groundbreaking advancement in natural stone processing, fundamentally transforming how we extract, cut, and finish stone materials. This innovative approach combines precision engineering with digital monitoring systems to optimize stone production while minimizing waste and environmental impact. By integrating advanced sensors, automated cutting mechanisms, and intelligent material handling, factor technology delivers consistently superior results compared to traditional methods.

The revolution lies in its ability to analyze and adjust to various stone characteristics in real-time, ensuring optimal processing parameters for each unique piece. This smart technology considers factors such as material density, grain direction, and natural faults to determine the most efficient cutting paths and finishing techniques. The result is a significant improvement in productivity, with some quarries reporting up to 40% increased yield and 30% reduced processing time.

What makes factor technology truly revolutionary is its accessibility and scalability. From small architectural studios to large-scale quarrying operations, this technology can be adapted to meet specific production needs while maintaining exceptional quality standards. This democratization of advanced stone processing has opened new possibilities for designers and manufacturers alike.

How Factor Technology Works

Core Components and Mechanisms

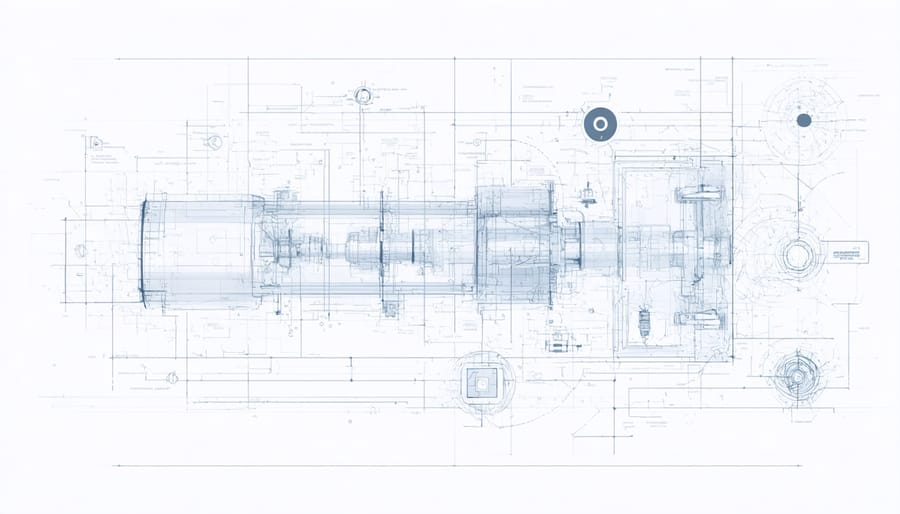

Factor technology in stone processing relies on three primary components working in harmony: the digital scanning system, automated cutting mechanisms, and precision control software. The scanning system employs high-resolution cameras and laser measurement tools to create detailed 3D maps of stone blocks, identifying natural veining patterns, potential stress points, and optimal cutting paths.

The cutting mechanism consists of advanced diamond wire saws and water jet systems that work in tandem with robotic positioning arms. These tools can adjust their cutting angle and pressure in real-time, responding to variations in stone density and composition. The precision control software serves as the brain of the operation, processing scan data and coordinating cutting movements with microscopic accuracy.

A key innovation in modern factor technology is the adaptive feedback loop system. This mechanism continuously monitors cutting progress, making instant adjustments to maintain optimal efficiency and prevent material waste. The system also incorporates specialized sensors that detect changes in stone density and composition, automatically modifying cutting parameters to ensure consistent results.

The technology’s material handling component uses vacuum-assisted lifts and computerized conveyor systems to move stone pieces safely through each processing stage. These systems are designed to minimize physical contact with the stone surface, reducing the risk of damage or marking during production.

Environmental control mechanisms play a crucial role, managing water recycling, dust collection, and temperature regulation throughout the cutting process. These systems ensure both operational efficiency and workplace safety while maintaining the highest quality standards in stone processing.

Environmental and Safety Features

Factor technology represents a significant advancement in environmentally responsible stone processing, aligning with modern sustainable stone extraction practices. This innovative approach reduces water consumption by up to 60% compared to traditional methods, while its precision cutting capabilities minimize stone waste, ensuring optimal resource utilization.

The system’s closed-loop water filtration process captures and recycles water used during cutting operations, significantly reducing environmental impact and supporting water conservation efforts. Advanced dust collection mechanisms prevent airborne particles from entering the atmosphere, protecting both worker health and the surrounding environment.

Safety features are integral to factor technology’s design. Automated cutting systems keep operators at a safe distance from cutting surfaces, while emergency stop mechanisms provide instant shutdown capabilities when needed. The technology incorporates advanced sensor systems that monitor blade conditions and automatically adjust cutting parameters to prevent accidents and equipment damage.

Temperature monitoring systems prevent overheating during continuous operation, while integrated ventilation systems maintain optimal air quality in the working environment. The technology’s sophisticated control systems also include built-in maintenance alerts, ensuring equipment remains in peak condition for safe operation.

These environmental and safety innovations not only protect workers and the environment but also contribute to operational efficiency. By reducing waste, conserving resources, and preventing accidents, factor technology represents a significant step forward in sustainable stone processing practices.

Benefits in Modern Quarrying

Increased Extraction Efficiency

Recent studies demonstrate that factor technology has significantly improved extraction efficiency in modern quarrying operations. Data collected from multiple quarries across Europe and North America shows productivity increases ranging from 25% to 40% compared to traditional methods.

For example, the Carrara marble quarries in Italy reported a 32% increase in usable stone extraction after implementing factor technology systems in 2021. This improvement resulted from more precise cutting angles and reduced waste material, allowing operators to maximize the yield from each stone block.

The technology’s impact is particularly evident in granite quarries, where extraction efficiency has improved by up to 38%. A notable case study from Quebec, Canada, documented how a quarry increased its monthly production from 800 to 1,100 cubic meters while reducing waste material by 45%.

These efficiency gains stem from several key improvements:

– More accurate identification of natural stone formations

– Optimized cutting sequences based on real-time data

– Reduced equipment wear and tear

– Lower energy consumption per extracted block

– Minimized material waste through precise splitting

The financial implications are equally impressive, with operating costs decreasing by an average of 28% across surveyed quarries. This combination of increased productivity and reduced expenses has made factor technology a crucial investment for modern stone extraction operations, delivering measurable returns within the first year of implementation.

Cost Reduction and Resource Optimization

Factor technology delivers significant cost reductions across multiple aspects of stone quarrying and processing operations. By optimizing cutting patterns and material utilization, quarries typically see a 15-20% reduction in waste material, directly impacting the bottom line. The advanced mapping and analysis capabilities help operators maximize the yield from each stone block, ensuring premium sections are identified and extracted efficiently.

Resource optimization extends beyond just material savings. The technology’s automated planning systems reduce labor hours by up to 30% compared to traditional methods, while simultaneously decreasing equipment wear and tear. Energy consumption also sees notable improvements, with some operations reporting 25% lower power usage due to optimized cutting sequences and reduced machine idle time.

The system’s predictive maintenance features help prevent costly equipment breakdowns by monitoring performance metrics in real-time. This proactive approach typically reduces maintenance costs by 20% and extends machinery lifespan by several years. Additionally, the technology’s inventory management capabilities ensure optimal stock levels, reducing storage costs and improving cash flow.

Financial benefits are particularly evident in larger operations, where the technology’s scaling capabilities can coordinate multiple extraction sites and processing facilities. Case studies show return on investment periods averaging 12-18 months, with some facilities achieving complete cost recovery within a single year of implementation.

Quality Enhancement

Factor technology has revolutionized stone quality control, delivering unprecedented consistency and excellence in natural stone production. Through advanced monitoring systems and precision-controlled splitting processes, this technology ensures that each stone piece meets exact specifications for strength, appearance, and durability.

The technology’s impact on quality enhancement is particularly evident in three key areas. First, it significantly reduces variation in stone thickness and surface texture, crucial factors in transforming modern construction practices. Second, it enables better control over natural veining and color distribution, ensuring aesthetic consistency across large stone batches. Third, it minimizes waste by optimizing stone extraction patterns based on the material’s natural formation.

Quality metrics show that factor technology-processed stones demonstrate up to 30% better uniformity in physical properties compared to traditionally quarried stone. This improvement extends to moisture resistance, thermal stability, and structural integrity, making the final product more reliable for demanding architectural applications.

The technology’s automated quality control systems continuously monitor stone characteristics throughout the extraction and processing phases, identifying and addressing potential defects before they impact the final product. This proactive approach has significantly reduced quality-related rejections while maintaining the natural beauty and character that makes each stone unique.

Real-World Applications

Factor technology has revolutionized natural stone extraction and processing across numerous successful projects worldwide. In Italy’s Carrara quarries, implementing factor technology has increased marble extraction efficiency by 40% while reducing waste material by nearly 25%. These improvements have made it possible to sustainably harvest the region’s famous white marble for modern architectural applications.

The Xiamen Stone Fair complex in China showcases factor technology’s capabilities in large-scale commercial projects. During its construction, contractors utilized automated cutting systems and digital templating to process over 50,000 square meters of granite facades with unprecedented precision. This resulted in installation time reduction by 30% and material wastage dropping to just 5%.

In North America, the Minnesota State Capitol restoration project demonstrated factor technology’s value in heritage preservation. Restoration teams employed 3D scanning and automated fabrication to create exact replicas of deteriorated limestone elements. This precision matching allowed seamless integration of new pieces while maintaining historical authenticity.

The Dubai Pearl development utilized factor technology throughout its construction phase, processing over 100,000 square meters of stone cladding. The project team achieved remarkable efficiency by implementing automated cutting systems and digital workflow management, completing stone installation 40% faster than traditional methods while maintaining superior quality standards.

These case studies highlight factor technology’s transformative impact across diverse applications. The technology has consistently delivered measurable benefits in productivity, waste reduction, and quality control. Companies implementing these systems report average cost savings of 20-30% on large-scale projects, while significantly improving workplace safety and reducing environmental impact through optimized resource utilization.

Factor technology has revolutionized the natural stone industry, transforming how we extract, process, and utilize stone materials. Through the integration of advanced automation, data analytics, and precision cutting techniques, quarrying operations have become more efficient, sustainable, and cost-effective. As the technology continues to evolve, we can expect to see even greater improvements in material yield, reduced environmental impact, and enhanced product quality. The future outlook suggests further integration with artificial intelligence, improved waste reduction capabilities, and more sophisticated modeling systems. These advancements will not only benefit industry professionals but also provide architects and designers with more versatile and sustainable stone options. As demand for natural stone continues to grow, factor technology will play an increasingly crucial role in meeting market needs while preserving our natural resources.