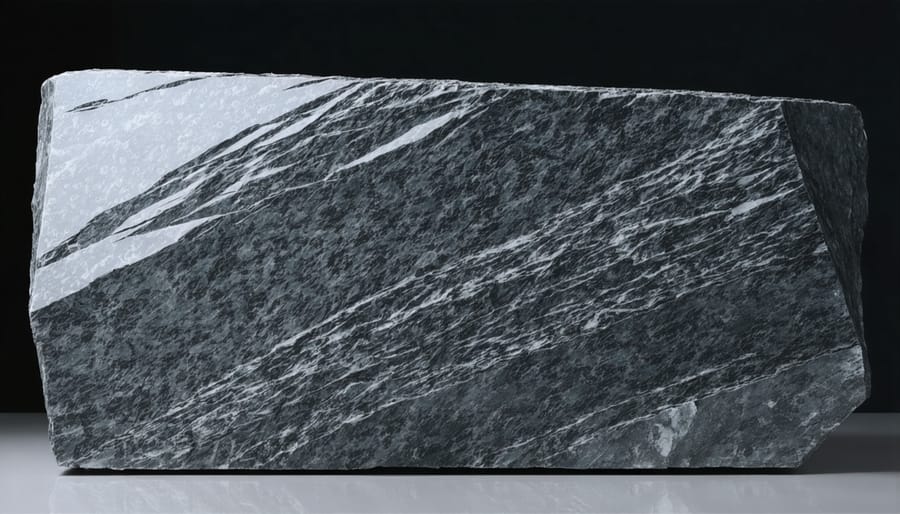

Ancient civilizations achieved engineering marvels through stone cutting techniques that continue to mystify modern experts. From the precise angles of Egyptian pyramids to the seamless joints of Incan walls, these master craftsmen shaped massive stone blocks with remarkable accuracy using surprisingly simple tools. The cultural significance of marble and other stones drove innovation across civilizations, leading to sophisticated methods that combined raw manpower with ingenious mechanical advantages.

Archaeological evidence reveals a fascinating toolkit: copper saws with sand abrasives, wooden wedges soaked in water, and stone hammers that could split massive blocks along natural faults. These fundamental techniques, refined over millennia, laid the groundwork for modern stone working practices. While today’s craftsmen benefit from diamond-tipped tools and hydraulic machinery, they still rely on principles discovered by ancient stonecutters who understood the inherent properties of stone and how to work with, rather than against, nature’s most enduring building material.

Through careful study of ancient quarries and unfinished works, we continue to uncover the brilliant solutions our ancestors developed to overcome seemingly impossible architectural challenges.

Tools of the Ancient Stone Cutters

Basic Hand Tools

Ancient stone workers relied on a surprisingly simple yet effective set of hand tools to shape and cut massive stone blocks. The most fundamental tool was the stone hammer, often made of harder stone like dolerite or later, bronze and iron. These hammers ranged in size from small palm-sized tools for detailed work to larger mauls for rough shaping.

Chisels were equally essential, evolving from copper to bronze and eventually iron. Point chisels were used for initial rough cutting and removing large sections of stone, while flat chisels allowed workers to create smoother surfaces and more precise cuts. These tools were typically struck with wooden mallets to provide better control and reduce the risk of damaging the stone.

Picks served multiple purposes in ancient stone working. Heavy picks were used to create initial trenches and separate blocks from quarry faces, while lighter versions helped in detailed shaping work. Stone workers also employed wedges and levers, often made of wood or metal, to split stones along natural faults or cut lines.

These basic tools were complemented by measuring and marking implements, including plumb bobs, squares, and scribing tools. While seemingly primitive by today’s standards, these instruments enabled ancient craftsmen to achieve remarkable precision in their work, as evidenced by surviving structures worldwide.

Specialized Cutting Implements

Ancient civilizations developed an impressive array of specialized cutting implements designed for specific stone-working tasks. Among the most notable were the bronze and later iron chisels with varying tip shapes, each serving a distinct purpose. Pointed chisels were used for initial rough cutting and creating guide lines, while flat-faced chisels enabled smoother, more controlled cuts.

The toothed chisel, featuring multiple sharp points along its edge, was particularly innovative. This tool allowed craftsmen to create textured surfaces and remove material more efficiently than single-point tools. For precise detail work, especially in softer stones like limestone and marble, fine-tipped marking tools called tracers were employed to outline intricate designs before deeper cutting began.

Another remarkable implement was the bow drill, which consisted of a wooden frame, string, and a hardened copper or bronze bit. This tool was crucial for creating holes and cylindrical cuts in stone, particularly in Egyptian and Mesopotamian architectural elements.

The pickaxe and pointed hammer, while seemingly basic, were refined over centuries to achieve optimal angles and weights for different stone types. These tools were essential for quarrying and rough shaping before finer implements were used. Craftsmen also developed specialized rasps and files, often embedded with copper or bronze teeth, for smoothing and finishing stone surfaces to remarkable precision.

Core Cutting Techniques

Splitting and Cleaving

Splitting and cleaving stone blocks was one of the most fundamental techniques used in ancient stone working. The process relied on the natural characteristics of stone, particularly its cleavage planes and inherent weak points. Ancient craftsmen would first identify these natural splitting lines by carefully examining the stone’s grain and structure.

The most common method involved creating a series of holes along the intended splitting line using bronze or iron tools. Workers would then insert wooden wedges into these holes and soak them with water. As the wood absorbed moisture and expanded, it created tremendous pressure that would eventually split the stone along the desired line.

Another technique utilized metal wedges and feathers (thin metal strips placed on either side of the wedge). Workers would drive these wedges simultaneously along the splitting line using coordinated hammer strikes. This method offered more control over the splitting process and was particularly effective with harder stones like granite.

In Egypt, archaeological evidence suggests that workers also used wooden wedges in combination with natural stone defects. They would identify existing cracks or fissures and strategically place wedges to encourage controlled splitting. This technique was especially useful when working with massive blocks in quarries.

These ancient methods were remarkably effective and continue to influence modern stone splitting techniques, though today’s tools are more sophisticated and precise.

Precise Shaping Methods

Ancient civilizations developed remarkably precise methods for shaping stone blocks and architectural elements. One of the most common techniques involved creating a series of holes along the desired cutting line using bronze or iron chisels. Workers would then insert wooden wedges into these holes and soak them with water. As the wood expanded, it created controlled pressure that split the stone along the predetermined line.

For more intricate shaping, craftsmen employed a technique called pointillage, where they used pointed tools to gradually chip away at the stone’s surface in a controlled manner. This method was particularly effective for creating detailed sculptural elements and precise geometric shapes.

The ancient Egyptians mastered the use of copper saws with abrasive sand to achieve straight cuts in harder stones like granite. By constantly adding wet sand to the cutting area, the sand particles acted as primitive cutting teeth, slowly wearing away the stone along the desired path.

Another sophisticated method involved using bronze wire combined with abrasive materials to create precise cuts. Workers would pull the wire back and forth while continuously adding sand and water, effectively creating a primitive wire saw. This technique was particularly useful for cutting deeper sections and creating complex shapes in large stone blocks.

Archaeological evidence suggests that many ancient cultures also used templates and marking tools to ensure consistency in their stone-cutting work, demonstrating an advanced understanding of geometry and dimensional accuracy.

Surface Finishing

Ancient craftsmen employed various techniques to achieve different surface finishes on stone, each serving both practical and aesthetic purposes. The most common finishing method was grinding, where artisans would use abrasive stones of varying grits to smooth rough-cut surfaces. This process typically started with coarse materials and progressed to finer ones, creating increasingly smooth surfaces.

For decorative elements, stone workers developed specialized techniques like bush hammering, which created a textured, stippled appearance by repeatedly striking the surface with a multi-pointed hammer. This technique was particularly popular in Egyptian and Greek architecture, providing both visual interest and improved grip on walking surfaces.

Polishing was reserved for the finest architectural elements and sculptural works. Craftsmen would use natural abrasives like sand mixed with water, followed by increasingly fine materials such as pumice and leather strops. The ultimate achievement was the mirror-like finish seen on many ancient Egyptian granite monuments.

Some surfaces were intentionally left rough or “quarry-faced” for specific architectural effects or to demonstrate the stone’s natural character. These techniques often involved controlled splitting or careful chiseling to maintain a rugged appearance while ensuring structural integrity.

The ancient Romans pioneered the use of different surface treatments on a single piece, combining polished and textured areas to create visual contrast and emphasize architectural features.

Regional Variations and Innovations

Egyptian Methods

The ancient Egyptians developed remarkable stone-cutting techniques that continue to mystify experts today. Their methods, deeply rooted in ancient stone ceremonies and practical engineering, enabled the construction of monuments that have endured for millennia.

One of their primary techniques involved copper chisels and stone hammers for initial rough cutting. Workers would create a line of holes along the desired cutting path, driving wooden wedges into these holes. These wedges were then soaked with water, causing the wood to expand and create controlled cracks in the stone.

For precision cutting, particularly in granite and other hard stones, Egyptian craftsmen employed dolerite balls – a remarkably hard stone used to pound and shape softer rocks. Archaeological evidence suggests they also utilized copper saws with abrasive sand, essentially creating a primitive version of modern cutting techniques.

The transportation and placement of massive stone blocks relied on ingenious systems of ramps, levers, and rollers. Limestone blocks were often cut directly from quarry faces using bronze saws and picks, with workers following natural fissures in the rock to minimize effort.

Perhaps most impressive was their ability to achieve nearly perfect right angles and smooth surfaces without modern measuring tools. They developed a sophisticated system of geometry and used plumb bobs and squares to ensure accuracy. These methods were so effective that many joints in Egyptian stonework are still tight enough that a knife blade cannot be inserted between blocks.

Greek and Roman Innovations

The Greeks and Romans revolutionized stone cutting techniques through systematic innovation and engineering prowess. Building upon earlier Egyptian methods, they developed more sophisticated tools and approaches that dramatically improved efficiency and precision in stone extraction and finishing.

Roman engineers introduced the use of iron wedges and leverage principles to split massive stone blocks along natural bedding planes. This technique, known as the “wedge and feather” method, involved drilling a series of holes along the desired splitting line and inserting metal wedges. When struck simultaneously, these wedges would create controlled fractures, allowing for more precise extraction than earlier methods.

The Romans also perfected the art of sawing stone using large bronze or iron saws with abrasive sand. This innovation enabled them to create thinner, more uniform stone slabs for construction and decorative purposes. Their ceremonial stone cutting traditions often incorporated these advanced techniques, particularly in creating elaborate architectural elements and sculptures.

Greek stoneworkers contributed significantly by developing specialized chisels and points for detailed carving. They pioneered the use of different grades of abrasives for polishing stone surfaces, achieving unprecedented levels of smoothness and luster in their marble works. Their understanding of stone’s natural properties led to innovative quarrying methods that minimized waste and maximized the use of available resources.

These classical innovations laid the groundwork for many stone-working techniques still relevant today, demonstrating the enduring impact of Greek and Roman engineering on modern stone craftsmanship.

Modern Lessons from Ancient Masters

The wisdom of ancient stonemasons continues to influence modern construction and design practices. While today’s craftsmen have access to advanced tools and technology, many of the fundamental principles established thousands of years ago remain relevant. These traditional stone working practices offer valuable insights into sustainability, durability, and aesthetic excellence.

Ancient craftsmen’s understanding of stone’s natural properties guides contemporary quarrying methods. Their technique of following natural bedding planes and fault lines reduces waste and yields stronger finished products. This approach not only conserves resources but also ensures structural integrity, a principle that modern sustainable construction embraces.

The ancient practice of hand-dressing stone surfaces provides lessons in creating unique textures and finishes that machine-cutting cannot replicate. Many high-end architectural projects now incorporate hand-finished elements, combining modern precision with traditional artistry to achieve distinctive results.

Ancient builders’ expertise in joint design and stone placement continues to inform modern construction. Their ingenious methods of fitting stones without mortar, seen in structures like Machu Picchu, demonstrate superior understanding of weight distribution and structural stability. These principles are particularly valuable in contemporary seismic-resistant architecture.

Perhaps most significantly, ancient masters’ approach to tool design influences modern stone working equipment. The basic principles behind ancient chisels and hammers remain evident in today’s pneumatic tools, though executed with greater precision and efficiency. Even modern diamond-tipped cutting tools follow patterns of wear and effectiveness first observed by ancient craftsmen.

Understanding these historical techniques enables modern stone workers to better appreciate their material’s properties and limitations. This knowledge continues to shape innovative approaches to stone cutting and construction, proving that sometimes the old ways remain the best foundation for new advances.